Nuts Bolt Manufacturing Business How To Start, Cost, Raw Material, Profit, Plan, Idea | SkillsAndTech

The nut and bolt manufacturing business has gained popularity due to the rapid Industrialization and introduction of the Capital Intensive Techniques in the Industries that are used as the Industrial fasteners to connect various machines and structures.

The nut is used as a fastener consisting of a threaded hole used in concomitance with the mating bolt to fasten together multiple parts. While a bolt is described as a threaded fastener that consists of an external male threads that needs a female thread like a nut. Both nut and bolt when used in concomitance, place two objects together and in use. Nut and bolt are complementary to each other having different uses but they are used together in manufacturing the finished products, manufacturing of furniture, and are essential for making the final products that can be used for consumption.

The Nut and bolt making business is a highly shivering industry in the Global market consisting of huge players like the USA, China, Germany, India, and Japan that are contributing greatly to the production and marketing of the nut and bolt making business. With the expansion of the nut and bolt making business globally, the nut and bolt market is expected to rise by $7706 Billion by the year 2023.

With the evolution of the automobile industry, the demand for the nut and bolt is also expected to rise at a rapid rate by the Developed economies. Not only the Automobile Industry, the manufacturing, and construction business has emerged as a huge market base for the demand of the nut and bolt all across the world. India, on the other hand, is geared up to take advantage of this booming opportunity by expanding and encouraging the nut and bolt Making Business in India.

Table of Contents

The commercial potential of Nuts And Bolts

Bolts and nuts are important items in the manufacturing industry, just like nuts and bolts are used for household purposes, so the market demand for nuts and bolts is high, so you don’t need to worry about the market potential. The company manufactures business.

The demand for the nut and bolts is influenced by the following factors

- Transportation industries

- Electrical industries

- Construction industries

- Agriculture equipment

Due to use of various MS (mild steel) and HT (high tensile) fasteners in above industries, the demand for the nut and bolts is consistently in the market, therefore if you are planning to start the fastener manufacturing business then it is a profitable business option.

Registrations & Licenses Required for Nut Bolt Manufacturing Business in India

company registration:.

You can set up a small and medium nut and bolt company as a private company or partnership.

If you start this fastening business as a sole proprietorship, you need to register your business as the owner.

To operate a business, you must register as a limited liability company (LLP) or Pvt. Limited company. At the Registry of Commerce (ROC).

Garments Making Business

Make Money From Blog

Papad Making Business

GST registration:

Registering for GST allows you to obtain a GST number that all businesses must have.

Business license:

Obtain a tread license from the local government.

Pollution certificate:

The screw and nut industry will cause pollution; therefore, you need to obtain a pollution control certificate.

MSME / SSI registration-

Fastener manufacturing is a machinery-based industry. Registering your business at the MSME / SSI Registry can provide you with government subsidies and benefits.

Trademarks:

You can protect your nut and bolt trademarks by registering trademarks.

The space (location) required to start a nut business

When starting a business, choosing the right location and area is an important factor, which will indirectly affect the growth and success of your business.

In order to ensure that raw material suppliers and target markets can enter the site, when setting up the business area, it must also be ensured that the site has facilities such as water, sewage, and electricity.

Industrial production of nuts and bolts can start from at least 800 square feet, but you must be in an industrial area or try to avoid residential areas, because some state governments do not allow you to start fastener manufacturing in residential areas. area.

Before finding a location for your nut and bolt business, please read the rules and regulations of your state government.

Raw Materials for Manufacturing Nuts Bolts

The main raw material for nut manufacturing is hexagonal rods of defined size and for manufacturing of bolt major raw material is MS round apart from these you need to buy packaging materials.

The quality metal is used in order to avoid cracking therefore while purchasing the raw material make sure that raw material must be of good quality.

The Nut is generally made up of tough metal

- Carbon steel

- Stainless steel

- Nickel alloys

- Aluminum alloy

Nut and bolt which are made up of the steel metal are coated with the zinc, cadmium, nickel, or chromium for protecting purpose.

List of Machinery used in Nut Bolt Manufacturing

Machinery is another important factor that effects on the production of the product and indirectly affects the success of your business

There are different types of machinery are available in the market you have to choose the right machinery according to the investment and production demand for your fastener manufacturing industry.

If you don’t know how to handle the machines then ask the machinery supplier for the onsite training.

The machinery required for the nut and bolt manufacturing business is as follow

List of machinery required for nut and bolt manufacturing business.

- Double stroke solid die cold head forging machine

- Head trimming machine

- Thread rolling machine

- Bull block wire drawing machine

- Straightening machine

- Power press

- Planting tank

- Steel polishing barrel with an electric motor

- Automatic nut forming plant

- Nut tapping machine

- Wire pointing machine

- Weighing scale

Manpower Requirement

The nut and bolt business requires the manpower together with the proper training of the machine usage, how to handle the equipment, and training how to handle them with proper care and precautions.

Following are the manpower that is required to start a nut and bolt manufacturing business-

- Three Unskilled Labors

- 2 Semi-Skilled Labors

- 6 Skilled Labors

- One Accountant For Handling The Accounts Department

- One Production Manager

Tea Shop business

Poultry Farm Business

Jeans Making Business

Variants to keep in mind before starting a Nut and Bolt Manufacturing Business

Before establishing your nut and bolt manufacturing business, the person must keep the following variants in mind and make a business plan for the growth and expansion of his Business-

One Must Analyze Why Customers Should Buy Or Use Their Products. Whether Their Products Are Affordable Or Not And Many Other Factors That Affect The Value Proposition Of His Nut And Bolt Manufacturing Business. The Customers Must Be Targeted To Increase The Demand Of The Nut And Bolt Manufacturing Business. Following Are The Targets To Be Set;

- The Electrical Industry

- The Transportation Industry

- The Automobiles Industry

- The Construction Industry

- Households, Domestic, And Garages

- Furniture Making And The Wood Industry

- The Metal Industry

- The Steel Fabricating Industry

With The Vast Market Demand Of The Nut And Bolt, One Must Always Review His Competition To Cater To The Prevalent Market Needs And Requirements.

Making A Proper Marketing Strategy Is One Of The Most Important Steps To Start A Nut And Bolt Manufacturing Business In India. Various Measures Must Be Taken To Promote Sales And Increase The Long-Term Contracts From Various Leading Industries.

Investment and Profit Margin

Before starting a nut and bolt manufacturing business, a person must make sure that he arranges a Fixed Capital Investment of Rupees 20 lakh and a Working Capital Investment of Rupees 5 Lakh. The Investment required for starting a business can also be availed by the banks through loans or our Organization Aatmnirbhar Sena.

The Aatmnirbhar Sena is also providing financial assistance to the budding and young entrepreneurs who are willing to establish their nut and bolt manufacturing business and helping the Indian Government in making India Self-reliant.

The net profit that can be obtained from starting the nut and bolt making business is about Rupees 7 lakh per year while the investment return on the business is more than 21 percent.

One of the major reasons for the expansion of this form of Business is the versatile nature of the nuts and bolts as they are the intermediary products that to a greater extent ensure their applications in almost every industry in India.

Nuts Bolt Manufacturing Process

Step1 cold heading, 1. straightening of wire:.

