10 Innovative Supply Chain Management Project Ideas & Topics For Beginners [2024]

![research project topics for supply chain management 10 Innovative Supply Chain Management Project Ideas & Topics For Beginners [2024]](https://www.upgrad.com/__khugblog-next/image/?url=https%3A%2F%2Fd14b9ctw0m6fid.cloudfront.net%2Fugblog%2Fwp-content%2Fuploads%2F2021%2F02%2F1761.png&w=1920&q=75)

Most post-graduate students pursuing an MBA in Supply Chain Management are left confused when it comes to figuring out what topic they should base their supply chain management projects/theses. The motive of a thesis should be to study the inefficiencies in the supply chain infrastructure and propose solutions to eliminate them.

In this article, we present a list of interesting supply chain management project ideas so you know how you can scope your projects and what concepts you can cover. So let’s start by taking a look at the current market scenario in supply chain management.

What is Supply Chain Management and What is its Significance in the Current Economic Scenario?

Supply Chain Management (SCM) refers to the technique of handling a string of operations involved in the transportation of raw materials from the source to an enterprise to develop a desired product or service, which will eventually be delivered to its intended customer.

A properly functioning supply chain is crucial to the development and growth of any country. It gives countries a competitive edge over others in the marketplace. Supply chain management is aimed at cutting down costs, maximizing efficiency, and increasing productivity.

Disruptions in the supply chain in COVID-hit 2020 had far-reaching impacts on almost all sectors in India. It brought down the year-over-year rate in India to 4.5%.

As India recovers from this stumbling block, active efforts will be needed to repair the damage done to the supply chain infrastructure. Thankfully, India is already on the path to digitizing the supply chains. The current Indian scenario would benefit greatly from employing effective strategies to enhance the productivity of the supply chain and this depends on supply chain management to a great extent.

To strike a fruitful balance between supply and demand, supply chain management must join hands with technology to improve supply chain processes and provide solutions to eliminate existing supply chain constraints.

Our Learners also read: Communication skills course online free !

What are the Major Challenges in Supply Chain Management Today? How Can you Overcome Them?

Supply Chain Management is one of the more unpredictable professions out there and there is a diverse range of challenges the industry faces.

However, the most significant areas that require attention are:

- Inadequacy in Managing Unprecedented Delays — Delays are but a part of supply chains since there are many variable factors in play. But there are counter-strategies that companies can implement to avoid frequent delays. Using warehouse management software can help keep track of the timelines of delivery, shortage in stocks, and scheduled arrivals of shipments. In this manner, a company can time arrivals and deliveries so any replenishing can be done before stocks run out.

- Failing to Keep up with the Fast-Changing Market — There’s no way around changing times. The best a company can do is encourage more flexibility in its operations and use logistics management software to adapt to the fast-changing world.

- Inadequate Steps Being taken to Manage Risks — Investing in logistics management can help stay on top of disruptions in management. With risks, preparation is key.

- Increased Costs — Financial qualms have resulted in increased rates of raw materials and goods. For this reason, the entire supply chain suffers. A company needs to have strict cost control measures in place to combat these issues. More efficiency should be promoted in warehouse and logistics management.

- Lack of Solutions to Improve Customer Service Quality — Customizability is the need of the hour. To provide quality services to customers, businesses should join hands with new and emerging technologies.

- Shortage of Skilled Personnel — Thanks to COVID, there is an increased requirement of individuals in supply chain management. This has also led to an increase in the market value of people working in this field. A lot of people now are keen to pursue a career in the supply chain industry. It is not without reason though. Supply chain management makes for a lucrative career option with regards to the advancement opportunities it offers and the wide range of industries that are looking to hire. This includes retail, transportation, food and beverages, healthcare, hospitality, and Information Technology, to name a few.

Read : Essential management skills for a successful career

8 Interesting Supply Chain Management Projects

Since there is a requirement of actionable strategies and innovative solutions for improving supply chain management in almost every industry, there is a growing demand for impressionable officials in SCM. Therefore, opting for a career in SCM will likely prove to be an exceptionally rewarding choice.

