- Marketplaces

- Shopping Cart

- Advertising

- Content Marketing

- Contact Center

- Customer Experience

- Distribution Center

- Fulfillment

- Order Management

- Sector Spotlights

- Media & Marketing Events

- MCM Advisory Board

- Submit A Release

- Advertise with Us

Storage and Inventory Control Best Practices

Storage and inventory control processes include activities related to holding material and the processes of counting and transacting it as it moves through a fulfillment or distribution center.

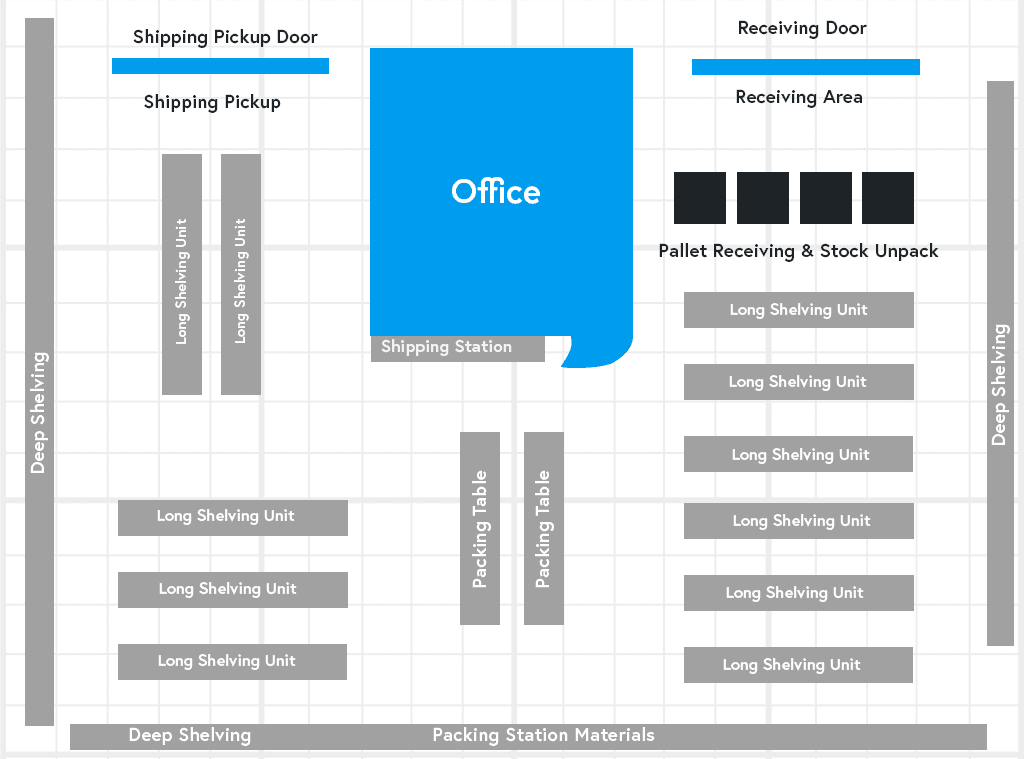

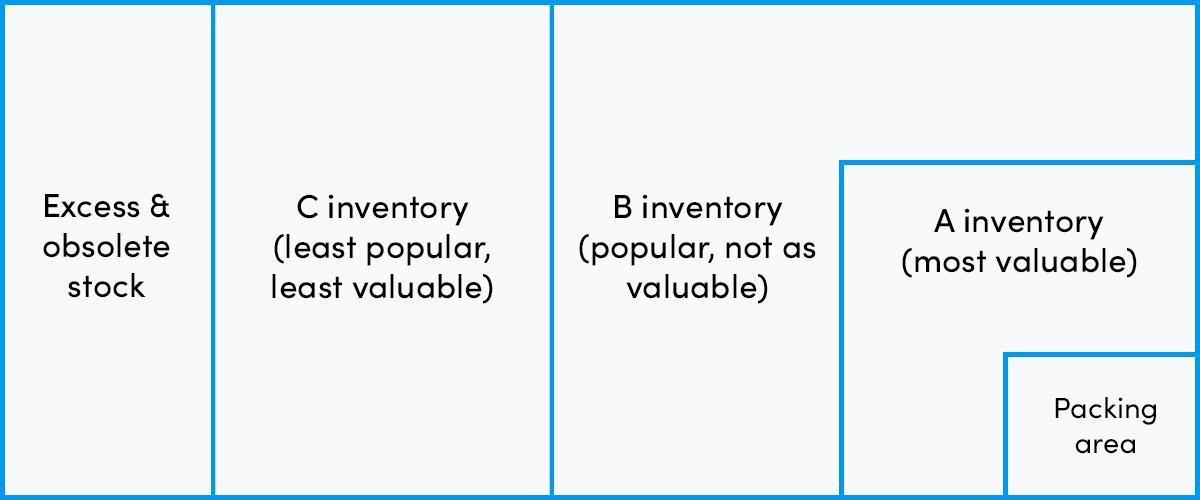

The layout of a facility supporting an adjoining manufacturing operation will have different requirements than one supporting distribution to stores or consumers. Some operations place emphasis on replenishment, others on picking and order fulfillment.

Regardless, best-practice companies have designed storage systems to meet the needs of the current and planned mix of storage types. This includes optimization of storage locations and layouts to fit product without the need to restack or re-palletize once received. The warehouse management system (WMS) will track storage location profiles and properly assign items to the optimal storage location. As a result, top performers have excellent cube-fill rates.

In addition to optimizing the cubic fill of storage locations for better inventory control, another best practice is to minimize travel time. If a particular SKU is in high demand, it should be placed closer to its next point of use. In this case, demand is based on the number of times the SKU is required, not on the number of units sold. The difficulty of retrieval should also be considered in terms of travel time. Higher-demand product should be placed on the most easily accessed storage space in a “hot zone,” typically at floor level for racking and between waist and shoulder level in pick racks.

Not all companies need to track product by lot or serial number, but if required, best-practice companies have integrated that capability into their DC or FC and and shipping processes, using the system of record to manage the lot and serial number data.

Most companies put a lot of effort into the initial facility layout. However, industry surveys will tell you that as many as half of companies don’t have an ongoing process to review their layouts. Reviewing how storage areas are configured and having processes in place to reconfigure them as product mix changes is considered a best practice and is critical to maintaining high levels of space utilization and efficiency. Making continuous small adjustments to racks, shelving or other storage equipment can greatly improve space utilization.

All warehouse software runs on data, so product and storage locations must be kept current and accurate. Best-practice companies maintain all information on a single system of record and keep it current and accurate. Product data should include all characteristics including cube, lot/serial number information and special requirements so it can be directed to special storage areas. Special storage areas may be used to segregate items with odor transfer or fire risk, or that require temperature control. High-value product might require caged or controlled-access storage.

Kate Vitasek is the founder of Supply Chain Visions

This article was originally published in 2007 and is frequently updated

Don't bother with copy and paste.

Get this complete sample business plan as a free text document.

Inventory Control Software Business Plan

Start your own inventory control software business plan

Royal's Software

Executive summary executive summary is a brief introduction to your business plan. it describes your business, the problem that it solves, your target market, and financial highlights.">.

Royal’s Software has embarked on an ambitious plan to create a new software product, Royal’s Inventory Basic–a scalable inventory software product. The new product is scheduled to be released in May and will be sold by Pursuit Solutions.

Pursuit Solutions, a $50 million company hardware integration reseller, will distribute Royal’s Inventory Basic to over 1,100 Valued Added Resellers (VARs). The product will sell for $2,499. Royal’s Software will receive $1,250 on each unit sold. It is projected that Pursuit Solutions will sell 250 units by month six. It is projected that Royal’s Software will gross $313,000 from sales the first year.

