Implementation of Total Quality Management (TQM): Toyota Case Study

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

Introduction

Implementation of tqm in toyota, tqm practices in toyota, benefits of tqm in toyota, examples of tqm in toyota, toyota quality management, toyota tqm implementation challenges.

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business.

It requires that quality management standards be applied in all branches and at all levels of the organization. The characteristic of Toyota Corporation going through the total quality process is unambiguous and clear.

Toyota has limited interdepartmental barriers, excellent customer and supplier relations, spares time to be spent on training, and the recognition that quality is realized through offering excellent products as well as the quality of the entire firm, including personnel, finance, sales, and other functions.

The top management at Toyota Corporation has the responsibility for quality rather than the employees, and it is their role to provide commitment, support, and leadership to the human and technical processes (Kanji & Asher, 1996).

Whereas the TQM initiative is to succeed, the management has to foster the participation of Toyota Corporation workers in quality improvement and create a quality culture by altering attitudes and perceptions towards quality.

This research report assesses the implementation of TQM and how Toyota manages quality in all organization management systems while focusing on manufacturing quality. The report evaluates the organization management elements required when implementing TQM, identifies, and investigates the challenges facing Quality Managers or Executives in implementing Quality Management Systems.

In order to implement TQM, Toyota corporations focused on the following phases:

- The company extended the management responsibility past the instantaneous services and products

- Toyota examined how consumers applied the products generated, and this enabled the company to develop and improve its commodities

- Toyota focused on the insubstantial impacts on the procedures as well as how such effects could be minimized through optimization

- Toyota focused on the kaizen (incessant process development) in order to ensure that all procedures are measurable, repeatable, and visible.

The commitment from business executives is one of the key TQM implementation principles that make an organization successful. In fact, the organizational commitment present in the senior organizational staff ranges from top to lower administration. These occur through self-driven motives, motivation, and employee empowerment. Total Quality Management becomes achievable at Toyota by setting up the mission and vision statements, objectives, and organizational goals.

In addition, the TQM is achievable via the course of active participation in organizational follow-up actions. These actions denote the entire activities needed and involved during the implementation of the set-out ideologies of the organization. From Toyota Corporation’s report, TQM has been successful through the commitment of executive management and the organizational workforce (Toyota Motor Corporation, 2012).

Through inventory and half the bottlenecks at half cost and time, the adopters of TMS (Toyota Management System) are authorized to manufacture twice above the normal production. To manage the quality in all organizational management systems, the Toyota Production System incorporates different modernisms like strategy or Hoshin Kanri use, overall value supervision, and just-in-time assembly.

The amalgamation of these innovations enables Toyota to have a strong competitive advantage despite the fact that Toyota never originated from all of them. The 1914 Henry Ford invention relied on the just-in-time production model. The Ford system of production, from a grand perspective, warrants massive production, thus quality (Toyota Motor Corporation, 2012).

Kanji and Asher (1996) claim that to manage the minute set of production necessitated by the splintered and small post-war marketplaces, the JIT system focuses on the motion and elimination of waste materials. This reduces crave for work-in-process inventory by wrapping up the long production lines. Toyota Corp wraps the production lines into slashed change-over times, a multi-trained workforce that runs manifold machines, and new-fangled cells into a U shape.

When supplementing the just-in-cells, the system of kanban is employed by the Toyota Corporation to connect the cells that are unable to integrate physically. Equally, the system helps Toyota integrate with other external companies, consumers, and suppliers.

The TQM and the creativity of Toyota proprietors both support the quality at the source. The rectification and discovery of the production problems require the executives to be committed. At the forefront of Toyota operations, the managers integrate a number of forms of operational quality checks to ensure quality management at all levels.

The uninterrupted tests help the Toyota workforce engaging in the assembly course to scrutinize the value of apparatus, implements, and resources utilized in fabrication. The checks help in the scrutiny of the previously performed tasks by other workers. However, the corporation’s own test enables the workers to revise their personal advances in the assembly course.

The Toyota process owners set up the mistake-proofing (Poka-yoke) procedures and devices to capture the awareness of management and involuntarily correct and surface the augmenting problems. This is essential for the critical production circumstances and steps that prove impractical and tricky for Toyota employees to inspect.

Nevertheless, the policy deployment system decentralizes the process of decision-making at Toyota. This context of implementing Total Quality Management originates from Hoshin Kanri’s management by objective (MBO).

This aspect becomes more advantageous to Toyota when dealing with quality management. The system initially puts into practice the coordinated approach and provides a clear structure for the suppliers, producers, and consumers through inter-organizational cost administration. Moreover, Toyota executives can solve the concurrent delivery, cost, and quality bottlenecks, thus replacing and increasing the relatively slow accounting management mechanisms.

Customer focus that leads to the desired customer satisfaction at Toyota Company is one of the major success factors in TQM implementation. For every business to grow, it should have understanding, reliable, and trustworthy customers. The principle of customer satisfaction and focus has been the most presently well-thought-out aspect of Toyota’s manufacturing quality.

The TQM may characteristically involve total business focus towards meeting and exceeding customers’ expectations and requirements by considering their personal interests. The mission of improving and achieving customer satisfaction ought to stream from customer focus.

Thus, when focusing on manufacturing quality, this aspect enhances TQM implementation. The first priorities at Toyota are community satisfaction, employees, owners, consumers, and mission. The diverse consumer-related features from liberty. The concern to care is eminent in Toyota Corporation during manufacturing.

Toyota has three basic perspectives of TQM that are customer-oriented. These are based on its manufacturing process traced back to the 1950s. The strategies towards achieving quality manufacturing, planning, and having a culture towards quality accomplishment are paramount for TQM implementation to remain successful. To enhance and maintain quality through strategic planning schemes, all managers and employers must remain effectively driven.

This involves training workers on principles concerning quality culture and achievement. Scheduling and planning are analytical applications at Toyota Company that purposes in assessing customer demand, material availability, and plant capacity during manufacturing.

The Toyota Corporation has considerable approaches that rank it among the successful and renowned implementers of TQM. From the inherent and designed structure of Toyota, it becomes feasible to comprehend why quality manufacturing is gradually becoming effective. The inspection department is responsible for taking corrective measures, salvaging, and sorting the desired manufactured product or service quality.

The Toyota Corporation also has a quality control system that is involved in determining quality policies, reviewing statistics, and establishing quality manuals or presentation data. Furthermore, quality assurance is one of the integral principles in quality implementation that is practically present at Toyota. The quality assurance and quality inspectors throughout the Toyota Company structure also manage research and development concerning the quality of manufactured products and services.

The Toyota production and operations management system is similarly dubbed as the managerial system. In fact, in this corporation, operational management is also referred to as the production process, production management, or operations (Chary, 2009). These simply incorporate the actual production and delivery of products.

The managerial system involves product design and the associated product process, planning and implementing production, as well as acquiring and organizing resources. With this broad scope, the production and operation managers have a fundamental role to play in the company’s ability to reach the TQM implementation goals and objectives.

The Toyota Corporation operations managers are required to be conversant and familiar with the TQM implementation concepts and issues that surround this functional area. Toyota’s operation management system is focused on fulfilling the requirements of the customers.

The corporation realizes this by offering loyal and express commodities at logical fees and assisting dealers in progressing commodities proffered. As Slack et al. (2009) observed, the basic performance objectives, which pertain to all the Toyota’s operations, include quality, speed, flexibility, dependability, and cost. Toyota Company has been successful in meeting these objectives through its production and operation functions.

Over several decades, Toyota’s operational processes and management systems were streamlined, resulting in the popularly known Toyota Production System. Although the system had been extensively researched, many companies, such as Nissan, experienced difficulties in replicating TPS.

The TPS was conceived when the company realized that producing massive quantities from limited product lines and ensuring large components to achieve maximum economies of scale led to flaws. Its major objectives were to reduce cost, eliminate waste, and respond to the changing needs of the customers. The initial feature of this system was set-up time reduction, and this forms the basis of TQM implementation.

At Toyota Corporation, quality is considered as acting responsibly through the provision of blunder-gratis products that please the target clientele. Toyota vehicles are among the leading brands in customer satisfaction. Due to good quality, its success has kept growing, and in 2012, the company was the best worldwide. Moreover, Toyota has been keen on producing quality vehicles via the utilization of various technologies that improve the performance of the vehicles.

While implementing TQM, Toyota perceives speed as a key element. In this case, speed objective means doing things fast in order to reduce the time spent between ordering and availing the product to the customer.

The TPS method during processing concentrates on reducing intricacy via the use of minute and uncomplicated machinery that is elastic and full-bodied. The company’s human resources and managers are fond of reorganizing streams and designs to promote minimalism. This enhances the speed of production.

Another objective during TQM implementation is dependability. This means timely working to ensure that customers get their products within the promised time. Toyota has included a just-in-time production system comprised of multi-skilled employees who work in teams. The kanban control allows the workers to deliver goods and services as promised. Advancing value and effectiveness appears to be the distress for administrators, mechanical specialists, and other Toyota human resources.

During TQM implementation, Toyota responds to the demands by changing its products and the way of doing business. Chary (2009) argues that while implementing TQM, organizations must learn to like change and develop responsive and flexible organizations to deal with the changing business environment.