Wire is fed from the mechanical coil through straightening machine

2. Cutting of wire:

The straight wire goes through the machine that cut the wire into the required size and dies cut the head of the screw into a predefined shape.

3. Creating screw blank:

The heading machine create screw head which consist of open or closed dies that either required one punch or two punch ( closed dies create more accurate screw bank)

The cold heading machine produces 150 to 600 screw blanks per minute

Step 2 Thread rolling

4. thread cutting:.

The screw blanks are fed into the thread cutting dies from a vibrating hopper.

Tissue paper Making Business

Jawed Habib

First Cry Franchisee

The vibrating hopper guide the screw blanks down a chute to dies and make sure that the screw blank incorrect feed position

5. Blank cutting:

The screw blank is cut down using one of the following methods

Reciprocating die method: in this method, two dies are used to cut the screw thread, where one die is stationary and another is move In a reciprocating manner and screw blank is rolled between two dies

center less cylindrical die method: in this method, screw blank is rolled between two to three round dies to create the threads

planetary rotary die method: in this method, planetary rotary dies to hold the screw blank stationary and die cutting machines are rolled around the screw blank.

All of these methods produce high-quality screw.

Step 3 Packaging

6. Once nut and bolts are produce packed them into the cartoon packed box and dispatch.

Where/How to sell Nuts and Blot.

Nut and bold is the product for which you can’t use regular branding and promoting strategies.

You need to contact with the industry and retailers who will purchase your fastener and will help you to introduce your fastener brand to other clients

Local market (Retail market, Garages)

You can sell your nut and bolt product to your local retailer market.

Wholesale market for Nuts Bolts

You can sell your nut and bolt product to the wholesale market in bulb amount.

Online market for Nuts Bolts

B2b websites:.

Register your business on B2B websites like

- Exportersindia

Etc. you can sell your product on bulk orders.

B2C Websites:

Register your business on B2C websites like

etc. where you can sell your product directly to the customer.

Brand and Uniqueness

You cannot use the branding strategies and promotions that are used for other products because fastener is the product that sold on the basis of the quality of the product, therefore, make sure that you are producing the high-quality fastener.

When you are selling the fasteners to the client ask them for other contacts where you can sell your nut and bolt product.

Try to expand your client base using your recent customers.

If they like your product they definitely help you to sell out more by simply telling other people about your product.

How to Start Nuts Bolt Manufacturing Business | SkillsAndTech

You May Also Like

Ice Cream Shop Business Cost, How to Start, Paperwork, Product Details | SkillsAndTech

How To Start Sugarcane Juice Business | SkillsAndTech

How to Start a Wine Business | SkillsAndTech

Join our WhatsApp channel for Information

How to Start Nuts And Bolts Making Business ?

Market potential and uses, types of bolts & nuts and their uses, licenses required, investment required, profits made, target consumers, area required, raw material, machinery & manpower required, business model and growth, profit margin.

- The demand for modern fasteners, nuts and bolts in manufacturing finished products, is like the demand for wood in manufacturing furniture, it is a derived demand which is essential for the products to be used for final consumption.

- Nuts and bolts have their own specific use but cannot be used without the other. A Nut is a a type of fastener with one threaded hole, a Bolt on the other hand is a metallic with around stem threaded into the hole of a nut. Both when used in conjunction are used to put two objects together and to function.

- The global fastener industry is highly fragmented and consists of many huge players contributing to its production like the USA, Germany, China, Japan and India. This market is expected to value at ₹ 7706 billion by the end of 2023.

- Because of a raising demand of fasteners in automotive industries along with the constructional and manufacturing industries in emerging economies who want to be addressed as “Developed Economies” like Indonesia, Brazil etc. India, is seeking to take advantage of the need for nuts and bolts particularly and generate demand from these nations in the forecasted periods

- And there’s no better time for you than now to get your toes dipped in this industry and this is how.

- The market for nuts and bolts is swamped by industrial and manufacturing companies who require nuts and bolts both as an intermediary product and to bring together a finished product.

- Moreover with the rising need of Indian industries to be technologically independent has made increased the demand for these fasteners for them to be self sufficient in terms of machines, equipment’s they own.

- The different types of nuts and bolts have made their applications implementative across all the industries and increased its potential in the following ways.

Read More : How to Start Cement Dealership Business ?

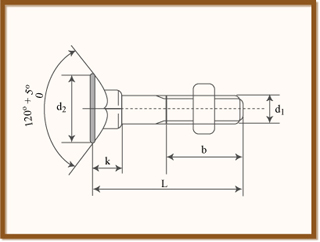

Carriage bolt : With its round head is used to connect the prices of wood.

Machine screw bolt : It is used for the purpose of general utility.

Stud bolt : It is used when additional length is required.

J-bolt, U-bolt, eyebolt: These are used to support hanging items and have no heads.

Square / hex nut : It is used because of its square or hexed shape, thickness and the fact that it comes in varieties.

Wing nut : It is used when materials are used to be removed and replaced to often, it can be loosened or tightened by hand.

Log nut : Similar to square nut nut comes with threaded nylon inserts in order to prevent loosening.

The licenses require to enter into a nuts and bolts manufacturing business would be:

- Trade licence for local municipal authorities.

- MSME and SSI registration.

- Factory license.

- NOC by state pollution control board.

- GST registration.

- PAN, Aadhar card.

The consumer market for the nuts and bolt manufacturing business in India is widespread across the capital intensive industries, which means every exiting industry.

The target customers are as follows :

Transportation industries : Make use of nuts and bolts in railways, aircrafts , wagons, bicycles , automobiles etc.

Electronic industries: These apply the properties of nuts and bolts in manufacturing of transformers, electrical motors, fans etc.

Construction and building industries: There demand for nuts and bolts comes form the demand for construction of bridges, fabrication of various steel structures etc.

Other heavy and light industries: Industries like steel, wooden, furniture and machine tools, agricultural tools etc require nuts and bolts as their raw material to produce finished product.

Read more : 10 Most Profitable Manufacturing Business Ideas

The area required to set up a nut and bolt manufacturing business would be 1600 sq m .

The raw materials required to run a nuts and bolts business would be

- Wire/rod 6mm-18mm diameter

- Polishing material

- Packing material

- Water and electricity

The machinery involved in running a nuts and bolts making business is as follows

- Double stroke solid die cold forging machine

- Head trimming machine

- Thread rolling machine

- Wire pointing machine

- But tapping machine

- Steel polishing dyer machine

- Bull block wire drawing machine

- Cooler and boiler

The manpower required to run a nuts and bolts manufacturing business would be:

- 3- unskilled workers

- 2- semi skilled workers

- 6- skilled workers

- 1- accountant

- 1- production manager

Moreover these workers must also be provided with training in terms of machine usage, equipment handling, safety and precaution measures etc

The business model of a nuts and bolts manufacturing business can be defined using 4 variants :

Value proposition: The unique selling point and the value which a nuts and bolts making business would provide you with is :

- It’s affordability and essentialism across every industry.

- The fact that it is in demand by the industries for producing machines for those industries who also demand nuts and bolts for conversion of raw materials to finished products.

Target consumers: The target consumers for your nuts and bolts making business would be:

- Transportation industries.

- Electrical industries.

- Automotive industries.

- Constructional industries.

- Households, garages.