A critical component of software sales will be tech support and product modifications. Royal’s Software projects $63,200 in product modification by the end of six months.

In addition, Royal’s Software has entered into a business agreement with Pursuit Solutions and Johnson and Roe (CPA firm) to create a MAS 90 portable data collection interface that will be sold to accounting firms. The software product has been in development over the past ten months.

John Royal and Dan Whiteaker have been an integral part of the product development. MAS 90 is not a packaged product, rather it is bundled with software customization services ($2,000-$3,000) that will be performed by Royal’s Software. This software product will sell for $2,500.

Royal’s Software will receive 1/3 of gross sales ($833). It is projected that Royal’s Software will gross $500,500 by May of next year from product sales and customization services.

The two co-owners of Royal’s Software, John Royal and Dan Whiteaker, will each invest $50,000. In addition, the company will obtain a $100,000 short-term loan.

1.1 Objectives

The objectives of Royal’s Software are as follows:

- Establish the company as a leader in inventory software products.

- Increase sales by 20% each year.

- Develop one new inventory product per year.

1.2 Mission

The mission of Royal’s Software is to create inexpensive inventory software that will be scalable, so customer modification can be easily added.

1.3 Keys to Success

The ability to produce products on time and on budget, that meet the user’s needs and specifications.

Company Summary company overview ) is an overview of the most important points about your company—your history, management team, location, mission statement and legal structure.">

Royal’s Software creates scalable inventory software products that can be customized to meet customer’s needs. Royal’s Software is unique in that it sells a product that can be used in any inventory environment. The engineers can then add enhancement to the product that will tailor the product features to the customer’s specific needs.

2.1 Company Ownership

Royal’s Software is owned by John Royal and Dan Whiteaker. The company will be set up as a C Corporation. It is expected that this form of incorporation will allow room for growth and an exit strategy of selling the business in five to seven years.

- John Royal has ten years of experience as an application software developer for Rogue Wave Software. John was the Lead Developer for New Products for the last four years. He was the principal designer of Rogue Wave’s Ace Software Suite.

- Dan Whiteaker has seven years of programming experience with Rogue Wave Software. Dan assisted the Ace Software Suite Development Group. He lead the Customer Modifications Group for the past two years.

2.2 Start-up Summary

The following is the start-up summary for Royal’s Software. As is typical for software companies the largest portion of start-up funds will go towards product development.

Royal’s Software products and services include the following:

- Royal’s Inventory Basic.

- MAS 90 portable data collection interface.

- Custom Modification Royal’s Inventory Basic.

In addition to selling software, the company will provide extensive customization services to meet the unique needs of its business customers.

Market Analysis Summary how to do a market analysis for your business plan.">

Software products for inventory management are a $1 billion dollar industry. The lions share of the sales are with the largest companies with billions of dollars of inventory. This is where there is the greatest competition between inventory software products.

This category of the industry also faces competition from the enterprise resource planning software vendors. At the low end, with small and emerging businesses, there is very little competition.

Usually, the smaller businesses will spend no more than $5,000 on an inventory solution which will include software and hardware. Royal’s Software believes this a tremendous opportunity for a software product with a $2,500 price tag.

Another opportunity area is the growing demand for software interfaces that improve the portability of data. The interface improves the ability of businesses to move data between systems. In an age where new management products are introduced each year, a company’s ability to move its data quickly and efficiently is becoming essential to a successful business.

MAS 90 portable data collection interface is designed to be used by accounting firms to improve the portability of data the firms stores for customers.

4.1 Market Segmentation

Royal’s Software is targeting small- and medium-sized businesses. Specifically it will focus on these two target groups:

- Smaller businesses that will spend no more than $5,000 on an inventory solution, including software and hardware.

- Accounting firms demanding MAS 90 portable data collection interface.

Strategy and Implementation Summary

During the first two months of operation, the company will focus on completing and testing beta copies of Royal’s Inventory Basic and the MAS 90 portable data collection interface. Sales will begin in May and grow steadily for the next 10 months.

5.1 Sales Strategy

Royal’s Software will not do any direct selling, instead it will work closely with Pursuit Solutions’ VARs to sell and service Royal’s Inventory Basic. The two owners have existing relationships with a number of VARs through their existing positions, and since this product is unique in its price range, it is not expected that it will be difficult to find VARs to represent it.

MAS 90 customers will be developed by the CPA firm, Johnson and Roe. It is projected that the MAS 90 product will have over a 100 customers by June of 2003. A large number of small- to medium-sized businesses use MAS 90 in their dealings with Johnson and Roe, and it is expected that sales will be healthy through this channel.

5.1.1 Sales Forecast

The following is the sales forecast for the next three years.

Brought to you by

Create a professional business plan

Using ai and step-by-step instructions.

Secure funding

Validate ideas

Build a strategy

Personnel Plan

The current staff of Royal’s Software are the two co-owners of the company. The owners have been working on developing the product on their own time over the past year, are beta testing the product and now feel that they are only a couple of months away from having a final product. It is envisioned that Royal’s will need to ramp up significantly as sales take off and they are pulled away from product development and support in order to run the company. Three new hires are planned in March to meet the anticipated demands of software sales. The following positions will be filled:

- Application Engineer (1)

- Support Engineer (1)

- Technical Support Staff (1)

To keep fixed costs to a minium and to keep existing technical staff committed to the development of new products, much of the customization will be done by outside consultants. This expense is illustrated in the profit and loss table.

In addition, we will not have large sales and marketing costs, because VARS will take on this role on our behalf, and their large commissions shall reflect this.

Financial Plan investor-ready personnel plan .">

The following is the financial plan for Royal’s Software. The plan includes:

- Break-even point;

- Projected profit and loss;

- Projected cash flow;

- Projected balance sheet.

7.1 Break-even Analysis

The estimated monthly fixed cost and monthly break-even point are shown below.

7.2 Projected Profit and Loss

The following table and charts highlight the projected profit and loss for the next three years.

7.3 Projected Cash Flow

The following table and chart highlight the projected cash flow for the next three years.

7.4 Projected Balance Sheet

The following table highlights the projected balance sheet for the next three years.

7.5 Business Ratios

Industry profile ratios based on the Standard Industrial Classification (SIC) code 7372, Prepackaged Software, are shown for comparison.

The quickest way to turn a business idea into a business plan

Fill-in-the-blanks and automatic financials make it easy.

No thanks, I prefer writing 40-page documents.

Discover the world’s #1 plan building software

Inventory Control Guide: Definitive Plan for Business Owners

Inventory control is one of the key ways a business can keep its costs low. This in turn can lead to higher profit margins and increased sales.

If you're an inventory control manager or looking to become one, understanding how to control inventory is paramount. We'll walk you through all aspects of inventory control and management.

.jpg)

Let's start with a brief overview of what inventory control is.

Inventory Control Overview

Inventory control is the maintenance of a business's inventory level to fulfill orders and minimize costs. It involves managing inventory storage, movement, and maintenance. It also includes using data to make decisions that can increase the profit you make off this inventory.

The Purpose of Inventory Control

The primary purpose of inventory control is to protect inventory from damage or theft and to track inventory in the financial statements. Inventory control ensures a warehouse operates smoothly while keeping costs low and meeting customer demand. All stock must be recorded and this data can be used to make a variety of decisions.

The Application of Inventory Control Data

Using inventory control in your business requires investing time and money. This is done through either physical inventory counts or investing in a perpetual inventory management software. Both result in the accumulation of data regarding inventory levels and trends to plan for purchasing, controlling, and shipping goods.

The Value of Inventory Control

Inventory control is a vital part of any business' ability to make a profit. The major reasons it is valuable to control inventory are that it increases warehouse efficiency, ensures the accuracy of inventory data, can lower costs and increase revenue, and keeps your customers satisfied.