For those who have already entered the field, the onus is on them to positively impact worldwide trends by devising strategies and ideas through creative thinking and analysis, to strengthen the supply chain management infrastructure.

For that reason, we have listed some interesting Supply Chain Management project ideas you can consider that will help streamline significant problems in the industry today.

Read : Product manager career path and its scope

1. Demand Planning and Forecasting

This project is aimed at strategizing a cost-effective solution to maintain sustainability in supply chains. With efficient demand planning using Demand Caster and forecasting the increases in price in the future, businesses can increase Purchase Price Variance (PPV) savings. For better management of the inventory, the project proposes that supply chain organizations integrate Inventory Optimization SaaS into their operations.

2. Developing Productive Supplier Relationships in a Competitive Market

The project highlights the significance of developing and maintaining productive relationships with suppliers in a fast-changing, supply chain market. The study explores the critical factors that impact the quality of such relationships, and what steps a company can take to improve and foster mutually beneficial relationships with suppliers, thereby, enhancing the process of purchase management.

3. WMS Systems Consolidation

The project proposes that more than one Warehouse Management System (WMS) system be consolidated to one system that is hosted centrally. This will enhance the adaptability of WMS systems to catch up with evolving trends in businesses. Since processes are now automated, it can reduce Total Cost of Ownership (TCO) by using RF devices to track product movement. It also gives managers enhanced visibility to effectively handle processes around a warehouse.

This automation can be made possible by using:

- HighJump Software WMS

- HighJump’s Web-based reporting system, and

- HighJump WebWise

4. Effective Negotiating Practices to Reduce Costs

This project explores the importance of strong negotiation and persuasion skills to save a company a significant amount of money while purchasing raw materials. It proposes that every supply chain management official must undergo professional training to be able to effectively use negotiation as a tool to reduce expenditures for a company.

5. Rethinking the Workflow in Manufacturing

The project proposes reorganizing the workflow of individual technicians in manufacturing to improve the productivity of a manufacturing company. It can be made possible by employing Demand Solutions to encourage planning and scheduling in advance. This will result in improved stocking, builder efficiency, and advanced visibility of orders to optimize internal operations accordingly.

6. Big Data and IoT in Supply Chain

The project emphasizes the role of Big Data in optimizing supply chain operations and improving performance efficiency through effective prediction. Companies implementing Big Data and IoT in their business are not just able to proactively manage risks but also increase the overall revenue in sales.

As per Gartner’s research , “IoT and big data are knitted together. The IoT drives big data, providing more information, from several different sources in real-time, and allows us to gain completely new perspectives on the environment around us.”

The project proposes that the significance of these two technologies in improving efficiency is undeniable and companies will increasingly adapt to these standards by restructuring their business processes.

7. Computerized Inventory Control

The project highlights the importance and effective use of computers in inventory control to enhance business processes. It also discusses methodologies, analysis techniques, and testing methods to ensure the accuracy and effectiveness of computerization in a business environment.

Read: Boost your product manager career by joining the management program from IMT Ghaziabad.

8. Artificial Intelligence and Machine Learning in Supply chain

The project proposes that companies must adapt Artificial Intelligence to improve decision-making activities in an organization. Since AI-based machines are designed to identify patterns, learn, and analyze information in a manner that mimics human intelligence, they prove to be effective decision-making tools. The study proposes that businesses must take a keen interest in recognizing areas where the application of AI and Machine Learning can prove productive to reap the widespread benefits of these technologies.