- Metal and steel fabrication industries.

- Furniture and wood industries.

Competitor review: The competition in the nuts and bolts making industries is not as fierce as it has a vast market to cater to. However the leaders in this market in India are :

- Lakshmi precision screw ltd.

- KOVA fasteners pvt ltd.

- Sundaram fasteners ltd.

Marketing strategy: The marketing strategy for the nuts and bolts making business to increase its sales Would be.

- Sales promotion measures : Trade and cash discounts on bulk purchases.

- Differential predicting strategy to get long term contracts from industries by offering them price cuts etc.

The nuts and bolts making business has the potential and bears witness to the following growth prospects:

- The global CAGR of the nuts and bolts industry is expanding at the rate of 6.5% since 2018.

- The Indian nuts and bolts market is expected to be of a value of ₹460 billion by 2023 and expanding at a CAGR of 9.6% from 2018.

- India’s development and constructional sector go hand in hand thereby increasing the demand for these fasteners to become technologically independent and self sufficient.

Read More : How To Start Furniture Making Business ?

The bits and bolts industry is likely to yield a profit margin of 8.5% .

Let’s get into the “nuts and bolts” of this business if you hadn’t made a decision to own one already:·

- Firstly, the use of nuts and bolts as products and also as auxiliary products has ensured implement of its applications across almost every industry in India.

- Secondly, the Make in India and local is vocal initiatives have encouraged all the industrial and MSMEs to set up plants for the products they’ve been importing thereby deriving the demand for nuts and bolt fasteners.

- Lastly, the minimal investment, high inventory turnover ration and bulk orders are to your advantage.

Sign Up For Our Newsletter

Disclaimer :The information contained in this Article is for general information purposes only. The information is provided by StartupYo (SAB Weblabs Pvt.Ltd). While we endeavour to keep the information up to date and truest to the best of our knowledge, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

Share this post:

You might also like:.

Best Detergent Powder Making Classes In Ahmedabad

Best Detergent Powder Making Classes In Jaipur

Best Detergent Powder Making Classes In Chennai

Provide your details.

Get instant access to detailed competitive research, SWOT analysis, buyer personas, growth opportunities and more for any product or business at the push of a button, so that you can focus more on strategy and execution.

Table of contents, launching your own bolt and nut manufacturing business.

- 11 June, 2024

Understanding the Industry

Before diving into the process of starting your own bolt and nut manufacturing business, it is crucial to gain a comprehensive understanding of the industry. This section provides an overview of the bolt and nut business and explores the market analysis.

Overview of Bolt and Nut Business

The bolt and nut business is an integral part of the manufacturing and construction sectors. Bolts and nuts are essential components used to fasten and connect various structures, machinery, and equipment. From large-scale construction projects to everyday consumer products, the demand for bolts and nuts remains consistent.

The manufacturing process for bolts and nuts involves various stages, including material sourcing, forming, threading, heat treatment, and surface finishing. This intricate process ensures that the produced bolts and nuts meet the required specifications and standards.

Starting a bolt and nut manufacturing business requires a sound business plan, a thorough understanding of the industry, and the ability to deliver high-quality products. To learn more about developing a business plan, check out our article on bolt and nut business plan .

Market Analysis

Conducting a market analysis is crucial to identify potential customers, assess competition, and understand the market dynamics. Here are some key factors to consider:

Market Size : The bolt and nut industry is a significant part of the manufacturing sector, serving diverse industries such as automotive, aerospace, construction, and more. The market size is influenced by economic conditions, infrastructure development, and industrial growth.

Competition : The bolt and nut industry is highly competitive, with both local and international players. It is important to identify key competitors, analyze their strengths and weaknesses, and find ways to differentiate your business. Consider establishing strategic partnerships with bolt and nut distributors to expand your reach.

Market Trends : Stay informed about the latest market trends and technological advancements in bolt and nut manufacturing. This includes exploring innovative production techniques, environmentally friendly practices, and the use of advanced materials. Adapting to market trends can give your business a competitive edge.

Business Opportunities : Identify potential business opportunities within the bolt and nut industry. This may include catering to niche markets, offering specialized products, or exploring export opportunities. Researching bolt and nut business opportunities can provide valuable insights.

Remember, the market analysis is an ongoing process. Continuously monitor industry trends, customer needs, and market dynamics to adapt your business strategy accordingly. By understanding the industry and conducting a thorough market analysis, you can position your bolt and nut manufacturing business for success.

Planning Your Business

Before launching your own bolt and nut manufacturing business, it is essential to have a solid plan in place. This section will cover the key aspects of planning your business, including the essentials of a business plan and the legal requirements involved.

Business Plan Essentials

Creating a comprehensive bolt and nut business plan is crucial for the success of your venture. It serves as a roadmap for your business, outlining your goals, strategies, and financial projections. Here are some essential elements to include in your business plan:

Executive Summary: Provide a concise overview of your business, including its mission, vision, and key objectives. This section should grab the reader’s attention and highlight the unique aspects of your business.

Market Analysis: Conduct a thorough bolt and nut industry analysis to understand the market landscape, competition, and potential customers. Identify your target audience and explore their needs, preferences, and buying patterns.

Products and Services: Describe the specific types of bolts and nuts you plan to manufacture and the range of products or services you will offer. Highlight any unique features or advantages that set your products apart from competitors.

Marketing and Sales Strategy: Outline your marketing and sales strategies to reach your target audience and promote your products. This may include online and offline marketing tactics, such as advertising, trade shows, and digital marketing campaigns.

Operations and Management: Explain how you will set up and manage the day-to-day operations of your business. Define your organizational structure, roles and responsibilities, and the expertise of your management team.

Financial Projections: Provide a detailed analysis of your projected financials, including revenue forecasts, expenses, and profitability. This section should also include information on your startup costs, funding sources, and potential return on investment.

Remember, a well-crafted business plan not only helps you stay focused and organized but also serves as a valuable tool when seeking funding or partnerships.

Legal Requirements

To start a bolt and nut manufacturing business, you must comply with various legal requirements. These may vary depending on your location, so it’s important to research and understand the specific regulations applicable to your area. Here are some common legal considerations:

Business Registration: Register your business with the appropriate government authorities. Choose a suitable business structure, such as a sole proprietorship, partnership, or limited liability company (LLC), and complete the necessary registration and licensing procedures.

Permits and Certifications: Obtain any permits and certifications required to operate a manufacturing business. This may include environmental permits, safety certifications, and compliance with industry standards.

Intellectual Property Protection: Consider protecting your intellectual property, such as trademarks, patents, or copyrights, to safeguard your unique designs, processes, or brand identity.

Employment Laws: Familiarize yourself with employment laws and regulations pertaining to hiring, wages, working conditions, and employee benefits. Ensure compliance with labor laws to maintain a healthy and lawful work environment.

Health and Safety Regulations: Implement proper health and safety protocols to ensure a safe working environment for your employees. This may include providing protective equipment, establishing safety procedures, and adhering to industry-specific safety standards.

Consult with legal professionals or business advisors to ensure full compliance with all legal requirements and to seek guidance specific to your location and circumstances.

By addressing the essentials of a business plan and understanding the legal requirements, you will be well-prepared to lay a strong foundation for your bolt and nut manufacturing business.