Without inventory control, a business's warehouse can quickly become a liability. If inventory is allowed to move about with no control, a manager risks running into skyrocketing costs and plummeting profits. This in turn will lead to the loss of their job and possibly the closure of the business.

Invest in Automated Inventory Control Systems

One of the best ways to take control of your business's inventory is to purchase a subscription to an inventory management software. This software tracks inventory levels, sales trends, and inventory cycles. Most of these programs can also be hooked to your POS system to provide a perpetual inventory count. This updates your inventory levels each time a sale is made. This feature is built into some of the best inventory control software and allows you to take a more hands-off role.

The other major component of inventory control is inventory management.

Inventory Management Process

Inventory management is the act of reducing inventory costs and optimizing the ability to meet demand. This is done using a variety of methods like reducing dead stock or calculating optimal reorder points.

This most important part of inventory management is that it requires a dedicated focus on inventory tracking.

Inventory management requires creating and following a simple set of processes to limit the chance of improperly managing your inventory.

There are eight steps in the inventory management process. These are: Receiving product, inspecting and sorting product, monitoring inventory levels, receiving orders, picking and shipping product, updating inventory levels, and placing reorders.

These eight steps can be done more efficiently with a properly managed inventory process flow. Each step can be optimized by tracking and reviewing each step. You can eliminate inventory shrinkage , discover flaws, and reallocate resources to any step that needs it to increase your profit and limit your costs.

How to Improve Inventory Management Process

There are many ways you can improve your inventory management and get the most out of your inventory. A few of the most common including communicating inventory needs to your suppliers, tracking product lead time to plan for reordering, hiring an inventory control manager, and using inventory management software.

The two major tools we recommend are the creation of an inventory management process map and the purchasing of an inventory management system.

Inventory Management Process Map

An inventory process map is a flowchart that shows every step in your inventory program. Though the eight steps are fairly standard, there are many variables that are specific to your businesses. By mapping out all steps and options, you can always be prepared for any changes in supply or demand.

Inventory Management System

An inventory management system is a program that tracks and manages all aspects of a company's inventory. This includes purchasing, shipping, tracking, storage, turnover, and reordering. This type of all-in-one inventory management software can be integrated into your POS system to provide a perpetual inventory count.

Now that you understand inventory control and management, let's dive deeper into the individual methods you'll need to know. We'll start with the most obvious, inventory tracking.

Inventory Tracking

Inventory tracking is one of the most important inventory control methods. Inventory levels influence all decisions you make and can quickly increase or decrease your revenue. They can be tracked manually or perpetually.

How to Track Inventory

The basic way to track inventory is to manually count your inventory every two weeks and compare the numbers versus sales. That's known as periodic inventory.

The other option is a perpetual inventory, where an inventory management app or software is integrated into your business's POS. This gives you access to live data at all times and lets you have more control over inventory tracking.

Inventory Tracking Best Practices

There's no single way to track inventory, but there are a few best practices that all businesses should adopt. The six main practices are to establish specific goals for your inventory, use ABC inventory analysis to bucket your products by value, keep safety stock, optimize inventory turnover ratio , increase packing efficiency, and adopt the FIFO method .

These practices can all be applied by manually tracking inventory or by using inventory tracking software.

How to Track Inventory Manually

To track inventory manually you need to physically take inventory at least twice. The first to establish baseline stock levels and again to determine usage. These two inventories are usually taken on the first and last days of the month.

Manual inventory tracking is much more labor-intensive than using tracking software, but can still make use of technology. This is by making use of a spreadsheet to track the data you collect. Still, inventory software offers a much less labor-intensive inventory tracking program.

Inventory Tracking Software

Inventory tracking software is a digital program or application that provides a perpetual inventory count. It is generally integrated into your POS and updates instantly every time an item is scanned as it's sold or shipped. It offers many long-term benefits to a business and eliminates the need for full, physical inventory counts every month.

Whether you use physical or perpetual inventory counts, the next important step is to perform inventory audits to ensure all information is correct.

Conducting an Inventory Audit

An inventory audit is when a business cross-checks its financial records against its inventory records. It is a vital part of inventory management and is done to ensure all records are accurate. These audits also uncover any discrepancies in inventory count or financial records.

How to Conduct Inventory Audit

Conducting an inventory audit requires pulling current data from a variety of sources. This may include inventory counts, sales records, shipping manifests, or other records.

Though there are many forms of inventory auditing, the workflow is mostly the same. You acquire at least two records that should reflect the same inventory numbers. Then check them against each other to discover if they do match. If not, flag the areas with issues and look into any problems that arise like missing inventory, damaged product, or inaccurate sales figures.

Inventory Auditing Procedures

Inventory audits can be completed by using a variety of auditing procedures. Some of the most common include performing a physical inventory count, performing a series of smaller cycle counts, or matching shipping invoices to financial records. In addition, a number of analyses may be conducted including an ABC inventory analysis, cutoff analysis, overhead analysis, finished goods inventory analysis, or freight cost analysis.

All of these procedures are intended to help you verify the information in your records is correct and to uncover any areas where you may be losing money. They are conducted according to strict inventory auditing standards.

Inventory Auditing Standards

Inventory auditing standards must be established by the business if they expect to achieve results. There are two rules that make inventory audits easier and more accurate.

First, audits need to be performed regularly and in the same method each time. If not, the data uncovered will not be particularly helpful as it could be incorrect. Second, inventory control needs to be practiced at all times, otherwise audits will become overwhelming and difficult for the team.

Now that you have a better grasp of the different ways you can audit your inventory, you can start working on limiting waste. One of the biggest issues uncovered during audits is dead stock.

What Is Dead Stock?

Dead stock is a form of surplus inventory that a business is unlikely to sell in the near future. It is a drain on warehouse resources and actively prevents a business's ability to increase its profits.

These products are not to be confused with buffer stock as they were not ordered with the intention of storing them for a long time. Dead stock continues to depreciate in value and may eventually expire or become obsolete and have to be written off as a loss.

Dead Stock Management

Dead stock inventory control consists of selling what you can and finding ways to minimize the expenses associated with dead stock. The key is that the inventory control manager needs to determine the causes of their dead stock.

Two major causes of dead stock are poorly managed lead times and reorder points. They can cause customers to cancel their orders and result in stock that was expected to be sold left sitting in the warehouse.

Inventory tracking is also a vital part of managing and eliminating issues with dead stock. It helps create inventory forecasts so you only order the correct amount of goods in the future and recognize sales trends and inventory cycles.

How to Get Rid of Dead Stock

Getting rid of dead stock can be very difficult, but it is important to limit losses. Some of the most common ways to offload dead stock is through kitting , limited-time sales, internal store transfers, selling to wholesalers, or returning the goods to the manufacturer.

Not all options are available to all businesses, so an inventory control manager needs to be flexible with dead stock. You can also find more customers for your products by listing them on an online marketplace .

Going forward you should also try to avoid running into issues with dead stock entirely. The first thing that needs to be controlled is product lead time.

Lead time is the amount of time that goes by from the start to finish of any given process. Lead time is one of the most important measures in inventory control.

Calculating, understanding, and acting on changes in lead time allows a business to prevent losses and fulfill orders quickly and efficiently. This is true for both retailers and manufacturers. It affects all businesses within a supply chain and can cause major issues if it gets out of control.

Lead Time in the Supply Chain

Total lead time is affected by every step within a supply chain. Production takes time, shipment takes time, and all other intermediary steps take time. As such, lead time in inventory management needs to be monitored and planned for regardless of business type.

Lead Time Is Bad

Long lead times can cause many problems that interfere with a business being able to fulfill orders.

For retailers, long lead time means a loss of sales and angry customers. For manufacturers, long lead time can cause production to halt entirely. It also leads to increased lead time for the retailers and strains relationships. Every additional day that goods are delayed, money is lost so you should always try to reduce it.