Within Toyota plants, this incorporates the ability to adopt the manufacturing resources to develop new models. The company is able to attain an elevated degree of suppleness, manufacturing fairly tiny bunches of products devoid of losses in excellence or output.

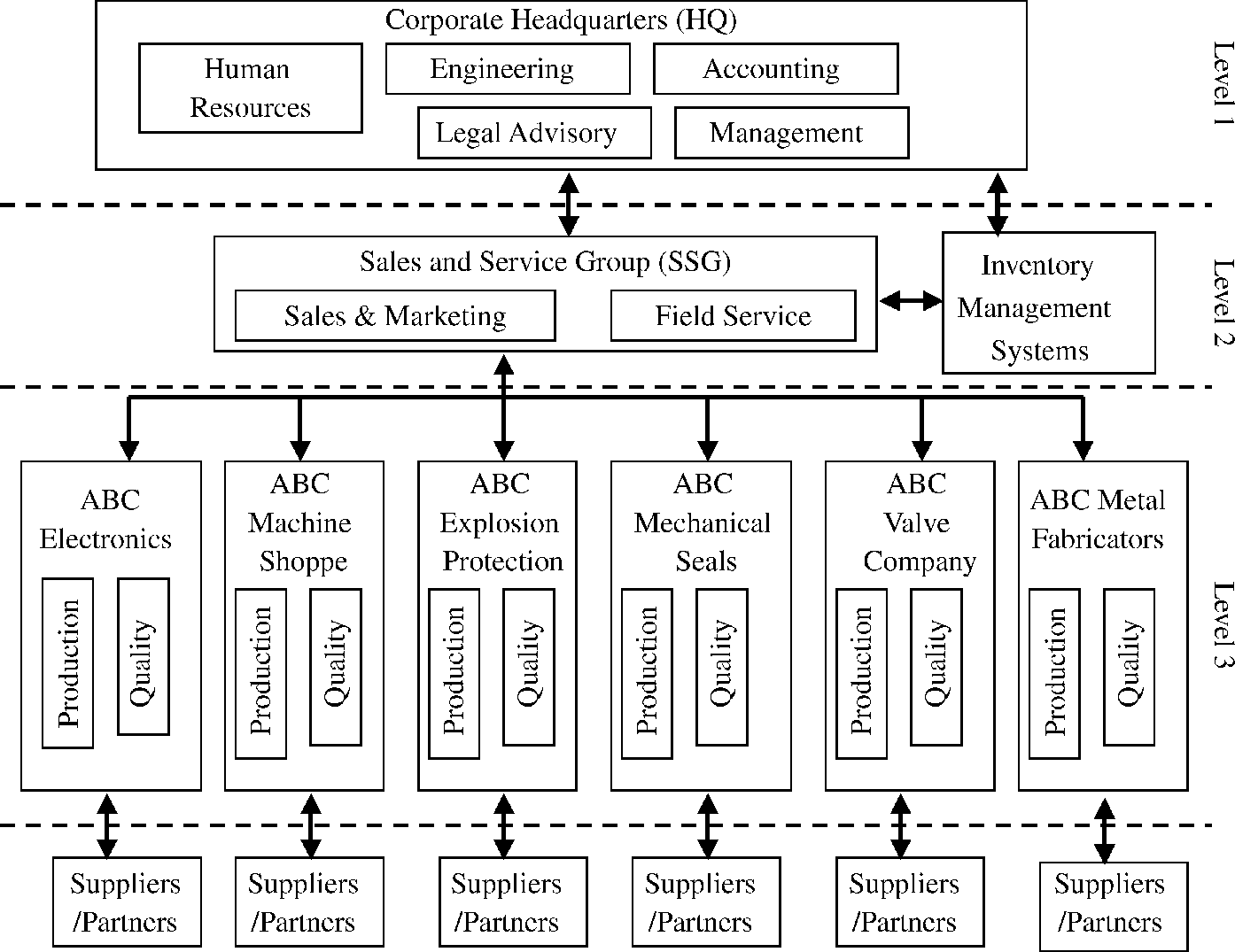

The organizational hierarchy and job descriptions also determine the successful implementation of the TQM. Toyota is amongst the few companies whose organizational structure and task allocation have proved viable in TQM implementation. The company has three levels of management. See the diagram below.

Management hierarchy

Despite the hierarchy and task specification, employees are able to make independent decisions and take corrective measures when necessary to ensure quality during production. Team working is highly encouraged at Toyota Corporation, and this plays a significant role during TQM implementation. All stakeholders are incorporated in quality control initiatives to ensure client demands are satisfied.

However, all employees are required to carry out their assigned tasks, and the management closely supervises the ways of interactions between workers. The management ensures that the manufacturing lines are well-built and all employees are motivated to learn how to improve the production processes.

Toyota is among the few manufacturers in the complete automobile industry that consistently profited during the oil crisis in 1974. The discovery was the unique team working of the Japanese that utilized scientific management rules (Huczynski & Buchanan, 2007).

The joint effort in Japan, usually dubbed Toyotaism, is a kind of job association emphasizing ‘lean-assembly.’ The technique merges just-in-time production, dilemma-answering groups, job equivalence, authoritative foremost-streak administration, and continued procedure perfection.

Just-in-time (JIT) assembly scheme attempts to accomplish all clients’ needs instantly, devoid of misuse but with ideal excellence. JIT appears to be dissimilar from the conventional functional performances in that it emphasizes speedy production and ravage purging that adds to stumpy supply.

Control and planning of many JIT approaches are concerned directly with pull scheduling, leveled scheduling, kanban control, synchronization of flow, and mixed-model scheduling (Slack et al., 2009).

Toyota appears to be amongst the principal participants in changing Japan to a kingpin in car production. Companies, which have adopted the company’s production system, have increased efficiency and productivity. The 2009 industrial survey of manufacturers indicates that many world-class firms have adopted continuous-flow or just-in-time production and many techniques Toyota has been developing many years ago.

In addition, the manufacturing examination of top plant victors illustrates that the mainstream them utilize lean production techniques widely. Thus, team-working TPS assists Toyota Corporation in the implementation of TQM.

Executives and Quality Managers face some challenges while implementing Quality Management Systems in organizations. In fact, with a lack of the implementation resources such as monetary and human resources in any organization, the implementation of TQM cannot be successful. Towards the implementation of programs and projects in organizations, financial and human resources have become the pillar stones.

The approach of TQM impels marketplace competence from all kinds of organizational proceeds to ensure profitability and productivity. To meet the desired results in TQM implementation, an organization ought to consider the availability of human and financial resources that are very important for the provision of an appropriate milieu for accomplishing organizational objectives.

In the case of Toyota, which originated and perfected the philosophy of TQM, the Executives, and Quality Managers met some intertwined problems during TQM implementation. The flaw in the new product development is increasingly becoming complicated for the managers to break and accelerate, thus creating reliability problems. Besides, secretive culture and dysfunctional organizational structure cause barriers in communication between the top management, thus, in turn, augmenting public outrage.

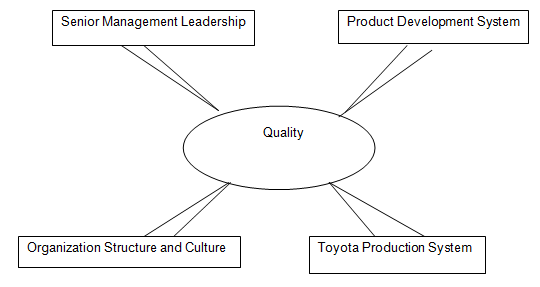

The top executives may fail to provide and scale up adequate training to the suppliers and new workforces. As a result, cracks are created in the rigorous TPS system. In addition, a lack of leadership at the top management might cause challenges in the implementation of TQM. Therefore, in designing the organizational structures and systems that impact quality, the senior executives and managers must be responsible, as elaborated in Figure 2 below.

Total Quality Management is a concept applied in the automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Being part of Toyota, the concept defines the way in which the organization can create value for its customers and other stakeholders. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies.

These efficiencies have particularly been achieved by continuous correction of deficiencies identified in the process. A particular interest is the central role that information flow and management have played in enabling TQM initiatives to be implemented, especially through continuous learning and team working culture.

The Toyota way (kaizen), which aims at integrating the workforce suggestions while eliminating overproduction and manufacturing wastes, helps the company to respect all the stakeholders and give clients first priority. The objectives are realized through TPS.

Chary, D. 2009, Production and operations management , Tata McGraw-Hill Education Press, Mumbai.

Huczynski, A. & Buchanan, D. 2007, Organizational behavior; an introductory text, Prentice Hall, New York, NY.

Kanji, G. K. & Asher, M. 1996, 100 methods for total quality management , SAGE Thousands Oak, CA.

Slack, N. et al. 2009, Operations and process management: principles and practice for strategic management, Prentice Hall, New York, NY.

Toyota Motor Corporation 2012, Annual report 2012. Web.