Setting Up Operations

To successfully launch your own bolt and nut manufacturing business, you need to carefully plan and set up your operations. This involves understanding the manufacturing process and acquiring the necessary equipment and tools.

Manufacturing Process

The manufacturing process of bolts and nuts involves several steps to ensure the production of high-quality products. These steps typically include:

Wire Drawing : The process begins by drawing steel wire through a series of dies to reduce its diameter and create a uniform shape.

Heading : The wire is then cut into specific lengths and fed into a heading machine. The machine uses high-pressure to shape the wire into the head of the bolt or nut.

Thread Rolling : Next, the threaded portion of the bolt or nut is created by rolling the semi-finished product between two dies. This process strengthens the threads and ensures their accuracy.

Heat Treatment : To enhance the mechanical properties of the bolts and nuts, heat treatment is applied. This involves heating the products to a specific temperature and then cooling them rapidly or slowly, depending on the desired properties.

Surface Coating : Surface coatings, such as zinc plating or galvanizing, are applied to protect the bolts and nuts from corrosion. These coatings also provide an aesthetic finish.

Quality Control : Throughout the manufacturing process, strict quality control measures should be implemented to ensure that the bolts and nuts meet the required specifications and standards. This includes inspecting dimensions, thread quality, hardness, and surface finish.

Equipment and Tools

To set up your bolt and nut manufacturing operations, you will need the following equipment and tools:

Wire Drawing Machine : This machine is used to draw steel wire to the desired diameter and shape.

Heading Machine : A heading machine is essential for shaping the wire into the head of the bolt or nut.

Thread Rolling Machine : This machine is used to create the threaded portion of the bolts and nuts by rolling the semi-finished products between dies.

Heat Treatment Furnace : A heat treatment furnace is necessary to heat the bolts and nuts to the required temperature for enhancing their mechanical properties.

Surface Coating Equipment : Depending on the chosen coating method, you will need equipment for applying zinc plating, galvanizing, or other protective coatings.

Quality Control Tools : To ensure the quality of your products, you will need measuring instruments such as calipers, micrometers, hardness testers, and surface finish analyzers.

By investing in the appropriate equipment and tools, you can establish a smooth and efficient manufacturing process for your bolt and nut business. It is crucial to choose reliable suppliers and manufacturers for your equipment to ensure their quality and durability.

As you continue to grow your business, you may consider expanding your operations by adding additional machinery and tools that can increase production capacity. For more information on scaling your business and exploring diversification opportunities, refer to the relevant sections in this article.

Remember, the success of your bolt and nut manufacturing business relies not only on the manufacturing process and equipment but also on your understanding of the industry, a well-developed business plan , and effective marketing strategies .

Quality Control

Ensuring the quality of your bolt and nut manufacturing business is paramount to its success. Implementing effective quality control measures is essential to meet customer expectations and maintain a competitive edge in the market. In this section, we will explore the importance of quality control and the significance of adhering to industry standards and certifications.

Importance of Quality Control

Quality control plays a vital role in the manufacturing process of bolts and nuts. It encompasses a range of activities aimed at monitoring and improving the quality of products, ensuring they meet specified requirements and standards. Implementing robust quality control measures offers several benefits for your business, including:

Customer Satisfaction: Delivering high-quality products consistently fosters customer satisfaction and loyalty. Meeting or exceeding customer expectations establishes a positive reputation for your bolt and nut manufacturing business, helping to attract and retain customers ( Brown et al. ).

Cost Reduction: Effective quality control helps identify and rectify defects early in the manufacturing process, reducing rework, scrap, and waste. By minimizing production errors, you can optimize your resources, lower costs, and improve overall operational efficiency.

Compliance with Regulations: Quality control ensures that your products meet industry-specific regulations, standards, and safety requirements. Compliance with these regulations helps to protect your customers and your business from legal and regulatory issues.

Brand Reputation: Consistently delivering high-quality products builds a strong brand reputation. Positive word-of-mouth referrals and customer testimonials can enhance your market position, attracting new customers and business opportunities ( Smith ).

Standards and Certifications

Adhering to industry standards and obtaining relevant certifications can further enhance the credibility and marketability of your bolt and nut manufacturing business. These standards and certifications serve as benchmarks for quality control, helping you maintain consistent product quality and meet customer expectations.

One widely recognized standard in the bolt and nut manufacturing industry is the International Organization for Standardization (ISO) 9001. This certification demonstrates your commitment to quality management systems and ensures that your business follows globally accepted quality control practices ( Garcia ).

Additionally, there may be industry-specific standards and certifications relevant to your bolt and nut manufacturing business. For instance, the American Society of Mechanical Engineers (ASME) sets standards for bolts and nuts used in various applications. Adhering to these standards can provide your business with a competitive advantage and instill confidence in your customers ( Johnson ).

By implementing quality control measures and obtaining relevant certifications, you can not only meet customer expectations but also enhance your business’s credibility and reputation in the market. Emphasizing quality control as a core aspect of your operations will help differentiate your bolt and nut manufacturing business and position it for long-term success.

Marketing Strategies

To successfully launch and grow your bolt and nut manufacturing business, it is essential to develop effective marketing strategies. Two key aspects of marketing include identifying your target audience and implementing promotional tactics.

Target Audience

Identifying your target audience is crucial for creating focused marketing campaigns and maximizing your business’s reach. The target audience for your bolt and nut manufacturing business may include industries such as construction, automotive, machinery, and more. Understanding the specific needs, preferences, and challenges of your target audience will help you tailor your marketing efforts to effectively connect with potential customers.

To further refine your target audience, consider factors such as geographic location, company size, and purchasing power. Conducting market research and analyzing industry trends will provide valuable insights into the characteristics and demands of your target audience. This information will guide your marketing strategies and ensure that your message resonates with the right people.

Promotional Tactics

Implementing effective promotional tactics will help raise awareness about your bolt and nut manufacturing business and attract potential customers. Here are some tactics to consider:

Online Presence : Establishing a strong online presence is crucial in today’s digital age. Create a professional website that showcases your products, services, and company information. Optimize your website with relevant keywords to improve search engine visibility. Utilize social media platforms to engage with your target audience, share industry-related content, and promote your products.

Industry Events and Trade Shows : Participate in industry events, trade shows, and exhibitions to showcase your products and connect with potential customers face-to-face. These events provide an excellent platform to network with industry professionals, build brand recognition, and generate leads.

Content Marketing : Develop informative and engaging content, such as blog posts, articles, and tutorials, that highlight the benefits and applications of your bolt and nut products. Share this content on your website, social media channels, and industry forums to establish yourself as an authority in the field.

Direct Marketing : Reach out to potential customers directly through targeted email marketing campaigns or direct mail. Personalize your messages to address their specific needs and offer solutions that your bolt and nut products can provide.

Partnerships and Collaborations : Explore partnerships with complementary businesses, such as bolt and nut distributors, to expand your reach and tap into their existing customer base. Collaborate with industry influencers or experts to endorse your products and increase credibility.

Remember to track the effectiveness of your promotional tactics by monitoring key performance indicators (KPIs) such as website traffic, lead generation, and sales conversions. Regularly analyze the results and make adjustments to your marketing strategies as needed.