Lead Time Reduction

Lead time reduction can take a lot of time, but will help your business improve its sales and fulfillment capability. The most important factor when trying to reduce lead time is to look at your historical data.

There are a few ways you can use this information to reduce your lead times. These include switching suppliers, sharing data with your suppliers, and increasing reorder frequency.

Before you can try any of these methods, you need to know how to calculate your lead time.

Lead Time Formula

Calculating lead time requires a simple formula. There are two versions of the formula depending on if you're a manufacturer or a retailer.

For manufacturers, the lead time formula is:

Total Lead Time = Manufacturing Time + Procurement Time + Shipping Time

For retailers, the lead time formula is:

Total Lead Time = Procurement Time + Shipping Time

Using the inventory tracking tools and formulas above, you can keep your business operating smoothly and focus on increasing sales and revenue by calculating optimal reorder points.

Reorder Points

The reorder point is the level of standing inventory on-hand that alerts you to reorder. Essentially, when you hit this particular number, you should place an order to ensure you can continue to meet demand without any gaps.

Reorder point is not a stable number, but is flexible based on sales trends and the demand cycle of a given product. This means you need to have an understanding of each product's inventory levels and sales to optimize its reorder point. This is easily done using inventory management software that tracks everything you need to know about your inventory.

Reorder Point Formula

Uncovering the reorder point for a product can be done using a very simple formula.

Here's that formula:

Reorder Point = (Average Daily Usage x Average Lead Time) + Safety Stock

How to Calculate Reorder Point

To calculate the reorder point for a given product first requires that you determine a product's average daily sales, lead time, and amount of safety stock. Daily sales information can be pulled from your POS system if you have one. If not, you can look at inventory numbers and divide by the number of days between taking inventory. Safety stock can also be found in inventory counts.

Lead time can also be calculated for the product using the formula listed in the previous section. With these three numbers in hand, it's as simple as plugging them into the formula above to determine that product's reorder point.

Reorder Point Problems and Solutions

There are a number of issues that can hamper your ability to make the most informed reordering decisions. Here are just a few of the issues you may encounter.

Safety Stock and Reorder Point

Safety stock is additional stock you keep on hand in the event that demand suddenly increases. The issue here is that you may go through it more quickly than anticipated. This means you need to reorder earlier as well. Luckily, that is exactly why you keep safety stock on hand.

To combat any sudden shifts in demand and safety stock usage, track daily sales and recalculate your reorder points regularly.

Lead Time and Reorder Point

Lead time is the other major issue that may interfere with calculating your optimal reorder point. Unfortunately, you don't have much control over lead time as it is dependent on the supplier and shipper. However, this can be mitigated by keeping an adequate safety stock on hand. You should also calculate your reorder point daily to notice any changes in lead time as they occur.

Reorder point calculations are also a very important part of determining the correct amount of product to order. This is known as economic order quantity.

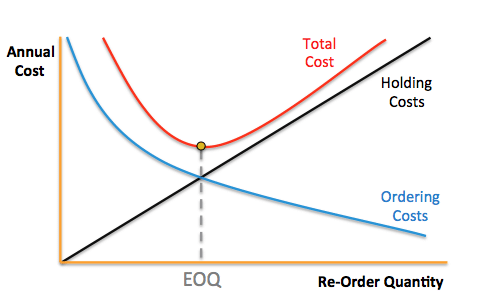

Economic Order Quantity

Economic order quantity is the ideal amount of product a company should purchase to minimize inventory costs. Essentially, it is the amount of product you need to order to meet demand without having to store any excess inventory.

Finding your optimal order quantity for a product is the goal of calculating its EOQ. However, it is very difficult to achieve as any slight variance in demand, cost, or price will throw the numbers off.

Economic Order Quantity Value

Managing economic order quantity can help avoid issues like excess stock or dead stock and keep avoidable losses to a minimum. It also helps establish goals for inventory KPIs, informs inventory forecasting decisions, and helps increase the company's sales and revenue. It is also a vital part of the just in time inventory model.

Advantages and Disadvantages of EOQ

Utilizing EOQ for your business has both advantages and disadvantages. On the plus side, economic order quantity allows you to minimize all costs associated with inventory and can easily be adapted to your business model. This will lead to higher profit margins and a streamlined workflow in the warehouse.

However, there are also a few drawbacks that you need to be aware of. Calculating EOQ can be difficult. You'll see the formula used for EOQ calculations below, and it's safe to say it isn't the easiest to use. The calculation is also based on assumptions, so your number will not be completely accurate if any of the numbers you use are not perfectly steady.

Economic Order Quantity Formula

Calculating the economic order quantity for a product can be done using a slightly complicated formula.

EOQ = √ (2 x Demand x Order Cost / Holding Cost)

Calculating the economic order quantity for your products can help you make the most out of your warehouse space, minimize costs, and increase revenue. It also allows you to make the most out of your inventory forecasting.

Inventory Forecasting

Inventory forecasting is used to predict future inventory levels needed to meet demand. This is done by combining historical data with future assumptions on demand cycles and sales trends.

Collecting data is the most important part of inventory forecasting. This requires a strong inventory management program. Sales trends, stock issues, and dead stock are just a few of the issues that can be uncovered by taking regular inventory.

How to Forecast Inventory

To forecast inventory levels, you must first take inventory at least twice. This can be done through physical inventories, cycle counts, or the use of a perpetual inventory program. Next, determine what products are selling well and if they are nearing their reorder point. This lets you predict future sales trends based on historical sales.

Each new inventory taken will provide further insight into inventory trends. You can use any shifts in sales or stock levels to make more informed forecasts.

Keys to Inventory Forecasting

There are many ways any business looking to forecast for inventory management and control can achieve their goals. There are three best practices you should use to get the most of your forecasting.

First, consistently track and record your inventory levels. If you don't, all of your forecasts will be based on faulty data and can lead to wasted money. Second, include all key players in decision-making. People not involved in inventory management are still affected by the decisions and have points of view that can be very helpful. Third, investing in inventory management software can pay dividends. Forecasting can be updated in real-time and you can minimize the chance of flawed forecasting.

Now that you know all of the major tools of inventory control, you're set to become a star inventory control manager.

Inventory Manager Salary and Job Description

Inventory control managers are in charge of all aspects of a business' inventory management and inventory control programs. They are a vital part of a company's management team and are responsible for warehouse operations and inventory tracking.

Inventory control managers are responsible for everything from inventory tracking to inventory auditing to inventory maintenance and more. They must also manage and direct warehouse personnel.

Inventory Control Manager Skills and Responsibilities

Due to the importance and varied nature of this role, inventory control managers must have a wide variety of skills. These skills include the ability to lead and direct others, solve complicated problems, use data in their decision-making, and have a sense of organization and attention to detail.

These skills are all used when meeting their responsibilities. These include managing and monitoring all inventory counts, performing inventory audits, forecasting inventory needs, tracking shipments, and training and leading warehouse staff.

Luckily, using the tools listed above, you can be prepared to become a talented inventory control manager.

Now, you're ready to take control of your inventory.

Get It Under Control

Whether you are an old hand at inventory control or you're new to the field, we can help. Just request a BlueCart demo, and we’ll get you on top of your inventory control. Warehouse inventory control is a vital part of all businesses and can help you spend less on inventory and increase profits.

The Best Inventory Storage Strategies For Small Businesses

Introduction.

Welcome to your ultimate guide to small businesses’ best inventory storage strategies. Effective inventory management is essential for any small business aiming to thrive in a competitive marketplace. Dealing with excess inventory levels can be daunting, but finding the proper storage solutions and maintaining an organized warehouse inventory can significantly streamline operations. Your storage unit choices, whether self-storage or shipping containers, play a crucial role in inventory control and fulfillment. Utilizing inventory management software or a comprehensive system can enhance inventory visibility, ensuring you keep your stock and goods in check. So, whether you’re a warehouse manager or a small business owner looking for efficient storage and fulfillment methods, this guide will equip you with tactics to optimize your storage space and manage inventory costs effectively. Let’s dive deeper into these inventory storage solutions to ensure your business is always ready to meet customer demand.