Here are some other significant supply chain topics for your project:

- Supply Chain Management: Ethical and Social Practices

- The role of government initiatives in supply chain management transformation

- The importance of Agile Methodologies in supply chain management

- The impact of Demand Driven Material Requirements Planning (DDMRP)

- E-logistics in Supply Chain Operations

- The future scope of supply chain management in India

- Detailed Review of Supply Chain as a Service (SCAAS)

- SaaS, IaaS & PaaS: Cloud-specific supply chain management

- Use of Robotics and Automation in supply chain management

- Enterprise Resource Planning (ERP) and Supply Chain Management (SCM)

Read : Product management career path and its scope

9. The IoT-Based Inventory Management:

This project focuses on integrating sensors and connected devices across various companies’ supply chains. This implementation provides real-time, precise data on stock levels and warehouse conditions, facilitating efficient tracking of product movement from production to consumption. By leveraging this technology, companies can enhance stock accuracy and make proactive decisions regarding inventory management. This includes optimizing the reordering process, minimizing stockouts, and reducing excess inventory. Ultimately, implementing an IoT-based inventory management system leads to a streamlined and optimized supply chain, benefiting companies by improving operational efficiency and reducing costs.

10. Supply Chain Risk Management System:

Creating a robust Supply Chain Risk Management (SCRM) System is a crucial project for professionals in the supply chain field. This project emphasizes the importance of advanced software solutions, providing students with hands-on experience. The software integrates real-time data, predictive analytics, and machine learning algorithms. These features empower companies to identify and assess risks effectively, enabling them to develop proactive solutions. A SCRM system addresses various disruptions, such as natural disasters, geopolitical events, and economic instabilities, ensuring the resilience of supply chains. By implementing this system, companies can mitigate potential disruptions and maintain continuity in their operations.

The above-listed topics include some of the most trending subjects in the field of supply change management. They are aimed at identifying inefficiencies and improving supply chain practices to boost the growth of the Indian economy. We hope this gave you an idea of what your project can be based on. The best way to capitalize on this opportunity is to enroll in a certification program such as upGrad’s Global Master Certificate in Integrated Supply Chain Management .

The course is completely delivered online. Considering that MSU ranks #1 in supply chain management , students get the exclusive opportunity to learn from top mentors and instructors in the field. What’s more is that they enjoy many other perks like live learning & interaction sessions, 360-degree career assistance, interactive quizzes, case studies, interview preparation, resume feedback, and career counseling.

Learn Supply Chain Analytics Courses online from the World’s top Universities. Earn Masters, Executive PGP, or Advanced Certificate Programs to fast-track your career.