By targeting the right audience and implementing a mix of promotional tactics, you can effectively market your bolt and nut manufacturing business and achieve sustainable growth. Stay updated on industry trends and business opportunities to ensure that your marketing strategies align with the evolving needs of your target audience.

Business Growth

As your bolt and nut manufacturing business starts to establish itself, it’s important to have plans for its future growth. This section will explore two key aspects of business growth: scaling your business and diversification opportunities.

Scaling Your Business

Scaling your bolt and nut manufacturing business involves increasing its size and capacity to meet the growing demand for your products. There are several strategies you can employ to scale your business effectively:

Optimize Operations : Continuously evaluate and refine your manufacturing processes to increase efficiency and productivity. Look for ways to streamline operations, reduce waste, and improve overall output.

Invest in Technology : Embrace technology advancements that can enhance your manufacturing capabilities. This may include upgrading machinery and equipment, implementing automation systems, or adopting digital solutions for inventory management and customer relationship management.

Expand Your Market Reach : Explore new markets and customers to expand your customer base. Consider targeting industries or geographical areas that have a high demand for bolts and nuts. Develop marketing strategies to reach these new audiences effectively.

Build Strategic Partnerships : Collaborate with other businesses in the industry, such as bolt and nut distributors, to expand your reach and leverage their distribution networks. Strategic partnerships can help you access new markets and increase your sales potential.

Invest in Workforce Development : Invest in training and development programs for your employees to enhance their skills and knowledge. A skilled workforce will contribute to improved production efficiency and product quality.

Remember, scaling your business requires careful planning and execution. Develop a detailed bolt and nut business plan that outlines your growth strategies, financial projections, and milestones to track your progress effectively.

Diversification Opportunities

Diversification involves expanding your business into new product lines, markets, or industries. This strategy can help reduce risk by not relying solely on a single product or market. Here are some diversification opportunities to consider:

Product Diversification : Explore the possibility of manufacturing related products that complement your core bolt and nut offerings. This could include fasteners, screws, or other industrial components. Conduct market research to identify potential opportunities and assess their viability.

Geographical Diversification : Consider expanding your business into new regions or countries. Research markets with significant demand for bolts and nuts and evaluate the feasibility of establishing a presence in those areas.

Industry Diversification : Look for opportunities to supply bolts and nuts to different industries. For example, consider sectors such as automotive, construction, or aerospace that have a consistent demand for fasteners. Adapting your products to meet industry-specific requirements can open up new avenues for growth.

Value-Added Services : Explore opportunities to offer value-added services alongside your bolt and nut manufacturing business. This could include providing custom packaging, assembly services, or offering specialized coatings or finishes for your products.

Diversification can be a strategic move to tap into new markets and revenue streams. However, it requires careful market research, planning, and a thorough understanding of the potential risks involved. Consider seeking expert advice or conducting thorough market analysis to evaluate the feasibility of diversification opportunities.

By focusing on scaling your business and exploring diversification opportunities, you can position your bolt and nut manufacturing business for long-term growth and success in the industry. Regularly assess market trends, customer needs, and industry developments to stay ahead of the competition and adapt your strategies accordingly.

Perform Deep Market Research In Seconds

Automate your competitor analysis and get market insights in moments

Create Your Account To Continue!

Automate your competitor analysis and get deep market insights in moments, stay ahead of your competition. discover new ways to unlock 10x growth., just copy and paste any url to instantly access detailed industry insights, swot analysis, buyer personas, sales prospect profiles, growth opportunities, and more for any product or business..

- Best Products

How to Start Nuts and Bolts Manufacturing Business

- March 12, 2023

- by Next What Business Research Team

Nuts bolts making business comes under the light engineering product manufacturing. Generally, nuts and bolts are a type of industrial fasteners used in various products, machines, structures, etc. Nuts and bolts consist of a major link in the family of industrial fasteners.

Generally, every industry uses these items on a regular basis. Bolt is a piece of a metal rod, whose one end is unsettled and another end is threaded. The nut is the item that rolls on these threads.

Check : Top Small-Scale Manufacturing Business Ideas

Nuts and bolts are available in various shapes, designs, and sizes. Nuts and bolts are essential items for the fastening purpose in industries where the replacement of pieces and parts is necessary.

There are many industries producing these nuts and bolts of various sizes, but the demand is also increasing as well as the raw material for the products is easily and indigenously available. Alike any manufacturing business nuts and bolts making business opportunity also demands strategic planning.

Nuts and Bolts Manufacturing Business Project Plan

Having knowledge of mechanical engineering is a plus but it is not mandatory. With the limited capital investment, any individual can initiate nuts bolts making unit.

1. Nuts Bolts Making Market Potential

The demand for nuts and bolts is influenced by the following factors:

- Transportation industries, Railways, aircraft, wagons, bicycles, automobiles, bodybuilders, etc.

- Electrical industries like the manufacturing of transformers, electric motors, fans, etc.

- Building activities such as the construction of bridges, fabrication of various steel structures, etc.

- Other heavy and light industries, steel and wooden furniture, machine tools, agricultural machines, and agricultural implements, etc.

Various types of MS and HT nuts and bolts are used in the above sectors. Therefore, these items have a prominent market demand for the development of these industrial segments.

2. Nuts Bolts Making Business Registration

Registration of your business with ROC is the first necessary part of initiating nuts bolts-making business. You will need to obtain a Trade License from the local Municipal Authority. Register your business with DIC as SSI Unit.

Apply for ‘consent to establish’ and ‘consent to operate’ both from the Pollution Control Board. If you want to establish a full-scale factory set up you should apply for Factory License. You will need to get GST Registration .

3. Raw Materials & Machinery

In manufacturing nuts, the main raw material is the hexagonal rod of the desired size. For bolt manufacturing, the required major raw material is MS rounds. Apart from this, you will need to arrange packaging consumables.

In starting nuts bolts making business you will need to establish machinery such as Double stroke solid die cold head forging machine, Head trimming machine, Thread rolling machine, bull block wire drawing machine, straightening machine, Power press, Planting tank, Steel polishing barrel with an electric motor, Automatic nut forming plant, Nut tapping machine, Weighing scale, etc. Procure the machinery from a reliable supplier. Ask them for onsite training.

4. Nuts Bolts Manufacturing Process

In nuts manufacturing, you will need to procure the hexagonal rod of the desired size. And then, cut the nuts on the automatic nut-cutting machine. Cut nuts blanks are drilled and tapped on the nut-tapping machine. Finally, debug the nuts in the polishing barrel.

In bolt making, you have to make the procured MS rounds straight. The rounds are picked in the acid tanks, washed, and drawn into a drawing machine. The cleaned rod is fed into the cold heading machine. In the machine, cut one end of the rod to the desired length with a cutting stroke. And simultaneously the head formation takes at another end.

5. Area Required

You will need a minimum area of 1000 Sq.ft to establish the manufacturing production unit. The reason is mainly that various types of machinery need to be installed.

6. Cost & Investment to Start Nuts & Bolts Manufacturing Unit

The minimum investment needed to set up this manufacturing unit will be around 20 Lacs in Indian Rupees. It includes machinery, licenses, and manpower costs.

7. Arrange Funds

If you are short in budget, there will be a need to approach banks and other loan providers to secure funding. You must have your business project plan ready before pitching for funds from financial institutions.