What You’ll Learn In This Blog

Welcome to this comprehensive guide on small businesses’ best inventory management strategies. We understand that keeping a check on inventory levels can be overwhelming. That’s where effective inventory management plays a pivotal role. Every aspect holds significant importance in the supply chain, from deciding on the proper storage unit to managing excess inventory. This blog aims to help warehouse managers and small businesses navigate the complex realm of inventory control. You’ll learn how to optimize storage space, handle stock, manage goods, and get a grip on economic order quantity for smooth fulfillment. We will also touch upon the role of inventory management software and highlight how a well-executed inventory management system can enhance inventory visibility. It’s all about adopting the proper inventory storage solutions to keep your inventory count in check and meet customer demand efficiently.

What Is Inventory Storage?

In simple terms, inventory storage refers to housing your products before they are sold. It’s the mechanism businesses use to organize and store their goods ready for sale. How you hold your inventory plays a crucial role in your fulfillment process and can significantly impact your business’s efficiency and profitability. Optimal storage solutions enable easy navigation, streamline access to stored goods, and ensure that products are kept in suitable conditions to minimize damage and waste. Whether you’re using a traditional warehouse, a self-storage unit, or a high-tech fulfillment center, your inventory storage practices directly affect your inventory control and management. Efficient inventory storage is about more than finding space for your products. It’s about organizing your inventory to enhance visibility, optimize space utilization, speed up picking and packing processes, and ultimately lead to smooth and effective fulfillment.

Why Is Inventory Storage Important?

It keeps merchandise organized.

Proper inventory storage is the backbone of successful small businesses, significantly influencing their fulfillment process, efficiency, and profitability. This guide is a comprehensive tool to assist small companies and warehouse managers navigate the intricate world of inventory management. You’ll learn to select a suitable storage unit, manage excess inventory, optimize storage space, and leverage inventory management software for increased visibility and control. Through effective storage strategies and solutions, you can ensure your goods are always ready to meet customer demand, thereby enhancing your business’s efficiency and profitability. Let’s delve into the importance of inventory storage and how it keeps your merchandise organized.

It Can Help Minimize Theft

Inventory storage is a dynamic aspect of a successful small business, influencing efficiency, profitability, and fulfillment processes. This guide aims to equip small businesses and warehouse managers with efficient inventory storage strategies, from choosing the appropriate storage units to managing excess inventory and optimizing space utilization. Inventory management software and systems can enhance inventory visibility, ensuring effective stock control. This piece will delve into the significance of inventory storage, mainly how it aids in organizing merchandise and minimizing theft. The ultimate objective is to ensure that your business consistently meets customer demand, optimizes space, and keeps inventory costs in check. Let’s explore the importance of inventory storage and its impact on small business operations.

Inventory Storage Is Essential For Accurate Stock Counts

Accurate stock counts lie at the heart of effective inventory management. It is essential for gauging the state of your inventory, understanding your storage capacity, and identifying potential discrepancies before they escalate into costly issues. A well-organized inventory storage system enables accurate stock counting, ensuring your business is always prepared to meet customer demand. Inventory management software and procedures can be crucial by providing real-time visibility into your stock levels and facilitating efficient inventory control. Let’s delve into why inventory storage is a key component in maintaining accurate stock counts and how it can optimize your business operations.

Inventory storage is more than just a place to house your business’s stock. It’s a crucial component of your logistics and order fulfillment process, impacting your efficiency, profitability, and overall business success. This guide’ll delve into everything you need about adequate inventory storage. From optimizing your physical storage space and managing excess inventory to leveraging inventory management software for real-time stock visibility, we’ll provide you with the best strategies to streamline your storage practices. By following these strategies, you can organize your goods, minimize theft, maintain accurate stock counts, and efficiently meet customer demand. This guide is your pathway to mastering inventory storage and taking your small business to the next level.

It Can Help You Track What Sells And What Doesn’t

Adequate inventory storage is a critical strategic component in organizing goods and tracking what sells and what doesn’t. It offers insightful data into consumer buying behavior, helping businesses streamline their inventory and focus on products that have a higher turnover rate. This, in turn, optimizes storage space and reduces carrying costs associated with slow-moving items. Software solutions can further enhance tracking, providing real-time data on stock levels, sales trends, and inventory turnover. This allows businesses to anticipate demand, adjust their stock levels accordingly, and make informed product ordering and storage decisions. Consequently, efficient inventory storage strategies contribute significantly to a small business’s profitability and success.

Inventory Storage Contributes To A Positive Customer Experience

Inventory storage significantly contributes to a positive customer experience, a paramount factor in today’s competitive retail landscape. Efficient storage strategies guarantee that popular products are always in stock, ensuring that customer orders can be fulfilled promptly and accurately. This not only leads to customer satisfaction but also fosters loyalty, as customers are more likely to return if they have a seamless shopping experience. Moreover, inventory storage offers insights into buying behaviors, helping businesses cater to their customers’ needs more effectively. Inventory management software plays a crucial role in this process, providing real-time stock levels and sales trends, allowing businesses to anticipate customer demand and adjust their stock levels accordingly. In essence, effective inventory storage is vital for enhancing customer experience and fostering business growth.

Where Is Inventory Typically Stored?

How to store inventory at home.

Storing inventory at home is a feasible solution for many small businesses, especially those operating on a tight budget or dealing with a limited number of products. To effectively store inventory at home, you need to focus on organization. Using areas such as spare rooms, basements, or garages can provide ample space for your inventory. You can employ shelving units, bins, or boxes to keep your products organized and easily accessible. It’s crucial to label everything clearly and maintain an organized system to ensure quick and accurate order fulfillment. Implementing an inventory management software can further simplify the process, providing real-time updates on stock levels and helping to avoid overstocking or understocking. Remember, while storing inventory at home can save costs, it’s important to ensure the space is secure, clean, and suitable for your products to maintain their quality.

How To Store Inventory In Your Back Office

Storing inventory in your back office can be a practical choice for businesses with modest inventory needs. This choice requires a systematic approach to avoid clutter and ensure efficient fulfillment. You can use shelves, bins, and cupboards to keep your items organized. Labeling items and having a consistent system in place is critical for easy navigation and quick order fulfillment. Consider investing in an inventory management system or software to track stock levels and sales trends. This will aid in preventing overstocking or running out of stock. Ensure your back office is clean, secure, and well-ventilated to maintain the quality of your products.

How To Store Inventory On Your Shop Floor

Storing inventory directly on your shop floor can be an efficient strategy, particularly for retail businesses. The key to successful on-floor inventory storage is creating a balanced display that is both aesthetically pleasing and functional. Use fixtures and shelving units that cater to your product sizes and shapes, optimizing space and ensuring easy access to items. Always keep high-demand products within easy reach to facilitate quick sales and restocking. Implement an inventory management system to monitor stock levels directly from the shop floor, helping to prevent overstocking or stockouts. Maintaining a clean, safe, and organized shop floor is crucial not just for inventory management, but also for providing a positive customer experience.

How To Store Inventory In A Warehouse

Storing inventory in a warehouse is a common strategy for businesses with large volumes of merchandise. Warehouses offer ample space and are designed to accommodate different types of goods with varying storage requirements. Effective warehouse storage starts with a well-organized layout to facilitate easy access to items, optimize space utilization, and streamline the picking and packing processes. Use pallet racking systems, stacking shelves, and bins to keep your products well-organized. Incorporate a labeling system for easy navigation and quicker order fulfillment. Equally critical is the use of inventory management software for real-time tracking of stock levels, managing excess inventory, and preventing stockouts or overstocking. Ensure the warehouse is clean, secure, and well-ventilated to maintain the quality of your products. Ultimately, efficient warehouse practices lead to improved fulfillment processes, customer satisfaction, and overall business success.