Sandeep Pereira

Something went wrong

Related Programs View All

Certification

16 Hrs Live Expert-Led Sessions

14 Case Studies, 3 Mock Tests

View Program

Master's Degree

Dual Credentials

Job Assistance

16+ Hrs Expert-Led Sessions

5 Simulation Exams, 8 Mock Tests

24 Hrs Live Expert-Led Training

Earn 24 PDUs and 24 SEUs

36 Hrs Live Expert-Led Training

Premium 2000+ Question Bank

32 Hrs Live Expert-Led Training

Earn 32 PDUs and SEUs

Complimentary On-Demand Course

1 Year SAFe® Community Membership

88 Hours On-Demand Learning

100% Exam-Pass Guarantee

16 Hrs Live Expert-Led Training

Earn 16 PDUs and 16 SEUs

AACSB accredited

Training by Top-Notch SPCs

3 Day Leadership Summit in Dubai

Ivy League School

Executive PG Program

Offline Campus Experience

PG Certification

6-10.5 Months

2500+ Students Enrolled

EQUIS & AMBA Accredited

Executive Coaching

Simulations, 5 Mock Tests

Instructor Led Model

16-Hrs Live Expert-Led Sessions

Earn 16 SEUs and 16 PDUs

16+ Hrs Expert-Led Training

AMBA, AACSB & NIRF Accreditation

24+ Hrs Expert-Led Sessions

Simulation Exams, 24 PDUs

35 Hrs Live Expert-Led Training

35 PD Hrs, 35 CDUs & 35 PDUs

24-Hrs Live Expert-Led Sessions

Activities and Case Studies

8+ Hrs Expert-Led Sessions

Interactive Sessions, Activities

36+ Expert-Led Training

5 Simulation Exams, Projects

21 Hrs Live Expert-Led Training

Earn 21 CDUs and 21 PDUs

2-Day Live Expert-led Training

Simulations, 4 Mock Tests

16 Hours of Instructor-Led Sessions

Simulation Exams and Mock Tests

Earn 16 PDUs and 16 SEUs

24-Hrs Live Expert-Led Training

Earn 24 SEUs and 24 PDUs

Explore Free Courses

Learn more about the education system, top universities, entrance tests, course information, and employment opportunities in Canada through this course.

Advance your career in the field of marketing with Industry relevant free courses

Build your foundation in one of the hottest industry of the 21st century

Master industry-relevant skills that are required to become a leader and drive organizational success

Build essential technical skills to move forward in your career in these evolving times

Get insights from industry leaders and career counselors and learn how to stay ahead in your career

Kickstart your career in law by building a solid foundation with these relevant free courses.

Stay ahead of the curve and upskill yourself on Generative AI and ChatGPT

Build your confidence by learning essential soft skills to help you become an Industry ready professional.

Learn more about the education system, top universities, entrance tests, course information, and employment opportunities in USA through this course.

Suggested Blogs

by Shashank Jain

27 Feb 2024

![research project topics for supply chain management 44 Most Common Supply Chain Management Interview Questions & Answers [For Freshers & Experienced]](https://www.upgrad.com/__khugblog-next/image/?url=https%3A%2F%2Fd14b9ctw0m6fid.cloudfront.net%2Fugblog%2Fwp-content%2Fuploads%2F2021%2F01%2F1767.png&w=3840&q=75)

by Sandeep Pereira

19 Feb 2024

![research project topics for supply chain management Supply Chain Management Salary in India in 2023 [For Freshers & Experienced]](https://www.upgrad.com/__khugblog-next/image/?url=https%3A%2F%2Fd14b9ctw0m6fid.cloudfront.net%2Fugblog%2Fwp-content%2Fuploads%2F2021%2F01%2F1762.png&w=3840&q=75)

18 Feb 2024

29 Jun 2023

by Keerthi Shivakumar

27 Jun 2023

26 Sep 2022

Alert: Beware of 'Globly' misleadingly associated with NimbusPost. Stay vigilant.

8 Innovative Supply Chain Management Project Ideas & Topics For Beginners

by Deepika. | Nov 29, 2022 | Domestic Shipping , Supply Chain

When most people think of supply chain management, they envision a stockroom manager who processes inventory and deals with vendors. Sure, the role of a stockroom manager is vital in any company that sells products, but SCM goes beyond just managing warehouse inventory. In today’s digital world, supply chain management is a field that touches almost every part of the business world. As a result, everyone has a stake in how well the supply chain runs, from manufacturers to wholesalers and sellers.

The challenge is coming up with supply chain management project ideas that are unique and innovative. Whether you are looking to advance your career or learn new skills as a hobby, learning how to implement supply chain management projects is not easy. However, with the right information and resources, it isn’t as difficult as you might think.

Here are some tips on how to master the art of SCM and implement innovative supply chain management project ideas in your work or home life.

What is the SCM project?

An SCM ( supply chain management ) project is a collaborative effort to implement new methods or processes to streamline the supply chain. As a result, it increases efficiency, streamlines workflow, and reduces costs.

These initiatives require in-depth research before beginning so that they are implemented successfully and with minimal setbacks. They often have a specific goal or outcome, such as reducing inventory, increasing customer satisfaction, or reducing costs. These projects may last for several months and involve extensive planning and research. There are many different types of SCM projects that an organization may choose from when beginning its initiative. Each type of SCM project has its challenges and best practices.

A successful supply chain management implementation involves:

- Obtaining buy-in from all relevant stakeholders

- Creating an implementation plan

- Developing metrics for success

- Establishing a formal review process post-implementation

Recent Trends in Supply Chain Management

Supply chain resilience.