- First World Hotel: Just-in-Time Manufacturing Model

- Motorola Company's Just-in-Time Implementation

- Lean Manufacturing: Processes

- Barriers and Facilitators of Workplace Learning

- The Science of Behavior in Business

- Standards, models, and quality: Management

- Managerial and Professional Development: Crowe Horwath CPA limited

- Managerial and Professional Development: Deloitte & Touché Company

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2019, June 12). Implementation of Total Quality Management (TQM): Toyota Case Study. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/

"Implementation of Total Quality Management (TQM): Toyota Case Study." IvyPanda , 12 June 2019, ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

IvyPanda . (2019) 'Implementation of Total Quality Management (TQM): Toyota Case Study'. 12 June.

IvyPanda . 2019. "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

1. IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

Bibliography

IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

- Toyota's Approach to Quality Management: Tools and Techniques

In the world of automotive manufacturing, the name 'Toyota' is synonymous with quality, reliability, and innovation. From its humble beginnings in Japan to its position as a global automotive leader, Toyota's unwavering commitment to quality management has been instrumental in its success. In this article, we'll delve deep into Toyota's approach to quality management, exploring the tools and techniques that have been pivotal in establishing its reputation.

1. The Toyota Production System (TPS)

At the heart of Toyota's approach to quality management lies the Toyota Production System (TPS), a set of principles and practices designed to reduce waste and improve efficiency. TPS focuses on two main principles:

- Jidoka (Automation with a Human Touch) : It involves integrating automation with human intervention. If a problem arises during the production process, the machine stops automatically, preventing defective products from being produced.

- Just-in-Time (JIT) : This principle is about producing only what is needed when it is needed, and in the amount needed. It reduces inventory costs and improves cash flow.

2. Kaizen: Continuous Improvement

Toyota's culture is deeply rooted in the philosophy of Kaizen, which translates to "continuous improvement". Employees at every level are encouraged to suggest improvements, no matter how minor. This grassroots approach ensures that improvements are holistic and come from those directly involved in the process.

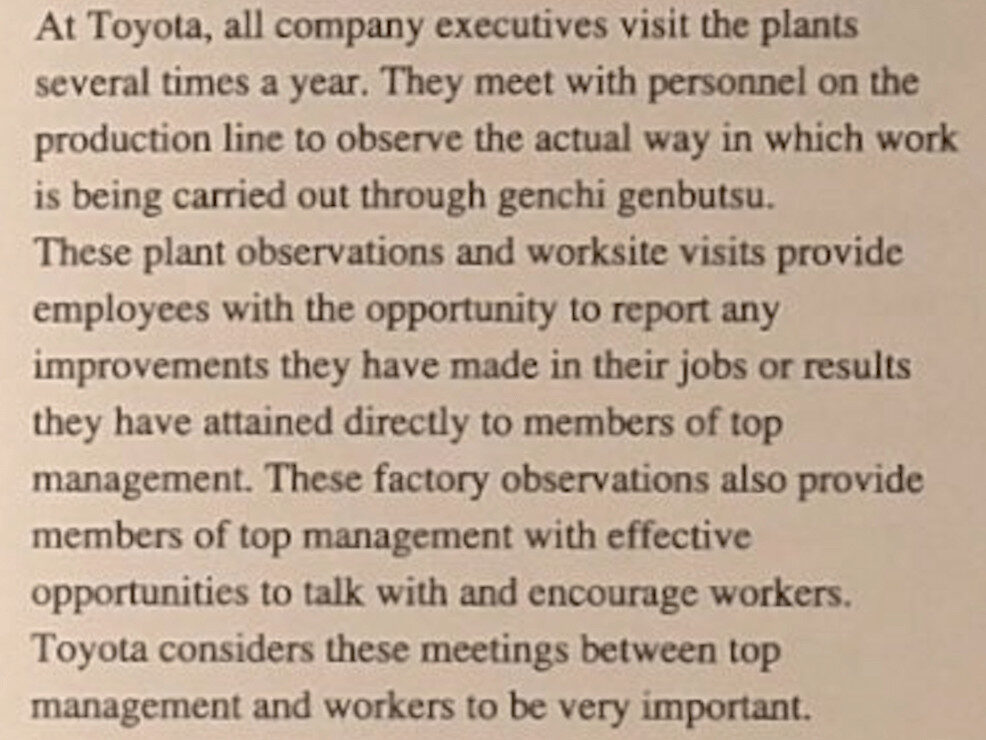

3. Genchi Genbutsu: Go and See

Literally translating to "go and see for yourself", this principle emphasizes the importance of understanding a situation firsthand, rather than relying on secondhand reports. It promotes hands-on problem solving, ensuring decisions are based on a deep understanding of the situation.

4. Kanban System

Toyota introduced the Kanban system to control the logistical chain from a production standpoint. It uses a card (or 'Kanban') to signal when more goods are needed in the production process, ensuring a consistent supply without overstocking.

5. Root Cause Analysis

When a problem arises, Toyota doesn't just focus on fixing the immediate issue. Using techniques like the "5 Whys", they delve into the root cause of the problem, ensuring it doesn't recur in the future.

6. Standardized Work

For Toyota, standardization isn't about making processes rigid. It's about establishing the best current method and ensuring everyone follows it. This creates a consistent baseline, making improvements easier to identify and implement.

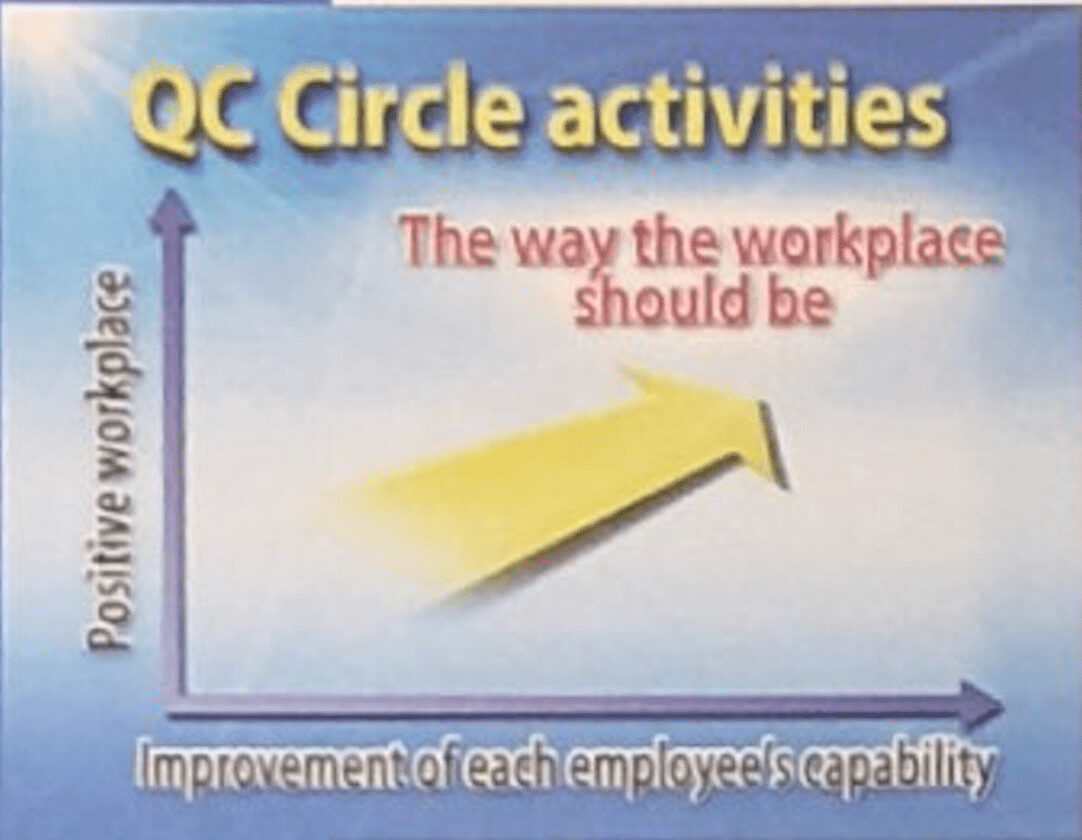

7. Quality Circles

Quality circles are small groups of workers who come together to discuss and solve problems related to work. This collaborative approach ensures diverse perspectives and innovative solutions.

8. Poka-Yoke: Mistake-Proofing

Originating from TPS, Poka-Yoke is a technique to prevent mistakes by designing the process in such a way that errors are impossible or immediately noticeable.

9. Supplier Involvement

Toyota doesn't just focus on its own quality management. They work closely with suppliers, ensuring that parts meet their stringent quality standards. This partnership approach ensures consistency throughout the production chain.

10. Visual Control

Clear visuals help workers quickly identify abnormalities. From colored tags to marked floors, Toyota uses visual cues to maintain standards and quickly spot deviations.

Benefits of Toyota's Quality Management Approach

Toyota's commitment to quality has yielded several benefits:

- Customer Loyalty : Toyota vehicles are known for their reliability, leading to high levels of customer satisfaction and loyalty.

- Operational Efficiency : Their focus on waste reduction and efficiency has led to cost savings and increased profitability.

- Innovative Culture : By valuing employee feedback and fostering a culture of continuous improvement, Toyota remains at the forefront of automotive innovation.