What About Dropshipping?

Dropshipping is a distinct inventory management method that eliminates the need for businesses to maintain a physical inventory. Instead, it allows them to purchase products from a third party, typically a wholesaler or manufacturer, who then ships the goods directly to the customer. This model can be a game-changer for small businesses, enabling them to sell a vast variety of goods without having to worry about inventory or storage costs.

Understanding The Dropshipping Model

In the dropshipping model, the retailer acts as a middleman between the supplier and the customer. When a customer places an order, the retailer forwards the order details to the dropship supplier, who handles the inventory control and order fulfillment. This model minimizes the risk associated with carrying excess inventory and reduces the operational costs related to storage and shipping.

Advantages Of Dropshipping

- Low overhead : Dropshipping eliminates the need for a storage unit or warehouse space, reducing inventory costs.

- Wide range of goods : Small businesses with limited resources can offer a variety of products due to reduced inventory costs.

- Convenience and flexibility : Retailers can easily add or remove products from their inventory, adapting to market trends and customer demand.

Dropshipping And Inventory Visibility

While dropshipping can simplify the inventory management process, it also poses some challenges. One of these is maintaining inventory visibility. With goods stored and shipped by a third party, maintaining an accurate inventory count can be difficult. Investing in a robust inventory management system can mitigate this issue, allowing retailers to keep track of stock levels and sales in real-time, thus enhancing inventory control.

The Impact Of Dropshipping On Fulfillment

The dropshipping model can also have significant implications for order fulfillment. Since the retailer does not physically handle the goods, the control over order fulfillment falls to the supplier. This can lead to potential issues with product quality, shipping delays, or incorrect shipments. Retailers must put in place strict supplier agreements to ensure the smooth execution of the fulfillment process.

Incorporating Dropshipping Into Your Business Model

When deciding whether to incorporate dropshipping into your business model, it’s essential to consider your business’s specific needs and capabilities. If you’re a small business owner dealing with limited resources, dropshipping can provide an efficient and cost-effective solution. Remember, though, that successful dropshipping relies heavily on finding reliable suppliers, maintaining good communication, and leveraging a robust inventory management software to maintain inventory visibility and control.

In conclusion, dropshipping offers a unique approach to inventory management. While it does present its own set of challenges, with the right strategies and tools in place, it can be an effective solution for businesses looking to expand their offerings without the added burden of inventory and storage management.

Should You Store Traveling Inventory Separately From The Rest Of Your Stock?

Inventory storage is vital for small businesses, influencing their efficiency, fulfillment process, and profitability. It’s not only about finding space for goods, but also organizing inventory in a manner that enhances visibility, optimizes space utilization, and expedites picking and packing. A well-organized inventory storage system allows accurate stock counts, and inventory management software keeps track of real-time stock levels. Aided by such systems, businesses can anticipate customer demand and adjust their inventory accordingly. Effective inventory storage strategies yield insights into customer buying patterns, helping businesses focus on fast-selling products. Such strategies are foundational to a positive customer experience, ensuring prompt and precise order fulfillment. Inventory can be stored at home, back offices, the shop floor, or warehouses, each requiring a systematic approach for organization and easy access to goods. Ultimately, a well-planned inventory storage strategy contributes significantly to a small business’s success.

Best Practices

1. free up floor space.

A key component for small businesses’ success lies in effective inventory storage. It significantly influences efficiency, fulfillment processes, and profitability. It’s not merely about having a place for goods but entails strategic organization to enhance visibility, optimize space, expedite order fulfillment, and maintain accurate stock counts. With the aid of inventory management software, businesses can keep track of real-time stock levels and anticipate customer demand. Moreover, efficient inventory storage strategies provide insights into customer buying patterns, allowing businesses to focus on fast-selling products and contribute to a better customer experience. Whether storing at home, back office, shop floor, or warehouse, each choice requires a systematic and organized approach for the smooth functioning of operations. Ultimately, robust inventory storage strategies significantly underpin a small business’s success.

2. Store By Season

For small businesses, successful inventory storage isn’t just about finding space for goods; it hinges on strategic organization. This boosts visibility, optimizes space, speeds up order fulfillment, and ensures accurate stock counts. With an effective inventory management system, businesses can track real-time stock levels, anticipate customer demand, and gain insight into customer buying behaviors. This, in turn, allows businesses to focus on fast-selling items and enhance customer experience. Inventory can be stored at various locations – home, back office, shop floor, or warehouse, each needing a systematic and organized approach for smooth operations. Ultimately, efficient inventory storage is a critical success factor for small businesses, influencing efficiency, fulfillment processes, and profitability.

3. Get The Right Software

In the small business sphere, inventory storage is a critical aspect influencing success. It plays a significant role in managing efficiency, order fulfillment, and profitability. The key lies not just in securing space for goods but in strategic organization, which enhances visibility, space optimization, and accelerates order fulfillment while ensuring accurate stock counts. Employing inventory management software enables real-time stock level tracking, anticipating customer demand, and gaining insights into customer buying patterns, thus enhancing customer experience. Whether stored at home, in the back office, on the shop floor, or warehouse, each venue requires a systematic approach to ensure smooth operations. In essence, effective inventory storage is pivotal for small businesses, laying the groundwork for efficiency, profitability, and a positive customer experience.

What Are The Best Methods For Organizing And Tracking Inventory In Storage?

Effective inventory storage strategies are vital for small businesses, significantly impacting efficiency, fulfillment processes, and profitability. These strategies encompass more than just finding room for goods – they entail systematic organization to enhance visibility, optimize space, expedite order fulfillment, and ensure accurate stock counts. Utilizing inventory management software can offer real-time stock level tracking and customer demand insights, enabling businesses to cater to customer buying patterns. Depending on the volume and type of inventory, it can be stored at various locations such as homes, back offices, shop floors, or warehouses. Each location requires a systematic and organized approach for smooth operations. Essentially, robust inventory storage strategies not only contribute to efficiency and profitability but also foster a positive customer experience.

Storing Inventory With Growth In Mind

Ensuring efficient inventory storage is a cornerstone for small business success, impacting efficiency, order fulfillment, and profitability. Key strategies involve careful organization and the use of inventory management software for real-time stock level tracking and customer demand anticipation. These systems aid in understanding customer buying behaviors, which in turn, improve customer experience. Inventory can be stored in various locations, including homes, back offices, shop floors, or warehouses, each requiring a systematic approach for smooth operations. Ultimately, proper inventory storage is not just about having space but is about strategic organization that maximizes visibility, optimizes space, and ensures efficient order fulfillment. This, combined with the insights from inventory management software, significantly contributes to business growth and customer satisfaction.

Conclusion

In conclusion, efficient inventory storage is paramount to the success of small businesses. It’s more than just finding a place to store goods. Strategic organization enhances visibility, optimizes space, increases order fulfillment speed, and ensures accurate stock counts. By leveraging inventory management software, businesses can track real-time stock levels, anticipate customer demand, and gain valuable insights into customer buying patterns, leading to better customer experiences. Regardless of where inventory is stored – be it at home, in the back office, on the shop floor, or in a warehouse, each requires a systematic and organized approach to ensure smooth operations. Overall, a robust inventory storage strategy is a significant contributor to business growth and customer satisfaction.

Now that you have a comprehensive understanding of the best inventory storage strategies for small businesses, it’s time to put this knowledge into action. Experience firsthand the benefits of streamlined inventory management with Orderific. Book a demo today and begin your journey towards improved efficiency, profitability, and customer satisfaction.