Supply chain reliance is in the buzz post-pandemic. eCommerce businesses and SMBs have learned the need to mitigate disruption and limit the adversities of unforeseen disasters for businesses. Therefore, businesses will need supply diversification, finding alternatives, agile solutions, and reliable data to bring resilience.

Advanced analytics and automation

The pursuit of robotics, big data, AI, and predictive and prescriptive analytics by businesses will have broad-reaching effects. Traditionally, there were loopholes and a lack of efficiency in the supply chain resulting in high costs, late deliveries, etc. Automation brings high transparency and efficiency to the process.

Internet of Things

The internet of things (IoT) is a digital network of physical objects powered by a wireless network that is connected and accessible at the fingertips. The concept of IoT is already widely used in the supply chain, mainly in logistics, and is expected to continue. For example, IoT is used in inventory management , fleet tracking, and warehouse management, pointing.

Increased visibility

Traditionally, businesses fail to pinpoint the inefficiency within the supply chain causing unsatisfied customers. Tracking and visibility in the supply chain are crucial. It helps identify the loopholes and areas to improve and understand the process’s bits.

Customer centricity

Currently, we’re experiencing a trend where businesses are turning customer-centric from profit-centric. Finally, we understand the meaning of ‘customer is king. This is because customers have too many options and high CAC. Building a supply chain that will enable fast last-mile delivery to the customers will be an equation to crack for businesses.

Use of artificial intelligence

Artificial intelligence is used to build smart warehouses , automate the fulfillment process , and reduce human error. Combining human and artificial intelligence is the key to technology-led innovation in supply chain management.

What are the topics in supply chain management?

Inventory management.

Inventory management is a hot topic in supply chain management than ever before, as customers demand the product available at the moment. Inventory management is the strategic practice of having the right amount of inventory available to meet the demand of customers in the present as well as in the future.

Sustainability

Recent studies show alarming data that negatively impact our environment. If we could do anything to save our existence, now is the time. To reduce carbon footprints, businesses are claiming certain sustainability standards. Their supply chain is uniquely positioned in it, as the logistics sector is the prime contributor to greenhouse gas emissions. Executives are trying to achieve supply chain sustainability through cloud technology and automation .

Risk management

In recent years, businesses have been bombarded with unforeseen disruptions leading to business vulnerability and fragmented supply chains. The lack of a robust supply chain risk management process puts businesses at high operational expenses. Therefore, rather than admiring difficulties, tackling them with a structured process and addressing known risks is the way to achieve supply chain resilience and risk management.

Enterprise resource planning

Companies utilize ERP in planning and managing current and future uncertainties. As a result, the global enterprise resource planning market revenue is on track to hit $78.4 billion by 2026 . The ERP platform encompasses inventory management, manufacturing, logistics, sourcing and procurement, and all other company businesses.

What are the 7 Rs of the supply chain?

Right product.

The supply chain manager must know which market is flourishing and which is declining, as demand is equally proportional to supply chain management. Therefore, identifying which product is in demand and its sustainability is the basis of the supply chain.

Right place

The right product must be sent to the right place. Identifying the right consumer market for your product is another important factor in a supply chain. The supply chain manager must develop an efficient logistics network that enables last-mile delivery to the market and also get a response from the market towards your product.

Right price

Pricing of a product could make or break a product’s sale. The right product price is what customers do not hesitate to spend and incur profits for the company. Therefore, you should execute thorough market research, identify consumers’ capacity for expenditures, and check competitors’ pricing to set the right price for your product.

Right customers

It is the most important ‘R’ in a supply chain. Identifying the right customers is fundamental to any business. Before launching the product, know your customers first, and identify their preferences, age group, purchasing power, and expectations for the success of your product.