Toyota's quality management isn't just about tools and techniques—it's a culture. Their holistic approach, which values employees' insights, customer satisfaction, and long-term thinking, has set them apart in the automotive industry. For businesses looking to elevate their quality standards, Toyota offers a masterclass in how it's done.

With these insights into Toyota's approach to quality management, it becomes evident that their success isn't accidental. It's a result of decades of dedication, innovation, and a relentless pursuit of excellence.

Related Posts

- The Toyota Way Is More than Tools and Techniques - So you set up your kanban system. (Kanban is the Japanese word for “card,” “ticket,” or “sign” and is a tool for managing the flow and production of materials in...

- The Essence of Toyota Management System - Table of Contents The History and Evolution of TMS The Core Principles of TMS Practices & Techniques Modern Adaptations of TMS The Future of TMS In the world of management,...

- The Role of Leadership in Toyota's Management Culture - Toyota, as a global juggernaut, is more than just its cars; it’s a representation of a deeply embedded culture of excellence. At the heart of this culture is the pivotal...

- The Origins of the Toyota Management System - The Toyota Management System (TMS), often interchangeably referred to as the Toyota Production System (TPS), is an iconic example of innovation and operational efficiency. Its impact resonates beyond the automobile...

- Now Toyota’s Tools Make More Sense - Toyota’s tools and techniques become more understandable, and effective, when we view them in the context of striving to achieve a target condition by working step by step through obstacles....

- Understanding Toyota's 5 Whys Approach to Problem Solving - Toyota, a global powerhouse in the automotive industry, is not just renowned for its cars, but also for its unique management principles. Among these principles, the "5 Whys" approach stands...

- Incorporating Lean Principles: Lessons from Toyota - Toyota, an automotive giant, has long been lauded not only for its impeccable quality and innovative designs but also for its operational excellence. The Toyota Production System (TPS), the company's...

- Six Sigma, Lean Tools, and Lean Sigma: Just a Bunch of Tools? - There are many “tools” approaches to organization improvement. One very popular program, which General Electric adopted with great success, is Six Sigma, an extension of Total Quality Management (TQM). Six...

- The Principle: Standardization Is the Basis for Continuous Improvement and Quality - Toyota’s standards have a much broader role than making shop floor workers’ tasks repeatable and efficient. The Toyota Way results in standardized tasks throughout the company’s white-collar work processes, such...

- The 14 Principles of the Toyota Way - The Toyota Way, a management philosophy that has propelled Toyota to its current position as a global leader in efficiency and quality, is underpinned by 14 key principles. These principles...

- Toyota's Global Expansion: Strategies and Challenges

- Toyota's Cross-cultural Communication Strategies in Global Operations

- Toyota's Supplier Relationship Management: Building Long-Term Partnerships

- Toyota Logistics Operation

- Toyota's Joint Ventures and Strategic Alliances

- Toyota's Six Sigma Approach and Its Implementation

- Toyota's Digital Transformation in Manufacturing

- How Toyota's Just-In-Time (JIT) System Revolutionized Manufacturing

- Training and Development: Toyota's Investment in its Employees

- Get Posts Sent via Email

- Contributors

- Most Popular

- Most Commented

- Lean Comedy

- Podcast Home

- Browse Episodes

- Episode Collections

- Podcast Home & Subscribe

- Lean Whiskey

- My Favorite Mistake

- Practicing Lean

- Toyota Kata Podcast

- Featured Videos

- YouTube Channel

- Via MarkGraban.com

- About Mark Graban

- About the Blog

- What is “Lean”?

- Standardized Work

- Privacy Tools

- Healthcare Improvement

- Lean-Focused Blogs

- Lean Healthcare Blogs

- Other Blogs

- Lean Resources

- Contact Form

- Get Posts via Email

- Mark’s Newsletter

TQM at Toyota and the Influence on Lean – Past and Present, Japan and U.S.

I'm very excited to be leaving for Japan for another study trip in a month. This will be my second trip this year, this time with Honsha , after previous (and hopefully future) trips organized by Kaizen Institute.

I learn something each time and I've started reflecting a bit on the previous trips. There's still a lot that I haven't blogged about from the last trip.

Even though the previous tours have been focused on Toyota, as well as Lean and Kaizen in various organizations, one common thread is Total Quality Management, or TQM. In many Japanese organizations, TQM has been a solid foundation of practice for two or three decades, where it tended to be a fad here in the U.S., as I've blogged about :

From 1994, But Relevant Today: “Why TQM Fails” & Parallels to Lean

Methods like TQM, Kaizen, or Lean tend to “fail” when an organization gives up on them.

As I mentioned in this webinar recently, when I first visited the Toyota plant in San Antonio a few years ago, one of the people in the tour group was a Six Sigma (or Lean Sigma?) Master Black Belt. He asked the Toyota team member if they use Six Sigma and they said:

“No, but we teach everybody the seven basic Q.I. tools .”

They were, of course, referring to TQM.

When I've visited Japan, TQM has come up as a topic, as I blogged about here :

“Quality Circles” Are Alive & Well in Japanese Organizations; We Might Call it A3 Problem Solving

TQM at Toyota in the U.S.

And, more recently, Tracey Richardson (formerly of Toyota in Kentucky) was sharing some old Toyota materials that directly reference TQM. I've embedded these below for my own future reference (and yours):

Her Day 9 post references control charts (which I write about in my book Measures of Success ) .

Again, Toyota doesn't use formal Six Sigma (with “belts” and all) in the factories, but they do, again, teach everybody the “ seven basic Q.I. tools ” of TQM, which includes control charts (a.k.a. SPC or Statistical Process Control).

Here's the rest of the TQM material from Tracey…

As I've heard them say in Japan, we “spin the PDCA cycle” as we improve in experimental and incremental ways. I wrote about PDCA/PDSA last week .

More about Lean / TPS and quality:

What Toyota Shared in Japan

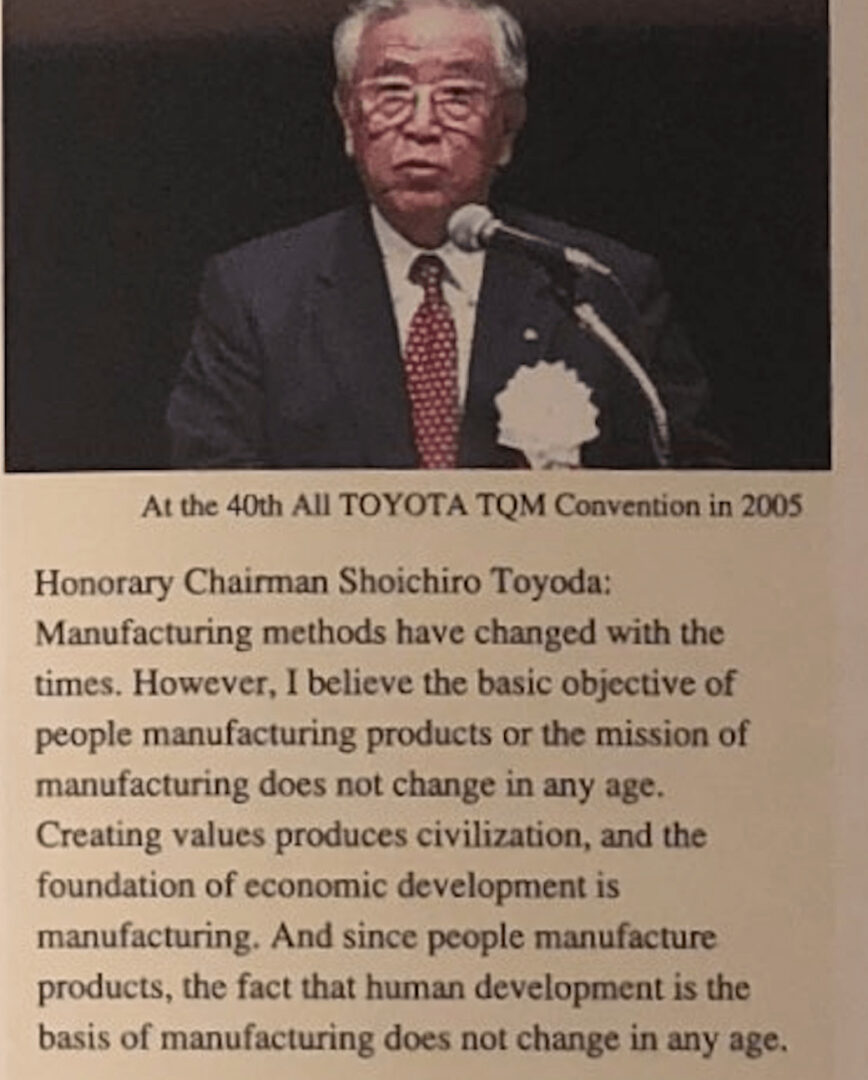

During my last trip, we visited a hospital that had some Toyota people coaching and mentoring physicians on quality improvement. They shared a TQM guidebook that wasn't shared in the Toyota plant tour. The cover is pictured here:

The first page of the book lists some “Guiding Principles” that include “[fostering] a corporate culture that enhances individual creativity and teamwork value, while honoring mutual trust between labor and management” and “[pursuing] growth in harmony with the global community through innovative management.”