Why is efficient inventory storage important?

Efficient inventory storage optimizes space, improves order fulfillment, and boosts profitability.

What are some common inventory storage methods?

Common inventory storage methods include storing at home, in the back office, on the shop floor, and in a warehouse.

How do I determine the right storage solution for my inventory?

The right storage solution depends on your inventory volume, storage space, and operational needs.

What’s the role of inventory management software in storage?

Inventory management software aids in tracking stock levels, forecasting demand, and providing insights into customer buying patterns.

How can I optimize limited storage space?

Optimize limited storage space by utilizing vertical space, employing efficient shelving systems, and keeping your inventory well-organized.

Introduction In the dynamic realm of event planning, professionals constantly seek new ways to streamline their operations with software customization Read more

Introduction The event registration process is a critical component in event planning. It shapes the initial experience of future attendees Read more

Introduction Event management software can be a game-changer for event professionals seeking optimized outcomes. This robust tool streamlines event planning, Read more

Introduction Every detail counts in orchestrating a successful event in the bustling sphere of event planning. Amidst the complexities, event Read more

You might also like

Fight against the restaurant worker shortage with tech, a guide to michigan’s minimum wage: fair compensation unveiled, pof login: easy steps to connect, microbrewery 101: different brewery types explained, what’s the recipe for rolled ice cream to make at home, enhance your workstation: the perfect iphone stand for your desk, get a free demo now, turn your food business into a smart restaurant for free with orderific pay at the table software.

- Inventory Management

- Order Management

- Warehouse Management

- Shipping Management

- Picking & Packing

- Omnichannel

- Wave Picking

- Realtime Inventory

- Store Fulfillment

- Consumer Goods

- Food & Beverage

A Comprehensive Guide to Inventory Control Management: Benefits, Challenges, and Best Practices

What is the Inventory Control Process?

Inventory control is the process of managing and tracking the inventory levels, orders, sales, and deliveries of a business. It can involve manual or automated processes to ensure that the right amount of stock is available at all times, while also keeping costs low by preventing over-ordering or under-ordering. The goal of effective inventory control is to maintain cost-effective levels of stock, avoid stock shortages or surpluses, and maximize customer satisfaction with on-time orders. Automated inventory control systems are increasingly used for their ability to track stock in real time, plan for future needs based on historical data, and quickly generate reports.

Types of Inventory Control Systems

Inventory control systems are a set of technologies, processes, and procedures used to monitor and manage the ordering, storage, and use of materials within an organization or business. They help companies keep track of their inventory in real-time, make sure it is available when needed, and also help monitor inventory cost and quality control.

There are three main types of inventory control systems: manual record keeping, automated inventory management systems, and enterprise resource planning (ERP) software. Manual record keeping involves tracking inventory by hand-written records or spreadsheets while automated systems use computer hardware and software to track stock levels. ERP software integrates all aspects of a company’s operations into a single system that allows for the automation of many processes such as order management, production scheduling, supply chain management, and more.

Benefits of Inventory Control Systems

Improved accuracy and productivity .

A proper inventory control system helps improve accuracy and productivity by managing and tracking the movement of goods and products. It accurately records product information, such as quantity, availability, location, and price, allowing for better forecasting of inventory needs. By automating processes like stock counting and ordering, it eliminates manual errors and reduces the time needed to manage inventory. This ultimately leads to more accurate record-keeping, improved efficiency in operations, and increased cost savings.

Reduce Costs and Overstocking/Understocking Issues

An inventory control system helps reduce costs and overstocking/understocking issues by allowing for more accurate tracking and forecasting of inventory needs. These control techniques can help a business achieve its goal of holding the least amount of inventory necessary to meet customer demand while increasing inventory turnover. Automated processes (stock counting, ordering, invoicing, etc.) help to optimize inventory levels and eliminate manual errors, while regular reporting provides visibility into the performance of current stock levels. This information can be used to optimize purchasing decisions, reducing the chance of costly excess inventory or understocking issues. Additionally, inventory control systems can help identify waste and inefficiencies in operations.

Data and Supply Chain Visibility with Real-Time Updates & Tracking Capabilities

An inventory control system increases data visibility with real-time updates and tracking capabilities. Data is automatically updated when goods are received and shipped, providing an accurate overview of current stock levels and inventory availability. Additionally, tracking capabilities enable the monitoring of product movements across multiple locations in real time. This provides greater transparency into the performance of the supply chain, allowing for faster decision-making and improved customer service.

Increased Customer Satisfaction & Better Business Decisions

An effective inventory control system helps achieve customer satisfaction by having the right products available in the right quantity at the right time. Good stock control also helps businesses make better decisions about production, when to purchase inventory, and sales, and helps ensure they don't carry too much inventory relative to customer demand. Inventory control is the process of managing the availability, storage, and use of products in a business. A periodic inventory system requires a physical count of stock at certain intervals. A perpetual inventory system keeps a continuous record of stock on hand. Inventory control requires careful management of ordering and stocking levels, accurate tracking of stock, and efficient use of resources.

More Efficient Warehouse Operations with Optimized Inventory Control Methods

An inventory control system makes warehouse operations more efficient by automating processes such as stock counting, ordering, and invoicing. It also provides visibility into current stock levels and product movements across multiple locations in real time. This helps to ensure that the right products are in the right place at the right time, allowing for faster order fulfillment and improved customer service. Additionally, it eliminates manual errors, eliminates redundant tasks and reduces wasted effort, ultimately leading to a more efficient warehouse operation.

Major Inventory Control Challenges

Manual processes can wreak havoc with your inventory.

Man ual processes for inventory control can be extremely difficult and time - consuming . Without automation , it is difficult to keep track of all the changes in inventory data , such as stock levels , ordering , and pricing . Manual processes are prone to errors and can be difficult to scale as inventory needs increase . In addition , without real - time updates , manual processes are often not as efficient as automated solutions , making it difficult to ensure accurate inventory control .

Inventory Control is Important, TOO Important to Rely on Outdated Technology

In addition to inefficient and error-prone manual processes, older systems may lack the capabilities to track items in real - time . T he use of outdated technology can also result in slow response times , difficulty accessing data , and siloed information . To overcome these challenges , organizations must invest in modern and efficient technologies that enable them to accurately track and manage inventory , while also providing visibility into their supply chains .

Communication Breakdowns are Significant Challenges of Inventory Control

Without accurate information and efficient communication, it can be difficult to know when to restock or replenish items, leading to inventory shortages or overstock. Poor communication can also lead to incorrect orders, delayed shipments, and other issues that can disrupt the inventory process. To avoid this, businesses must ensure that communication between departments is clear, concise, and up-to-date, to effectively manage and maintain inventory control.

Disorganized Systems Make Inventory Control Impossible to Fully Achieve

Dis organized systems can be a major challenge to maintaining inventory control . With no clear structure in place , it can be difficult to track inventory levels, locations, and to know when items need to be re - ordered . A lack of accurate tracking can lead to over st ocking or stock - outs , both of which can create costly problems for businesses . To ensure proper inventory control , it ’ s important to create and maintain an organized system that can easily be managed and updated .

Different Types Of Inventory Control Software Solutions

Warehouse inventory control software solutions.

Warehouse inventory management software solutions provide businesses with the tools they need to effectively manage their inventory. These solutions allow businesses to track stock levels, optimize order fulfillment, automate replenishment, and analyze data for insights into inventory performance. Warehouse inventory control software helps businesses save time and money by streamlining the inventory process.

Enterprise Resource Planning (ERP) Software Solutions

Enterprise resource planning (ERP) software solutions provide businesses with the tools they need to manage their operations effectively. These solutions allow companies to integrate and streamline their processes, from accounting and finance to human resources and operations. ERP software helps businesses save time and money by simplifying the management of their operations.