You can also try personal loan apps for instant funding. Also, do not forget to apply for a credit card for handling small business-related expenses.

8. Where to Find Nuts and Bolts Manufacturers?

The best way to find manufacturers of nuts and bolts nowadays is by searching online. You will find plenty of machine manufacturers just by browsing search engines like Google. The top places to find are Indiamart, Trade India, Alibaba, etc.

Become A Bolts And Nuts Supplier — Business Ideas

by Planet Bolt | Jan 15, 2024 | Hardware TIps | 0 comments

Embarking on the journey of becoming a bolts and nuts supplier opens up a realm of possibilities in the construction and manufacturing industry.

If you’re intrigued by the idea of delving into this business, this guide will provide you with insights on how to start, the profitability of selling nuts and bolts, effective selling strategies, and a glimpse into the profit margins in the nut and bolt business.

How to Start a Nut and Bolt Business

Starting a nuts and bolts business involves several key steps:

– Market Research:

Conduct thorough market research to understand the demand for nuts and bolts in your target area. Identify potential competitors and gaps in the market that your business can fill.

– Business Plan:

Craft a comprehensive business plan that outlines your goals, target market, marketing strategies, and financial projections. A well-thought-out plan will guide you through the early stages of your business.

– Legal Formalities:

Register your business, obtain any necessary licenses or permits, and ensure compliance with local regulations. This step is crucial for establishing a legitimate and trustworthy business.

– Supplier Relationships:

Build strong relationships with reliable suppliers to ensure a steady and high-quality inventory of nuts and bolts. The reliability of your suppliers directly impacts the reliability of your business.

– Online Presence:

Establish an online presence through a website and social media platforms. In the digital age, having a strong online presence is essential for reaching a wider audience.

Is Selling Nuts and Bolts Profitable?

The profitability of selling nuts and bolts largely depends on various factors, including market demand, competition, and operational efficiency. As construction and manufacturing sectors continue to grow, the demand for nuts and bolts remains consistent. By offering quality products, excellent customer service, and competitive pricing, your business can tap into this profitability.

Selling Strategies: Nuts and Bolts of Effective Sales

– quality assurance:.

Emphasize the quality of your products. Construction and manufacturing professionals prioritize reliable and durable nuts and bolts, making quality a key selling point.

– Customer Relationships:

Cultivate strong relationships with your customers. Understand their needs, provide personalized service, and establish your business as a trusted partner in their projects.

– Diversification:

Explore opportunities for diversification by offering a variety of nuts, bolts, and related products. This can attract a broader customer base and increase revenue streams.

– Online Marketing:

Leverage online marketing strategies to reach a wider audience. Utilize social media platforms, search engine optimization (SEO), and online advertising to enhance your business visibility.

Navigating Profit Margins: Nut Bolt Business

Profit margins in the nut and bolt business vary based on factors such as product type, market conditions, and competition. On average, profit margins can range from 20% to 50%. Efficient operations, competitive pricing, and effective cost management are key elements that influence your profit margins.

Tapping into the robust construction and manufacturing sectors

Becoming a nuts and bolts supplier is not just a business idea; it’s a pathway to tapping into the robust construction and manufacturing sectors. By starting with a solid plan, focusing on quality, implementing effective selling strategies, and understanding the dynamics of profit margins, you can carve a successful niche in this essential industry.

Seize the opportunity, tighten the bolts, and embark on a journey that not only connects materials but also connects you to the profitable world of nuts and bolts supply.

Want to partner with us? Contact us today for any inquiries, by clicking here

More Articles For You

Common Applications of Bolts and Nuts in Construction

Key Concepts in Bolts and Nuts Installation

Maintenance Tips for Long-Lasting Bolts and Nuts Performance

Exclusive deals & offers.

Subscribe and be the first to get amazing deals!

Thank you for subscribing to PlanetBolt's newsletter. You will now receive latest updates from us.

Submit a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

DONGGUAN MIKE HARDWARE CO., LTD.

How to start a fastener business successfully.

Starting a fastener business successfully requires careful planning and strategic decision-making. This article aims to provide an objective and impersonal analysis of the key factors involved in launching and managing such a venture.

By examining the profitability of selling nuts and bolts, exploring the industries that heavily rely on fasteners, and delving into the intricacies of manufacturing screws and precision fasteners, this piece offers valuable insights for entrepreneurs looking to enter this industry.

Additionally, it highlights the importance of sourcing reliable suppliers as a crucial aspect of ensuring long-term success in the fastener business.

1.Starting a Fasteners Business

Starting a fasteners business requires careful planning, market analysis, and a comprehensive understanding of industry trends and customer demands. A thorough business plan is essential to outline the goals, strategies, and financial projections of the venture. Market analysis involves studying the target market, identifying potential customers, and evaluating competition. Understanding industry trends helps in identifying emerging opportunities and adapting to changing customer preferences.

To start a successful fasteners business, it is important to have knowledge about different types of fasteners such as nuts, bolts, screws, rivets, and anchors. This includes understanding their various sizes, materials (such as stainless steel or brass), strengths (grade classifications), and applications in different industries.

Moreover, building strong relationships with suppliers is crucial for ensuring a steady supply chain and competitive pricing. Establishing connections with manufacturers or distributors can provide access to high-quality products at reasonable prices.

In addition to these considerations for starting a fasteners business successfully, profitability can be achieved by specializing in selling nuts and bolts specifically. By focusing on this niche segment of the market instead of offering a wide range of fastener products, businesses can streamline their operations and develop expertise that allows them to cater effectively to customer demands for nuts and bolts.

With a solid foundation in place for starting a fasteners business successfully through careful planning and market analysis, it is important to evaluate the profitability of selling nuts and bolts within this industry context.

2.Profitability of Selling Nuts and Bolts

The profitability of selling nuts and bolts can be determined by analyzing market demand, competition, and pricing strategies. Understanding the market demand is crucial for any business to succeed. Nuts and bolts are essential components used in various industries such as construction, automotive, aerospace, and manufacturing. By examining the current market trends and demands within these industries, one can identify potential opportunities for selling nuts and bolts.

Analyzing competition is equally important in determining profitability. Identifying key competitors, their pricing strategies, product offerings, and distribution channels allows businesses to position themselves effectively within the market. Additionally, conducting a thorough analysis of competitor strengths and weaknesses enables businesses to develop unique selling propositions that differentiate them from others.

Pricing strategy plays a significant role in the profitability of selling nuts and bolts. Appropriate pricing ensures competitiveness while maintaining profit margins. Factors such as cost of production, overheads, industry standards, customer affordability, and perceived value should be considered when developing pricing strategies.

Understanding market demand dynamics along with effective competition analysis and strategic pricing will contribute to maximizing profitability in the nuts and bolts business.

Industries using fasteners heavily rely on reliable suppliers who can provide quality products at competitive prices. Therefore, it is essential to establish strong relationships with these industries to ensure sustained success in the fastener business.

3.Industries Using Fasteners

Industries relying heavily on fasteners require stable partnerships with reliable suppliers who can deliver high-quality products at competitive prices. Fasteners are essential components used in various industries, including automotive, construction, aerospace, and manufacturing.