The booklet also says “all personnel” need to “fully demonstrate the best of their unique abilities” in order for the company to be successful.

“TQM activities serve as the foundation for achieving that goal [of ‘creating better cars'] and the entire Toyota family is engaged in TQM activities.”

Toyota adopted “QC training” as a method in 1951 and “started to popularize the quality control concept along with the acquisition of statistical tools.”

Who is to say that Six Sigma has a monopoly on the use of statistical tools?

Toyota then adopted “TQC” (Total Quality Control) in 1961 as a further evolution of quality methods. Toyota was awarded the Deming Prize in 1965. They switched from the TQC term to TQM in 1995.

I love Toyota's description of “genchi genbutsu” (referenced in Tracey's one post) or the practice of “going to see” at the “gemba” (the workplace).

I'm often part of efforts to show hospital executives to follow this same practice to the benefit of their organizations. It's always eye-opening for the executives. What have you seen with executives learning to “go and see?”

The booklet also talks again about the importance of people development and how “timeless” that notion is.

Different Modes of Improvement

I blogged about “quality circles” in the post I mentioned earlier and Toyota says they use quality circles to improve quality, cost, and safety.

“There are currently 4,500 circles…”

Toyota also mentions their “Creative Suggestion System,” where “more than 550,000 suggestions are submitted annually.” They add:

“The fact that nearly all of these suggestions are adopted indicates the high quality of their contents.”

We can call that a “ Kaizen ” methodology. Either way, compare that implementation rate to the classic American “suggestion box” system that has historically seen just a 2% acceptance rate or so.

We see similarly high adoption rates (80% or more) in American hospitals that practice the Toyota style of Kaizen .

More about suggestions, engagement, pride, and quality:

As an aside, I posted another complaint on LinkedIn the other day about the common problem of “Lean Sigma” saying things like “Lean is about speed” (or cost or efficiency) and implying that only Six Sigma can improve quality.

See more about Toyota, TQM, and Lean in the next post in this series:

How Toyota Teaches a Japanese Hospital's Doctors About TQM

What do you think? Please scroll down ( or click ) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation :

Get New Posts Sent To You

Check your inbox or spam folder to confirm your subscription.

RELATED ARTICLES MORE FROM AUTHOR

Throwback Thursday: The Suggestion Box is Dead, with a New Obituary

Don’t Digitize the Suggestion Box — Improve a Better Way with Kaizen and KaiNexus

I’ll Be Speaking, Learning, and Facilitating at the Global Lean Summit

Hi Mark – Your post, and Tracey’s LinkedIn images, wonderfully demonstrate how Toyota is a rare example of a large company whose senor management has long been committed to running the business according to the facts (de facto), which is in contrast to companies whose senior management is committed to running the business according to “rightful entitlement” (de jure). It is heartening to see organizations in which senior managers have been able to accept de facto thinking and routines to guide management decision-making. We all wish there were a lot more of them.

A follow-up comment: de facto is really the essence of TPS and The Toyota Way. They developed various methods and tools over the years that make people face reality so that the facts cannot be avoided, and so that action is taken based on the facts — in all levels of the hierarchy, from worker to president. This also shows a level of caring for the business and its stakeholders that is hard to find in other big companies, not to mention innovation in management practice and leadership. It is remarkable Toyota management has been able to prevent a complete takeover by de jure (which almost happened under former president Hiroshi Okuda).

The inability of large American companies to have any constancy of purpose is really astonishing. Its like they suffer from sort of chronic Attention Deficit.

Many thanks Mark for sharing this valuable & insightful post. For long time I haven’t heard about TQM except in training or Educational programs. I highly believe in TQM and that it’s the big umbrella that all attractive names like 6 sigma, Lean, Kaizen, etc. can fall under it.

Also thanks for consolidating the valuable & comprehensive posts from Tracey Richardson about Quality Circles & Problem Solving here as well.

Wishing you good luck in your trip.

Here is what Tracey shared about Toyota’s articulation of the 7 QC tools on Linkedin .

LEAVE A REPLY Cancel reply

Yes, email me about new posts, daily!

This site uses Akismet to reduce spam. Learn how your comment data is processed .

EVEN MORE NEWS

Ryan McCormack’s Operational Excellence Mixtape: June 28, 2024

Recording: The Mistakes That Make Us: A Book Birthday Event

POPULAR CATEGORY

- Interviews 498

- Mixtape 142

- Lean Whiskey 46

- Lean Blog Interviews

- Lean Blog Audio

- Privacy Policy

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

The Contradictions That Drive Toyota’s Success

- Hirotaka Takeuchi,

- Norihiko Shimizu

Stable and paranoid, systematic and experimental, formal and frank: The success of Toyota, a pathbreaking six-year study reveals, is due as much to its ability to embrace contradictions like these as to its manufacturing prowess.

Reprint: R0806F

Toyota has become one of the world’s greatest companies only because it developed the Toyota Production System, right? Wrong, say Takeuchi, Osono, and Shimizu of Hitotsubashi University in Tokyo. Another factor, overlooked until now, is just as important to the company’s success: Toyota’s culture of contradictions.

TPS is a “hard” innovation that allows the company to continuously improve the way it manufactures vehicles. Toyota has also mastered a “soft” innovation that relates to human resource practices and corporate culture. The company succeeds, say the authors, because it deliberately fosters contradictory viewpoints within the organization and challenges employees to find solutions by transcending differences rather than resorting to compromises. This culture generates innovative ideas that Toyota implements to pull ahead of competitors, both incrementally and radically.

The authors’ research reveals six forces that cause contradictions inside Toyota. Three forces of expansion lead the company to change and improve: impossible goals, local customization, and experimentation. Not surprisingly, these forces make the organization more diverse, complicate decision making, and threaten Toyota’s control systems. To prevent the winds of change from blowing down the organization, the company also harnesses three forces of integration: the founders’ values, “up-and-in” people management, and open communication. These forces stabilize the company, help employees make sense of the environment in which they operate, and perpetuate Toyota’s values and culture.

Emulating Toyota isn’t about copying any one practice; it’s about creating a culture. And because the company’s culture of contradictions is centered on humans, who are imperfect, there will always be room for improvement.

No executive needs convincing that Toyota Motor Corporation has become one of the world’s greatest companies because of the Toyota Production System (TPS). The unorthodox manufacturing system enables the Japanese giant to make the planet’s best automobiles at the lowest cost and to develop new products quickly. Not only have Toyota’s rivals such as Chrysler, Daimler, Ford, Honda, and General Motors developed TPS-like systems, organizations such as hospitals and postal services also have adopted its underlying rules, tools, and conventions to become more efficient. An industry of lean-manufacturing experts have extolled the virtues of TPS so often and with so much conviction that managers believe its role in Toyota’s success to be one of the few enduring truths in an otherwise murky world.

- Hirotaka Takeuchi is a professor in the strategy unit of Harvard Business School.

- EO Emi Osono ( [email protected] ) is an associate professor;

- NS and Norihiko Shimizu ( [email protected] ) is a visiting professor at Hitotsubashi University’s Graduate School of International Corporate Strategy in Tokyo. This article is adapted from their book Extreme Toyota: Radical Contradictions That Drive Success at the World’s Best Manufacturer , forthcoming from John Wiley & Sons.

Partner Center

We use cookies to enhance our website for you. Proceed if you agree to this policy or learn more about it.

- Essay Database >

- Essay Examples >

- Essays Topics >

- Essay on Employee

Total Quality Management In Toyota Case Study Examples

Type of paper: Case Study

Topic: Employee , Training , Teamwork , Development , Toyota , Workplace , Management , Education

Words: 1100

Published: 01/05/2020

ORDER PAPER LIKE THIS

1) List the principles of TQM in Toyota and discuss how Toyota implements the principles. Provide examples in every point.

Total Quality Management is a combined effort of management philosophy with a set of practices that lays emphasis on continuous improvement, meet the requirements of the customer, reduce rework, think on a longer range, involve employees at all stages and teamwork, process redesign, solve the issues with the help of team members, measure the results constantly and always have good relationships with suppliers. Total Quality Management in Toyota is entirely based on “Customer First” criterion with an equal importance to “Continuous Kaizen” and “Total Participation”. To achieve these, the automobile giant has formed the following set of principles. 1. Challenge: To set a clear vision for a steady progress and meeting the requirements to upgrade to the same. Courage and creativity of every individual in the organization become the essential factors to be successful.

For example: Toyota provides its employees with human resource development and healthcare programs to bring about confidence and motivation.

2. Kaizen: To bring about continuous changes in the procedures to have perfection and overall development. For example: At Toyota, employees do not stop on achieving a set target, they are at freedom to alter practices for enhancing and speeding up the quality and production. 3. Genchi Genbustu (Vasilash, 2005): To follow the “Go and See” method of problem solving. An issue can be better resolved at the point of its cause. For example: In an event of a breakdown, the analysis is done right at the place where it occurs, and the decision is made considering the mutual consent of the employees involved and the least time to solve it. 4. Respect: To build mutual trust and responsibility for a stable employment and healthy labor-management relationship. For example: All employees are treated equally and are provided equal responsibility in decision making for the progress of the organization. 5. Teamwork: To encourage personal and professional growth by sharing the development prospects to increase individual and team performance. Toyota does not only produce cars, it produces talented people through 4P model, the Philosophy, People, Problem-Solving and Process (Liker, Meier, 2007) For example: Every individual, whether single or as a team is given an opportunity to contribute to the organizational growth with equal importance to self-development.