Cloud-Based Warehouse Management Systems (WMS)

Cloud-based warehouse management systems (WMS) provide businesses with the tools they need to effectively manage their warehouse operations. These solutions allow businesses to automate and optimize their processes, from inventory control to order fulfillment. Cloud-based WMS helps businesses save time and money by streamlining their warehouse operations.

Radio Frequency Identification (RFID) Technology

Radio frequency identification (RFID) technology is a cost-effective solution for businesses to track their inventory in real time. RFID technology uses radio waves to transmit data from tags attached to items, helping businesses automate the identification, tracking, and management of their inventory. By automating their processes, businesses can save time and money with RFID technology.

Barcode Scanning Technologies

Barcode scanning technologies are an efficient and cost-effective solution for businesses to track and manage their inventory. This technology uses scanners to read barcodes on items, helping businesses automate the identification, tracking, and management of their inventory. Barcode scanning technologies help businesses save time and money by streamlining their processes.

Automated Data Collection (ADC)

Automated data collection (ADC) is a technology used by businesses to collect data in real time from various sources. ADC technology uses sensors to detect and collect data from items, helping businesses automate the identification, tracking, and management of their inventory. ADC helps businesses save time and money by streamlining their processes.

Automatic Identification and Data Capture (AIDC)

Automatic identification and data capture (AIDC) is a technology used by businesses to automate the identification, tracking, and management of their inventory. AIDC technology uses scanners, barcodes, and RFID tags to collect data from items, helping businesses save time and money by streamlining their processes.

Mobile Devices/Mobile Computing Technology

Mobile devices/mobile computing technology is a cost-effective solution for businesses to manage their operations on the go. This technology uses smartphones, tablets, and other devices to access data and applications from anywhere, helping businesses automate their processes. Mobile devices/mobile computing technology helps businesses save time and money by streamlining their operations.

Steps for Implementing an Inventory Control System For Your Business

Analyze existing processes to identify areas for improvement or automation.

A business should analyze existing processes to identify areas for improvement or automation. This can be done by collecting and analyzing data to identify areas where processes can be simplified or automated, determining which tasks can be outsourced or automated, and evaluating how technology can be used to improve efficiency. Doing so can help the business reduce costs, improve customer service, and increase profitability.

Select a System to Control Inventory that Suits Your Needs

A business should select the right type of inventory control system that suits its needs. This can be done by assessing the business’s current inventory needs and processes, researching different inventory control systems, and comparing features and costs to determine which system best meets the business’s needs. This will help the business stay organized and ensure that the right amount of inventory is available at the right time.

Train Employees in Using the New Inventory Control Management System

To train employees how to use a new inventory software control system, the business should provide clear instructions and demonstrations, create a user manual and other training materials, and offer support and guidance as needed. It is also important to give employees time to practice using the system and to provide feedback so that any issues can be addressed. Doing so will help the employees gain confidence in the system and ensure successful implementation.

Monitoring Usage and Performance of the New System is a Critical Control Technique

To monitor the usage and performance of an inventory control system, the business should regularly review reports and data, track user activity, and assess key performance metrics. This will help the business identify possible issues and areas for improvement, and ensure the system is being used effectively. Doing so will help the business optimize the system and maximize its benefits.

Adjust Settings as Needed

To adjust settings as needed, the business should review user feedback and data, assess the impact of any changes, and make necessary adjustments. This will help the business ensure that the settings are optimized for the business’s needs and that the system is running as efficiently as possible. Doing so will help the business get the most out of its inventory control system.

Explore Options for Expanding the Use of Your Current System

To explore options for expanding the use of your current system, the business should research new features and capabilities, determine if they are compatible with the existing system, and assess the cost and potential benefits of implementing them. Doing so will help the business get the most out of its current system and ensure that it meets its evolving needs.

Advantages Of Using An Inventory Control Management System For Small Businesses

Process of inventory control saves money with improved accuracy & fewer errors.

An inventory control system helps to improve accuracy and reduce errors by tracking the movement of goods and materials, monitoring stock levels, and providing real-time visibility into inventory on hand. It also helps to streamline processes and optimize workflow, resulting in more efficient stock replenishment and better inventory management. Additionally, it can generate automatic alerts for low stock levels and provide reporting capabilities to help businesses better manage their inventory and maximize profits.

Enjoy Easier Tracking and Auditing Capabilities

Control over your inventory enables easier tracking and auditing capabilities by providing real-time updates on stock levels, inbound and outbound shipments, and stock location. It also records and stores detailed information, such as product serial numbers, expiration dates, and lot numbers, to help businesses keep a complete inventory audit trail. This helps to prevent errors, reduce theft, and ensure accurate reporting for compliance purposes.

Effective Inventory Control Best Practices Help Streamline Workflow Processes

An inventory control system streamlines workflow processes by providing automated alerts for low stock levels, generating automated purchase orders, and helping to optimize order fulfillment. It can also help to reduce labor costs by automating manual processes, reducing the need for manual data entry, and enabling more efficient inventory management. This ultimately helps businesses to save time and money, while ensuring accurate inventory tracking and improved customer satisfaction.

Cloud-Based Storage Means You Can Manage Inventory Anytime, Anywhere

An inventory control system is accessible anytime, anywhere due to cloud-based storage. This allows businesses to access all aspects of inventory records and data from any device with an internet connection, enabling real-time visibility of stock levels and inventory movements. Additionally, cloud-based storage ensures data is secure and backed up, allowing businesses to easily access their inventory information whenever and wherever they need it.

Real-time Information Access Informs Inventory Decision-Making

An inventory control system provides effective decision-making via real-time information access. By providing up-to-date data on inventory items and movements, businesses can make informed decisions about when to order more stock, when to restock shelves, and how to optimize their supply chain. This allows them to maximize their profits and ensure that customers always have access to the products they need.

Provide Better Customer Service Through Accurate Order Fulfillment

An inventory control system improves customer service through accurate order fulfillment. By providing real-time visibility into stock levels and inventory movements, businesses can ensure that orders are fulfilled quickly and accurately. This helps to reduce wait times and improve customer satisfaction, resulting in increased sales and customer loyalty.

Improved Team Collaboration Helps Everyone in Your Company

A system for controlling a business's inventory improves team collaboration by automating tasks and providing shared access to inventory data. This allows teams to work together more efficiently, by sharing data and insights in real time. Additionally, automated tasks help to streamline processes, ensuring that inventory management tasks are completed quickly and accurately.

Automated Stock-Level Alerts Ensure Enhanced Security

A physical inventory control system enhances security by providing automated stock-level alerts. By keeping track of stock levels in real-time, businesses can be alerted when stock levels are running low, protecting against theft and loss. This helps to ensure that stock levels are always accurate and up-to-date, resulting in improved efficiency and more secure operations.

Never Wonder About Your Inventory Again with SkuNexus

For eCommerce brands of any size, an array of challenges exist at the intersection of inventory, order management, and warehouse fulfillment, and even the slightest disorganization has the potential to devolve into chaos. To counter this, the establishment and maintenance of an inventory control system is mission-critical.

Sk u N ex us offers a suite of powerful tools that can help e Commerce companies identify any in effic iencies in their processes and maintain tight inventory control . Our integrations with major eCommerce platforms automatically synchronize product data and inventory levels across channels, so companies can ensure accurate and up-to-date information is available at all times. With these tools , merchants can also gain insight into their product performance and make informed decisions about their inventory .

At SkuNexus, control is at the center of the management software solutions we design. Helping eCommerce businesses take, and keep, control over all their backend operations is a core element of what we do. If you would like to learn more about how we can help your business optimize its inventory control and reap a host of other benefits, please contact our team to schedule a thorough product demo .

SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

- Marketplace

- Privacy Policy

Get our newsletter

- ERP Services

Next Chapter:

Inventory Control and Planning: Definition, Importance, and Challenges