Right conditions

Give utmost importance that your product should be delivered to the customers in the right conditions. Delivering faulty products breaks customers’ trust in your brand, which is hard to regain. Use reliable logistic carriers who assure the safe delivery of your products to customers.

The attention span of people is less than a goldfish. Customers want their products fast, and they tend to pay extra for them. Last-mile delivery of products to customers builds trust and long-term relationships. Therefore, a logistics process is necessary to deliver products in real-time.

Right quantity

Keeping the right quantity of products reduces management costs and other expenses. In addition, inventory management in the supply chain helps forecast demand and bring efficiency to the supply chain.

Eight Key Supply Chain Process

Customer relationship management.

Identifying the customers creates value for the supply chain, which is the first and essential part of supply chain management. In this process, the right customers are identified for the product, and their demands and preferences are satisfied by the product.

Supplier relationship management

Nurturing the relationship with suppliers is as important as relationships with customers. A healthy relationship with suppliers is a win-win situation for both the supplier and the business. First, it is identifying the right supplier who delivers products according to your specifications and on time. A good relationship with suppliers enables continuous supply delivery even in a crisis.

Customer service management

Customer service management sounds similar, but it is different from customer relationship management– the process of acquiring customers. Customer service management focuses on interacting with customers and solving and upscaling their experiences with the product. It looks like customer support, giving discounts, etc.

Demand management

Product demand management in the supply chain answers to how much product needs to be produced. Staying updated with the demand for your products in the market helps reduce unwanted expenses in the business. Demand management acts as a thin line that brings efficiency to the supply chain. If the product production is less and the demand is high, you are missing the opportunity to increase profits. Similarly, if the product production is inflated than the demand, your business will incur the high cost of inventory management, warehouse management, logistics, etc.

Order fulfillment

Order fulfillment is the path between supplier level and warehousing to the customer’s doorstep. It starts with receiving a purchase order from the customer, packaging it, and delivering it to the customer. The gravity of quick fulfillment has risen in recent years because customers want their orders just in time.

Manufacturing flow management

It is managing all the activities that enable the movement of products through the manufacturing plant and managing flexibility in the supply chain.

Product development and commercialization

This process of supply chain management includes market research and identifying the unfulfilled demand of the customers for the development of new products and advertising it. Product development and commercialization enable a seamless flow of new products from suppliers to the end customer.

Return management

Return management covers reverse logistics, gatekeeping, product returns, and other activities related to returns. The goal is to identify the loopholes in the process causing returns and successfully control them to reduce the return rate.

- Courier Charges

- Courier Partner

- Courier Service

- Domestic Shipping

- DropShipping

- E-commerce Delivery

- Global Shipping

- Hyperlocal Delivery

- Shipping Aggregator

- Supply Chain

- Warehouse & Fulfillment

Get the latest information on all events, sales, and offers in your inbox directly.

Oops! You are missing out on an exclusive offer.

Get flat ₹500 cashback on first wallet recharge of ₹500.

Offer valid for new users only. By submitting your contact details, you agree to NimbusPost’s Terms and User Privacy Statement.

Please leave this field empty.

At the MIT Center for Transportation & Logistics

- Center for Latin-American Logistics Innovation

- Luxembourg Center for Logistics and Supply Chain Management

- Malaysia Institute for Supply Chain Innovation

- MIT Center for Transportation & Logistics

- Ningbo China Institute for Supply Chain Innovation

- Zaragoza Logistics Center

- Master's Degree Programs

- GCLOG Certificate

- Master's Program Admissions

- Researchers

- Alumni Benefits & SCALE Credentials

Supply Chain and Logistics Research and Reports

The MIT Global Supply Chain and Logistics Excellence (SCALE) Network strives to develop and disseminate supply chain expertise around the world. Our researchers work on projects/problems across the full spectrum of supply chain, including:

- How artificial intelligence and machine learning are impacting supply chain management

- How transportation and freight are changing in a global marketplace

- The promises and pitfalls of Blockchain for supply chain and beyond

- Understanding how companies and organizations manage supply chain risk and build resiliency

- Developments in logistics and strategy for the worlds vulnerable populations

- How digitalization is reshaping supply chains and how these changes impact organizations

- How supply chain consumer models are changing in an increasingly complex retail landscape

- How companies and organizations manage supply chain risk and build resiliency

- Managing sustainability in a competitive global landscape

Learn about our Centers' research and projects on their web sites:

No. 1 in supply chain

U.S. News & World Report ’s 2024 Best Business Schools ranking places the Broad College at No. 1 for graduate supply chain/logistics programs for eight consecutive years. See the numbers .