These combined with the “300,000 Person Communication Activities” like improving English language skills, globalization activities and forming healthy relations with overseas executive to increase workplace competence.

2) Explain what is Toyota Education System and discuss how it support the success of TQM implementation.

The Toyota Institute (TI) works toward the mission of “Human resource development that puts the Toyota Way into practice”. To attain this TI has prepared the following training programs for Toyota and its overseas affiliates. These are spread over mainly the three levels of management, the upper, the middle and the new recruits.

The following activities like the Subordinate development, Toyota Way of problem solving, Management development training, New Manager training, Training by job grade, and Expatriate training program are performed as a part of the Toyota Education System in Toyota Organization globally.

The Toyota Education system is mainly to increase the Quality of products and services at Toyota. The programs are based on “Customer first”, “Continuous Kaizen” and “Total Participation” which are the main principles of TQM. Statistical Quality Control and Quality Control, and Soikufu are also integrated in the education system to promote TQM. The R&D Learning Center Course Guide was created for all the managers to enhance the training curricula in each workplace and utilize the courses systematically, and it was made available on intranet in an attempt to spread the awareness of self-development across the organization. The employee education in Toyota is always addressed under the Genchi-genbutsu principle.

3) Discuss "Continuous Improvement" and "Respect for People" as initiatives that support the foundation of Toyota Way.

Toyota believes in Continuous Improvement and Respect for People as the fundamentals for its organizational growth. The key features that comprise Continuous improvement are Challenge, Kaizen and Genchi Genbutsu, and the key features that comprise Respect for People are the Respect and Teamwork. Toyota has a long term vision to meet the challenges with courage and creativity, by driving innovation and evolution for improving the business operations. The greatest principle of Toyota is to go and see in the shop floor to make the correct decisions during the manufacturing process, and achieve the defined goals at the best speed. Respect for people is considered the best principle as Toyota makes every effort to understand each other, build mutual trust and take responsibility. For example: An error on a shop floor may be a minor error or a major error, like assembling the correct parts in the product. Improper placements of the parts may result in delaying the assembly. So, by following the Genchi-gentubsu under Continuous Improvement principle, this error can be avoided.

4) Highlights what are quality awards being practice and implemented in Toyota.

The quality awards are achieved when every employee fulfills his or her duty at every step of the production cycle by accepting responsibilities and taking ownership so that the defects don’t occur. Quality awards are given by various foundations like the Deming Price, European Foundation of Quality Management (Anvari, Ismail, & Hojjati, 2011), Malcolm Balbridge National Quality Award (Hendricks, & Singhal 2000) and so on based on the concept for implementing the Total Quality Management. Toyota received the Japan Quality Award Quality Innovation Award from the Union of Japanese Scientists and Engineers for company-wide efforts in October 2010. This award was presented to Toyota for following the Ji Kotei-Kanketsu principle (Built-in quality with ownership).

Vasilash, Gary S., (2005, July 30). Genchi-Genbutsu and creating the Toyota 4Runner. (On Cars).: An article from: Automotive Design & Production. Retrieved from http://www.amazon.com/gp/product/B0008FK232/ref=kinw_rke_rti_1 Liker, Jeffrey., Meier, David., (2007). Toyota Talent: Developing Your People the Toyota Way. McGraw-Hill Anvari, Alireza., Ismail, Yusof., & Hossein Hojjati, Seyed Mohammad (2011). A Study on Total Quality Management and Lean Manufacturing: Through Lean Thinking Approach, IDOSI Publications. Hendricks, Kevin B., Singhal, Vinod R., (2000). The Impact of Total Quality Management (TQM) on Financial Performance: Evidence from Quality Award Winners.

Cite this page

Share with friends using:

Removal Request

Finished papers: 192

This paper is created by writer with

ID 260040626

If you want your paper to be:

Well-researched, fact-checked, and accurate

Original, fresh, based on current data

Eloquently written and immaculately formatted

275 words = 1 page double-spaced

Get your papers done by pros!

Other Pages

Globin term papers, bourgeois term papers, harmonization term papers, divergence term papers, harlequin term papers, melancholy term papers, idealist term papers, entertainment value college essays, peer reviewed research paper example, free argumentative essay about decline of the american empire since 2003, example of critical thinking on ethical issues in the study, free report on project deliverables 2 business requirements, example of the role of internet and crime research paper, good book review about a visit from the goon squad, the hot zone book reviews examples, sample essay on unemployment, free learning from evan thomas video course work example, dead poets society movie reviews examples, psychological considerations and sociological effects of 3 d printing technology research paper, puzzle image creative writing sample, education in arizona essay examples, respond paper week 3 essay samples, free roles and functions of school nurses course work sample, example of article review on outsourcing, good essay about guidance teaching practice, free research paper about sexual harassment at colleges and universities, good example of the seattle minimum wage case study, la grande essays, humphry davy essays, ocean ridge essays, sacred heart essays, glycation essays, music appreciation essays, globus essays, glycan essays, territorial expansion essays, tribute money essays, the tribute money essays, microblogging essays, honia essays, single thing essays, dugard essays, big man essays.

Password recovery email has been sent to [email protected]

Use your new password to log in

You are not register!

By clicking Register, you agree to our Terms of Service and that you have read our Privacy Policy .

Now you can download documents directly to your device!

Check your email! An email with your password has already been sent to you! Now you can download documents directly to your device.

or Use the QR code to Save this Paper to Your Phone

The sample is NOT original!

Short on a deadline?

Don't waste time. Get help with 11% off using code - GETWOWED

No, thanks! I'm fine with missing my deadline

Toyota TQM: Total Quality Management Theory and Practice

Need to write a case study on TQM? Toyota is a great topic to write about! Toyota total quality management is among the best in the world. Read this paper to learn more!

Literature Review

Case study: toyota tqm, conclusions, recommendations, reference list.

Total quality management (TQM) is a systematic approach to quality assurance that is actively used by companies in various sectors. TQM is largely based on the principle of kaizen, which reflects an organization’s commitment to continuous quality improvement (Kiran 2017). As explained by Kiran (2017), TQM is an organization-wide approach to implementing and maintaining a system of tools to help in controlling and improving the quality of services or products delivered to customers. TQM has gained substantial attention in research, and many companies all over the globe have applied the system. One of the most successful examples of TQM implementation is Toyota, which pioneered the use of TQM in the automobile industry. The present report discusses the methodology and operational framework of TQM based on research and Toyota’s case study, providing recommendations for businesses wishing to adopt TQM.

Tools and Techniques

One of the fundamental notions in literature discussing TQM tools and techniques is the approach to quality measurement. Kiran (2017) states that there are five different approaches to quality measurement, including transcendent, product-based, user-based, manufacturing-based, and value-based. In the transcendent approach, quality is defined subjectively, which makes it difficult to apply this approach to products and services (Kiran 2017). Other four measures evaluate quality objectively based on product characteristics, customer satisfaction, process quality, or cost-efficiency of a product (Kiran 2017). Using one of these approaches makes it easier for companies to define the target quality level and adjust operations as necessary to achieve it consistently.

The key approach in total quality management that allows for achieving and maintaining the desired level of quality is the PDCA cycle which consists of four phases: plan, do, check, and act. The cycle was developed by Edwards Deming, who is considered to be the creator of the TQM method (Kiran 2017). It means that organizations seeking to apply TQM need to examine quality outcomes in each of the four steps of production. At the planning stage, processes are designed in a way to ensure the target level of product quality (Dudin et al. 2015). At the production stage, processes need to be monitored consistently to avoid errors that could impact quality. Quality assurance should be applied to the items or services produced to identify defects, variations, and deviations from the set quality level. Lastly, the final stage is to analyze the reasons for any problems found and apply the cycle again to improve performance (Dudin et al. 2015). This approach to quality management ensures continuous quality improvement, which is the primary principle of TQM.

Another topic of concern in TQM literature is the tools that can be used to analyze problems and achieve meaningful change in processes to improve quality. According to Kiran (2017), TQM uses a scientific approach to problem-solving that involves active support from a company’s human resources. In other words, the TQM approach involves evidence-based tools that employees can apply to provide suggestions for process improvement. These tools include Fault Tree Analysis (FTA), Failure Mode Effect Analysis (FMEA), Reliability Analysis of in-service failure Data (RDA), Fishbone Analysis, and many others (Fragassa, Pavlovic & Massimo 2014). Each of these tools is designed to divide a particular process into stages to identify a particular part of the process, causing a quality problem.