In the automotive sector, fasteners are crucial for assembling vehicles and ensuring their safety and performance. Construction companies rely on fasteners to securely join structural components such as beams and panels. Fasteners play a vital role in aerospace manufacturing by holding aircraft parts together under extreme conditions. The manufacturing industry also extensively uses fasteners for machinery assembly and maintenance.

These industries demand fastener suppliers who can meet their specific requirements in terms of quality, durability, size, and material composition. Moreover, these partnerships need to be built on trust and reliability to ensure timely delivery of fasteners as any delays or substandard products could lead to production disruptions or compromised safety standards.

Understanding the diverse needs of these industries paves the way for launching a nuts and bolts manufacturing business. By identifying gaps in the market or areas where existing suppliers fall short, entrepreneurs can establish themselves as reliable providers of high-quality fasteners tailored to meet industry-specific demands.

4.Launching a Nuts and Bolts Manufacturing Business

Identifying gaps in the market and areas where existing suppliers fall short can enable entrepreneurs to establish themselves as reliable providers of high-quality fasteners tailored to meet industry-specific demands. One area that presents a promising opportunity for entrepreneurs is the manufacturing of nuts and bolts. Nuts and bolts are essential components used in various industries such as automotive, construction, aerospace, and machinery manufacturing. However, many fastener suppliers struggle to meet the specific requirements of these industries, leading to inefficiencies and delays in production processes.

To set up a fasteners manufacturing unit successfully, several factors need consideration. First, it is crucial to conduct thorough market research to identify target industries and their specific needs. Understanding the demand patterns and customer preferences will help in determining the types of fasteners required for production.

Second, acquiring suitable machinery and equipment capable of producing high-quality fasteners efficiently is necessary. Additionally, establishing relationships with reliable raw material suppliers is vital to ensure a consistent supply chain.

5.Setting Up a Fasteners Manufacturing Unit

To establish a fasteners manufacturing unit, careful consideration of market research, suitable machinery and equipment, and reliable raw material suppliers is necessary. The following factors should be taken into account when setting up such a unit:

- Conducting Market Research: Before starting a fasteners manufacturing business, conducting thorough market research is crucial. This involves identifying the demand for various types of fasteners in the target market, understanding customer preferences, and analyzing competitors' products and pricing strategies.

- Acquiring Suitable Machinery and Equipment: Investing in high-quality machinery and equipment is essential for ensuring efficient production processes. This includes acquiring machines for cutting, shaping, threading, coating, and packaging fasteners. Additionally, considering automation options can help improve productivity and reduce labor costs.

- Establishing Reliable Raw Material Suppliers: To maintain consistent product quality, it is important to establish partnerships with reliable raw material suppliers who can provide high-grade materials such as steel or other alloys used for manufacturing fasteners.

- Implementing Quality Control Measures: Implementing stringent quality control measures throughout the production process is crucial to deliver reliable and durable fasteners to customers. This includes regular testing of raw materials, monitoring production parameters at each stage of manufacturing, and conducting final inspections before dispatching the finished products.

6.Exploring Precision Fasteners and Profitability

The profitability of precision fasteners can be explored by examining factors such as market demand, production efficiency, and cost management.

Market demand plays a crucial role in determining the profitability of precision fasteners. The demand for these specialized fasteners is directly influenced by industries such as automotive, aerospace, construction, and electronics. Understanding the specific requirements of these industries and staying up-to-date with technological advancements can help manufacturers target the right market segments and maximize their profits.

Production efficiency is another key factor that impacts the profitability of precision fasteners. Efficient manufacturing processes ensure timely delivery of high-quality products while minimizing resource wastage. Implementing lean manufacturing principles, investing in advanced machinery and automation technologies, and optimizing supply chain management are some strategies that can enhance production efficiency.

Cost management is essential for maximizing profitability in the precision fastener industry. Manufacturers need to carefully analyze their costs, including raw materials procurement, labor expenses, overheads, and transportation costs. Negotiating favorable contracts with suppliers, streamlining internal operations to reduce waste and improve productivity, implementing cost-saving measures like energy-efficient practices are all important steps in effective cost management.

Exploring screws and fasteners manufacturing in detail provides a deeper understanding of the intricacies involved in producing these essential components.

7.Screws and Fasteners Manufacturing in Detail

Screws and fasteners manufacturing involves a complex process that encompasses various stages. To ensure the production of high-quality screws and fasteners, manufacturers must carefully follow each step in the manufacturing process.

- Material selection: The choice of materials is crucial as it directly impacts the durability and performance of the screws and fasteners. Manufacturers consider factors such as strength, corrosion resistance, and cost when selecting materials.

- Design engineering: This stage involves designing the shape and dimensions of the screws and fasteners to meet specific requirements. Manufacturers utilize computer-aided design (CAD) software to create precise designs.

- Machining: Once the design is finalized, machines are used to cut or mold raw materials into the desired shape. This process requires precision to ensure accurate dimensions and smooth surfaces.

- Finishing: Screws and fasteners undergo various finishing processes such as heat treatment or coating to enhance their mechanical properties or protect against corrosion.

By meticulously following these steps in screws and fasteners manufacturing, manufacturers can produce reliable products that meet industry standards.

Sourcing reliable fastener suppliers is a critical aspect for businesses looking to establish themselves successfully in this field without compromising on quality or efficiency.

8.Sourcing Reliable Fastener Suppliers

Sourcing reliable suppliers of screws and fasteners is a crucial aspect in the manufacturing industry, as it ensures the procurement of high-quality materials for production. When considering potential suppliers, several factors need to be taken into account to guarantee a successful partnership.

Firstly, it is important to assess the supplier's reputation and track record. This can be done by conducting thorough research on their background, including their experience in the industry and any previous collaborations with reputable companies.

Additionally, evaluating the supplier's manufacturing capabilities and quality control processes is essential. This involves examining their production facilities, equipment, and adherence to industry standards such as ISO certifications.

Furthermore, assessing the supplier's financial stability is crucial to ensure that they have the resources necessary to meet your company's demands consistently.

Lastly, communication and responsiveness are key factors in selecting a reliable supplier. A prompt response time indicates a commitment to customer service and can help address any potential issues or concerns efficiently.

Overall, sourcing reliable suppliers requires careful evaluation of factors such as reputation, manufacturing capabilities, financial stability, and communication skills in order to secure high-quality materials for production purposes.

In conclusion, starting a fastener business can be a profitable venture due to the high demand for nuts, bolts, screws, and other fasteners in various industries. Setting up a manufacturing unit allows for greater control over production and quality. Precision fasteners offer higher profitability due to their specialized nature.

At Mikehardware , we will give you the best fastener quality and service, we will be your best cooperation supplier!

It is crucial to source reliable suppliers to ensure consistent product availability. One interesting statistic is that the global market for industrial fasteners is projected to reach $104 billion by 2027, highlighting the significant growth potential in this industry.

Contact us for a free quote of customizing fasteners!

Search Something You LIke

- Fastener Business

What Are Bolts Made Of?