An important tool in TQM is a quality circle, which seeks to find solutions and identify the root cause of failure (Kiran 2017). Quality circles consist of various employees who have valuable knowledge and could apply it to propose and discuss solutions. For example, if there is an issue with supply delays, a quality circle might include supply chain managers, logistics workers, operators, manufacturing managers, team leaders, and other relevant staff members. The use of quality circles is beneficial because employees can provide insight into the issue and offer creative, cost-effective solutions (Kiran 2017). By allowing employees to take part in decision-making and problem-solving, organizations can also enhance their levels of engagement, motivation, and job satisfaction, which would have a positive impact on performance (Alsughayir 2014). This means that the TQM approach is beneficial for continuous improvement in various organizational areas, even when it focuses mostly on manufacturing.

Implementation and Outcomes

Factors affecting the implementation of TQM and its success have also been reviewed by scholars. For example, Obeidat et al. (2016) found that beneficial knowledge management practices had a positive influence on the application and success of TQM tools and techniques in various companies. Hence, companies that apply employee training and organizational learning strategies while also using a consistent approach to building organizational knowledge, such as codification, would benefit more from TQM than those that do not. A different inquiry by Aquilani et al. (2017) highlighted organizational culture and strategy to be crucial success factors in TQM efforts, noting that companies with a strong strategy and a customer-focused culture were more likely to be effective in TQM. Cătălin, Bogdan, and Dimitrie (2014) agreed that culture and strategy play an essential role in TQM efforts while also noting that weak employee commitment, lack of guidance, inefficient process management, bureaucracy, and other factors could also create barriers to TQM implementation.

Finally, research on TQM showed the potential benefits of implementing this system correctly in various industries and organizational contexts. As shown in a study by Ngambi and Nkemkiafu (2015), TQM practices have a direct impact on cost reduction in manufacturing firms. Moreover, increased employee training and empowerment associated with TQM also lead to significant increases in financial performance and corporate social responsibility (Ngambi & Nkemkiafu 2015). Furthermore, research by Mwaniki and Okibo (2014) confirmed that the involvement of top management in quality control and continuous improvement contributed to the financial performance of companies in the banking sector. TQM practices were also found to enhance organizational culture and productivity (Valmohammadi & Roshanzamir 2015). Thus, the successful implementation of TQM can bring many benefits to companies.

Toyota Motor Corporation is a Japanese car manufacturer that produces and sells motor vehicles all over the globe. Its original brand, Toyota is one of the most popular car brands all over the globe, in line with Volkswagen, Ford, Honda, Nissan, Hyundai, and Kia. In 2016, Toyota was the largest car manufacturer in the world by sales volume (Parker 2016). Besides Toyota, the company also produces cards under the brand names Hino, Lexus, and Ranz, which cater to various customer segments. The vehicles produced by Toyota are famous for their high quality and durability, which allows the company to make consistently high profits. This is mainly due to the use of TQM practices, which were implemented by the company back in the 20th century (Toyota Motor Corporation 2012a). The use of TQM has also allowed Toyota to design and establish the Toyota production system, which has been used by many other companies in the manufacturing sector due to its benefits (Amasaka 2014). As will be shown in the case study, TQM practices used by Toyota comply with evidence-based principles and recommendations, which is what enabled them to be extremely effective.

TQM Application

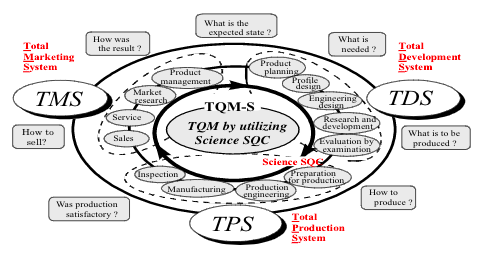

Although TQM in Toyota is focused on increasing the quality and reducing the variability in products, the company applies TQM to all of its activities (Figure 1). These include product planning, profile design, engineering design, research and development, evaluation, production preparation, product engineering, manufacturing, inspection, sales, service, market research, and product management (Amasaka 2014). In the development stage, quality is judged based on examinations of planned performance and characteristics, which allows ensuring the absence of structural or engineering errors (Amasaka 2014). During production-related stages, from preparation to inspection, the quality of processes, materials, individual parts, and final products is monitored based on objective measures (Amasaka 2014). This is essential because for a car to be durable and reliable, quality control has to be applied to every component, from the engine to the paint. A comprehensive and detailed approach to quality at these stages helps to ensure that the company’s products match the consumers’ needs, thus fostering customer satisfaction and loyalty.

Similarly, the sales, service, market research, and product management stages also require quality control in order to improve satisfaction. To achieve this, Toyota conducts regular customer satisfaction surveys and engages customers in quality improvement efforts by allowing them to submit ideas and suggestions, as well as by providing maintenance services after purchase (Amasaka 2014). An essential aspect of quality management in Toyota is that the company uses customers’ claims to identify and address problems. Warranty claim reduction activities and the Dynamic Assurance System (DAS) have been used for this purpose since the 1970s (Toyota Motor Corporation 2012b). All in all, Toyota is an example of best practices in TQM due to how its principles are applied throughout the company.

Best Practices in TQM Toyota

There are four primary characteristics of Toyota’s approach to quality management. First, the company uses quality control and assurance methods that are based on extensive research and testing (Toyota Motor Corporation 2012b). This means that all of the tools applied by Toyota, including FMEA and FTA, proved to be effective through research and experience. Secondly, the company actively engages its employees in the process of quality control by establishing quality circles, conducting training, and performing internal audits (Toyota Motor Corporation 2012b). Thirdly, the application of TQM tools in Toyota is in line with its strategy, which is customer-focused. Toyota Motor Corporation (2012b) states that there are specific committees that are tasked with improving customer centricity on an ongoing basis, including the Customer Delight (CD) Quality Improvement Committee and the Customer Satisfaction (CS) Improvement Committee. Finally, the approach to quality assurance in Toyota is systematic and involves all departments, divisions, and facilities in the company. All of these characteristics are consistent with the definition of TQM and its fundamental methodology. As a result, they address possible barriers to the successful implementation of TQM and allow the company to benefit from the system.

All in all, the present research has achieved its goal of discussing the methodology and operational framework of TQM based on literature and on Toyota’s case study. The literature review provided in-depth information regarding various tools and techniques used in TQM, as well as factors influencing the success of TQM initiatives. The literature review showed that TQM is best used throughout the organization and that it should rely on the company’s definition of quality. This definition, in turn, should be applied to every step of operations using the PDCA cycle, which is at the foundation of TQM (Dudin et al. 2015; Kiran 2017). Research also showed that TQM is a relatively flexible approach to quality improvement because companies can choose techniques and tools that suit their goals, strategy, and operations. This aspect of TQM is vital because it allows applying the framework to any company, regardless of its size, scope, or products.

The thorough review of Toyota’s TQM strategy is also a significant achievement of the work since it shows an example of effective TQM implementation. Toyota has been using TQM for decades to improve product quality and customer satisfaction. The TQM practices in Toyota are useful because the approach to TQM in the company complies with the foundational methodology of TQM. For instance, customer focus, comprehensiveness, and the use of reliable tools are highlighted by Kiran (2017) as the features crucial to successful implementation. Hence, by exploring Toyota’s approach to TQM, the paper discussed best practices in the area, which can be used for quality improvement efforts in various other settings.

The work is significant both to research and to practice. On the one hand, it provides an in-depth exploration of Toyota’s TQM strategy and relates it to the methodology of TQM, thus proving that the theoretical framework proposed in research literature can be successfully applied in practice. The paper also shows the flexibility of TQM methods, which contributes to the literature in the field. Although the flexibility of the TQM approach has been briefly addressed in the literature, there are no recent studies that discuss how companies can use this feature to their advantage. Based on Toyota’s case, it appears that aligning TQM principles with the company’s global strategy helped to produce a working operational framework for implementation.

On the other hand, the work undertaken in the paper can also contribute to practice by providing managers with more insight into TQM implementation. As evident from the literature review, TQM is a rather complex method that has many components, and thus, managers require to apply it carefully to achieve the best results. In particular, it is important to choose the tools that suit the organization’s goals while also removing barriers to successful implementation. Both of these concerns about the TQM application are discussed in the case study and the literature review. Both sections of the paper show that focusing on customer satisfaction as the key desired outcome of the TQM implementation project, as well as engaging employees through shared problem-solving and training, are helpful ways of achieving success.

Moreover, the paper also emphasizes the importance of facilitating organizational learning, creativity, and innovation through discussion boards, such as quality circles or committees. In Toyota’s case, committees perform the function of quality circles because they focus on a particular issue and attempt to find solutions that would help the company to address it at the corporate level. All of these findings can be applied by managers who seek to use the TQM methodology to achieve a significant increase in quality, customer satisfaction, productivity, and cost efficiency.

Overall, there are two key lessons that can be learned from this research report. First of all, it is essential to draw comparisons between literature and practice in the study of various management techniques. The exploration of TQM provided in the paper involves both theoretical and practical perspectives, which contribute to the paper differently. The literature review provides a summary of the topic and highlights critical concerns based on research evidence. For instance, the literature on the barriers to TQM implementation is useful for understanding the relation of the framework to various organizational factors. Since employee resistance, lack of commitment, and poor engagement have a negative influence on TQM, it is obvious that human resources management plays a crucial role in TQM success. Moreover, studies also identify the importance of top management’s involvement in TQM implementation. This means that TQM is also linked both to leadership and to strategy, and thus it should be aligned with other strategic tools used by a company and receive enough support from leaders in the form of information, resources, and guidance.

The case study of effective TQM in Toyota is the ultimate proof of this, and it also suggests more ideas on TQM use. In particular, Toyota’s case highlights the importance of remaining customer-focused as part of continuous quality improvement. The company presents some ways to do it by investigating warranty claims, welcoming suggestions from clients, and creating quality circles (committees) focused on customer satisfaction.

The second lesson is that while there is a substantial volume of research on TQM, scholars have not yet been able to narrow it down into a specific framework due to the flexibility and variability of TQM tools and techniques. While these features are important, they might pose challenges for inexperienced managers who attempt to implement TQM. The best option for managers at the moment is to examine cases of TQM implementation in similar companies, which can help them to design a successful strategy.

Based on the information above, there are two main recommendations for further studies in the area of TQM. Firstly, it is crucial to consider the implementation of TQM from a more practical viewpoint. For example, future research could examine the plans and strategies used by various companies to apply TQM and relate them to financial or quality outcomes. Secondly, it would be beneficial to perform more research using the case study method. As evident from this paper, connecting TQM theory to its applications in large companies can produce results that will be useful for managers. Thus, studies could focus on comparing TQM methodology to the operational frameworks used by other companies practicing TQM successfully.

Alsughayir, A 2014, ‘Does practicing total quality management affect employee job satisfaction in Saudi Arabian organizations?’, European Journal of Business and Management , vol. 6, no. 3, pp. 169-175.

Amasaka, K 2014, ‘New JIT, new management technology principle: surpassing JIT’, Procedia Technology , vol. 16, pp. 1135-1145.

Aquilani, B, Silvestri, C, Ruggieri, A & Gatti, C 2017, ‘A systematic literature review on total quality management critical success factors and the identification of new avenues of research’, The TQM Journal , vol. 29, no. 1, pp. 184-213.

Cătălin, SH, Bogdan, B & Dimitrie, GR 2014, ‘The existing barriers in implementing total quality management’, Annals of the University of Oradea, Economic Science Series , vol. 23, no. 1, pp. 1234-1240.

Dudin, M, Frolova, E, Gryzunova, N, & Shuvalova, E 2015, ‘The Deming Cycle (PDCA) concept as an efficient tool for continuous quality improvement in the agribusiness’, Asian Social Science , vol. 11, no. 1, pp. 239-246.

Fragassa, C, Pavlovic, A & Massimo, S 2014, ‘Using a total quality strategy in a new practical approach for improving the product reliability in automotive industry’, International Journal for Quality Research , vol. 8, no. 3, pp. 297-310.

Kiran, DR 2017, Total quality management: key concepts and case studies , Elsevier, Cambridge, MA.

Ngambi, MT & Nkemkiafu, AG 2015, ‘The impact of total quality management on firm’s organizational performance’, American Journal of Management , vol. 15, no. 4, pp. 69-85.

Mwaniki, C & Okibo, BW 2014, ‘Effects of total quality management on financial performance in the banking sector: a case study of national bank of Kenya’, IOSR Journal of Economics and Finance, vol. 3, no. 2, pp. 34-30.

Obeidat, BY, Hashem, L, Alansari, I, Tarhini, A & Al-Salti, Z 2016, ‘The effect of knowledge management uses on total quality management practices: a theoretical perspective’, Journal of Management and Strategy , vol. 7, no. 4, pp. 18-29.

Parker, J 2016, Overview: all you need to know about Toyota Motor Corporation , Web.

Toyota Motor Corporation 2012a, Changes and innovations (include the Creative Idea Suggestion System) , Web.

Toyota Motor Corporation 2012b, Quality assurance activities , Web.

Valmohammadi, C & Roshanzamir, S 2015, ‘The guidelines of improvement: relations among organizational culture, TQM and performance’, International Journal of Production Economics , vol. 164, pp. 167-178.

Cite this paper

- Chicago (N-B)

- Chicago (A-D)

StudyCorgi. (2021, July 23). Toyota TQM: Total Quality Management Theory and Practice. https://studycorgi.com/toyota-total-quality-management-theory-and-practice/

"Toyota TQM: Total Quality Management Theory and Practice." StudyCorgi , 23 July 2021, studycorgi.com/toyota-total-quality-management-theory-and-practice/.

StudyCorgi . (2021) 'Toyota TQM: Total Quality Management Theory and Practice'. 23 July.

1. StudyCorgi . "Toyota TQM: Total Quality Management Theory and Practice." July 23, 2021. https://studycorgi.com/toyota-total-quality-management-theory-and-practice/.

Bibliography

StudyCorgi . "Toyota TQM: Total Quality Management Theory and Practice." July 23, 2021. https://studycorgi.com/toyota-total-quality-management-theory-and-practice/.

StudyCorgi . 2021. "Toyota TQM: Total Quality Management Theory and Practice." July 23, 2021. https://studycorgi.com/toyota-total-quality-management-theory-and-practice/.

This paper, “Toyota TQM: Total Quality Management Theory and Practice”, was written and voluntary submitted to our free essay database by a straight-A student. Please ensure you properly reference the paper if you're using it to write your assignment.

Before publication, the StudyCorgi editorial team proofread and checked the paper to make sure it meets the highest standards in terms of grammar, punctuation, style, fact accuracy, copyright issues, and inclusive language. Last updated: December 12, 2023 .

If you are the author of this paper and no longer wish to have it published on StudyCorgi, request the removal . Please use the “ Donate your paper ” form to submit an essay.

Pardon Our Interruption

As you were browsing something about your browser made us think you were a bot. There are a few reasons this might happen:

- You've disabled JavaScript in your web browser.

- You're a power user moving through this website with super-human speed.

- You've disabled cookies in your web browser.

- A third-party browser plugin, such as Ghostery or NoScript, is preventing JavaScript from running. Additional information is available in this support article .

To regain access, please make sure that cookies and JavaScript are enabled before reloading the page.

IMAGES

VIDEO

COMMENTS

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business. Get a custom report on Implementation of Total Quality ...

The Toyota Way Model was introduced). 12. Implementation of TQM in Automotive Industry: o Internally, there are four fields of quality management in the Automotive industry: • Sales - directly ...

Save. Summary. Toyota has fared better than many of its competitors in riding out the supply chain disruptions of recent years. But focusing on how Toyota had stockpiled semiconductors and the ...

T oyota Quality System case study. Introduction. T oyota from the early 1960s alongside their supplier network consolidated the way in which. they were able to refine their production system ...

At the heart of Toyota's approach to quality management lies the Toyota Production System (TPS), a set of principles and practices designed to reduce waste and improve efficiency. TPS focuses on two main principles: Jidoka (Automation with a Human Touch): It involves integrating automation with human intervention.

Toyota then adopted "TQC" (Total Quality Control) in 1961 as a further evolution of quality methods. Toyota was awarded the Deming Prize in 1965. They switched from the TQC term to TQM in 1995. I love Toyota's description of "genchi genbutsu" (referenced in Tracey's one post) or the practice of "going to see" at the "gemba" (the ...

Stable and paranoid, systematic and experimental, formal and frank: The success of Toyota, a pathbreaking six-year study reveals, is due as much to its ability to embrace contradictions like these ...

Corporation related to total quality management and business e xcellence derive from the Toyota P roduction S ystem and these practices are to be found in the attributes o f business excellence.

The paper aims to highlight the relationship between the concepts of total quality management and business excellence, and to identify and analyze the best practices related to them at Toyota Motor Corporation, a leader of automotive industry. The information obtained through the direct and personal observation method and from multiple ...

Toyota implemented total quality management (TQM) very successfully. Key aspects of Toyota's TQM approach included: 1) Applying quality management standards throughout the entire organization and across all departments and levels. 2) Focusing on continuous process improvement through kaizen to ensure all processes are measurable, repeatable, and visible. 3) Gaining a strong commitment to ...

Total Quality Management in Toyota - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. Toyota implemented a comprehensive Total Quality Management (TQM) system to improve operations and performance. Key aspects included: 1) Applying quality standards to all business elements and levels to limit barriers and ensure excellent customer/supplier ...

Enhancing Quality Management Practices in Manufacturing: A Case Study of Toyota. International Journal of Research Publication and Reviews, Vol 4, no 12, pp 408-411 December 2023. International Journal of Research Publication and Reviews. Journal homepage: www.ijrpr.com ISSN 2582-7421. Enhancing Quality Management Practices in Manufacturing: A ...

Toyota case study. Usman Zafar ... Total Quality Management (TQM) is a set of management practices followed organization-wide to ensure customer requirements are consistently met or exceeded. It focuses on process measurement, control, and continuous improvement with participation from all organization members to improve processes, products ...

Total. Quality Management in Toyota is entirely based on "Customer First" criterion with an. equal importance to "Continuous Kaizen" and "Total Participation". To achieve these, the automobile giant has formed the following set of principles. 1. Challenge: To set a clear vision for a steady progress and meeting the requirements to ...