Understanding Bolt Grades: A Comprehensive Guide for Custom Metal Hardware Manufacturers

Why CNC Machining Small Parts Is Essential for Modern Manufacturing

How to Choose the Right CNC Machine Parts Factory for Your Project

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Construction and Manufacturing

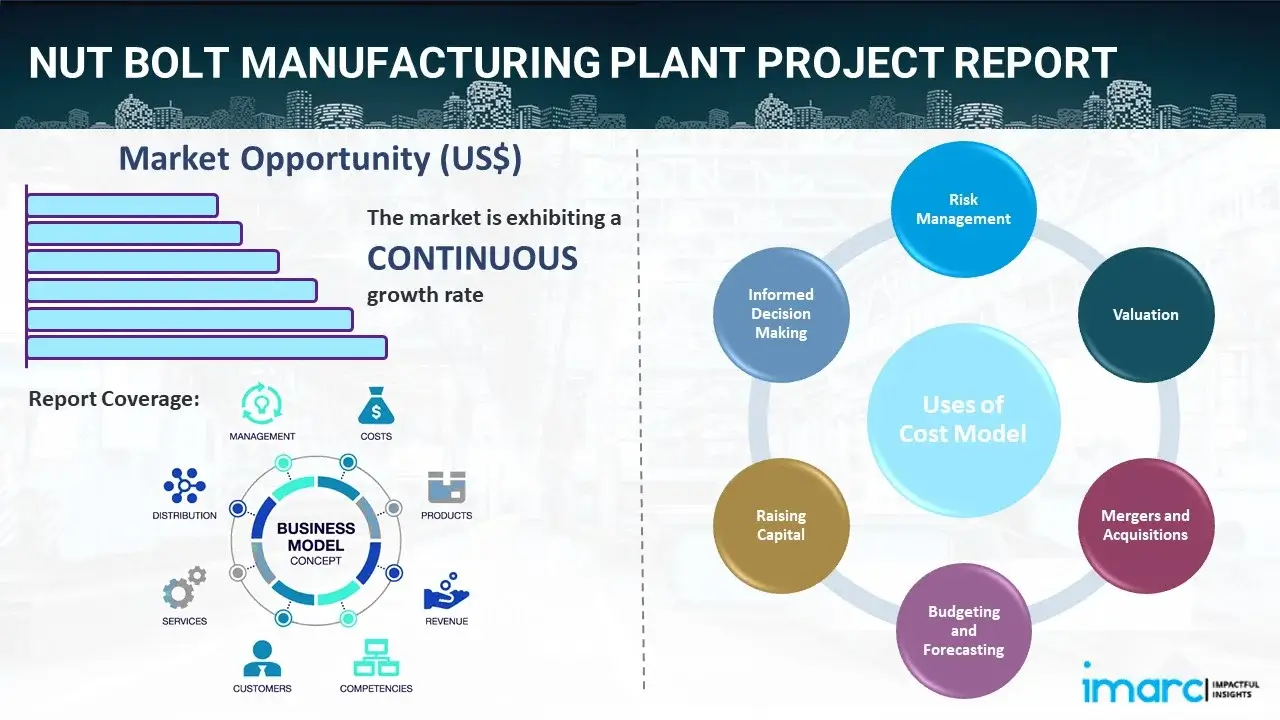

Nut Bolt Manufacturing Plant Project Report

Nut bolt manufacturing plant project report 2024: industry trends, plant setup, machinery, raw materials, investment opportunities, cost and revenue.

- Report Description

- Table of Contents

- Methodology

- Request Sample

Report Overview:

IMARC Group’s report titled “Nut Bolt Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a nut bolt manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

A nut bolt, also known as a fastener, is a type of mechanical component used to join two or more objects together. It consists of two main parts: a bolt and a nut. The bolt is a threaded rod with a head on one end, while the nut is a small, typically hexagonal-shaped piece with threads on the inside. To use a nut bolt, the bolt is inserted through a hole in one of the objects being joined, and the nut is threaded onto the end of the bolt. The bolt and nut are then tightened together, creating a secure connection between the two objects. Nut bolts come in a wide variety of sizes, shapes, and materials, depending on the specific application. They can be made from steel, stainless steel, brass, or other materials, and may be coated or plated for added durability. In addition to their use in construction and manufacturing, nut bolts are also commonly used in automotive and machinery applications, as well as in household items, such as furniture and appliances.

The increasing product demand in construction and infrastructure projects, including buildings, bridges, roads, and railways, represents a key factor driving the market growth across the globe. In line with this, the increasing industrialization and automation of manufacturing processes are contributing to the growth of the market. The market is also driven by the rising penetration of carbon and alloy bolts in several end-use industries, coupled with the widespread adoption of automated bolt-fastening systems. In addition to this, the expanding automotive industry, coupled with the introduction of electric and autonomous vehicles is facilitating the growth of the market. Apart from this, technological advancements in manufacturing processes, materials, and coatings are driving the market growth. Other factors, such as the increasing demand for automobiles around the world, along with the extensive product application in the aerospace industry, are creating a positive outlook for the market.

The report provides a techno-commercial roadmap for setting up a nut bolt manufacturing plant. The study covers all the requisite aspects that one needs to know while entering the nut bolt industry. This report is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the nut bolt industry.

The following aspects have been covered in the report on setting up a nut bolt manufacturing plant:

- Market Performance

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Outlook

The report provides insights into the landscape of the nut bolt industry at the global level. The report also provides a segment-wise and region-wise breakup of the global nut bolt industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of nut bolt, along with the industry profit margins.

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the process flow and various unit operations involved in a nut bolt manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, and expenditure for setting up a nut bolt manufacturing plant. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up a nut bolt manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a nut boltmanufacturing plant.

Report Coverage:

| Report Features | Details |

|---|---|

| Nut Bolt | |

| Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs Importance and Essentials, Layout, Factors Influencing Layout Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request) Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request) Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request) Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis Market Trends and Analysis, Market Segmentation, Market Breakup by Region, Price Trends, Competitive Landscape, Regulatory Landscape, Strategic Recommendations, Case Study of a Successful Venture | |

| US$ (Data can also be provided in the local currency) | |

| US$ 3450 US$ 4450 US$ 5450 | |

| The report can also be customized based on the requirement of the customer | |

| 10-12 Weeks | |

| PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report?

- How has the nut bolt market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global nut bolt market?

- What is the regional breakup of the global nut bolt market?

- What are the price trends of various feedstocks in the nut bolt industry?

- What is the structure of the nut bolt industry and who are the key players?

- What are the various unit operations involved in a nut bolt manufacturing plant?

- What is the total size of land required for setting up a nut bolt manufacturing plant?

- What is the layout of a nut bolt manufacturing plant?

- What are the machinery requirements for setting up a nut bolt manufacturing plant?

- What are the raw material requirements for setting up a nut bolt manufacturing plant?

- What are the packaging requirements for setting up a nut bolt manufacturing plant?

- What are the transportation requirements for setting up a nut bolt manufacturing plant?

- What are the utility requirements for setting up a nut bolt manufacturing plant?

- What are the human resource requirements for setting up a nut bolt manufacturing plant?

- What are the infrastructure costs for setting up a nut bolt manufacturing plant?

- What are the capital costs for setting up a nut bolt manufacturing plant?

- What are the operating costs for setting up a nut bolt manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for a nut bolt manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up a nut bolt manufacturing plant?

- What are the key success and risk factors in the nut bolt industry?

- What are the key regulatory procedures and requirements for setting up a nut bolt manufacturing plant?

- What are the key certifications required for setting up a nut bolt manufacturing plant?

Report Customization

While we have aimed to create an all-encompassing report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?