Areas of Research

- Students & Placements

- (517) 355-2241

- [email protected]

Students in the logistics doctoral program at Broad work closely with faculty from the onset of their program to ensure the best preparation for academic life – including working on supply chain management research projects that eventually lead to publications in top-tier academic journals. The program links the traditional areas of logistics research and development with faculty expertise in the areas of demand management and forecasting, logistics operations and modeling, logistics strategy and relationship management. Both empirical and analytical methods are examined in the program to provide students with the skill sets necessary to succeed in their chosen stream of research.

Publications

Below are selected publications by faculty who work in the logistics doctoral program.

Stanley E. Griffis

2016 Curt B. Moore, G. Tyge Payne, Chad W. Autry, Stanley E. Griffis . (2016) “Project Complexity and Bonding Social Capital in Network Organizations.” Group & Organization Management . May, 1-35. 2015 Bell, John E. Autry, Chad W., Griffis, Stanley E., (2015) “Supply Chain Interdiction as a Competitive Weapon.” Transportation Journal . 54(1), 89-103. 2014 Griffis, Stanley E., Autry, Chad W., Thornton, LaDonna M., ben Brik, Anis (2014) “Assessing Antecedents of Socially Responsible Supplier Selection in Three Global Supply Chain Contexts.” Decision Sciences . 45(6), 1187-1215. Melnyk, Steven, Zobel, Christopher W., Macdonald, John, Griffis, Stanley E. (2014) “Making Sense of Transient Responses in Simulation Studies.” International Journal of Production Research . 52(3), 617-632, 2013 Whipple, Judith M., Griffis, Stanley E., and Daugherty, Patricia J. (2013) “Conceptualizations of Trust: Can We Trust Them?” Journal of Business Logistics . 34(2), 117-130 . Fleming, Christopher L., Griffis, Stanley E ., Bell, John E. (2013) “The Effects of Triangle Inequality on the Vehicle Routing Problem.” European Journal of Operations Research . 224(1):1-7. 2012 Griffis, Stanley E ., Rao, Shashank, Goldsby, Thomas J., Voorhees, Clay M., Iyengar, Deepak, (2012) “Linking Order Fulfillment Performance to Referrals in Online Retailing: An Empirical Analysis.” Journal of Business Logistics . 33(4), 278-292. Griffis, Stanley E ., Whipple, Judith, M., (2012) “A Comprehensive Risk Assessment and Evaluation Model: Proposing a Risk Priority Continuum.” Transportation Journal . 51 (4), 428-451. Porterfield, Tobin E., Macdonald, John R., Griffis, Stanley E ., (2012) “An Exploration of the Relational Effects of Supply Chain Disruptions.” Transportation Journal . 51 (4), 399-427. Griffis, Stanley E ., Bell, John E., Closs, David J., (2012) “Metaheuristics in Logistics and Supply Chain Management.” Journal of Business Logistics. 33(2), 90-105. Griffis, Stanley E ., Rao, Shashank, Goldsby, Thomas J., Niranjan, Tarikere T., (2012) “The Customer Consequences of Returns in Online Retailing: An Empirical Analysis.” Journal of Operations Management . 30 (4), 282-294. 2011 Rao, Shashank, Griffis, Stanley E., Goldsby, Thomas J. (2011) “Failure to Deliver? Linking Online Order Fulfillment Glitches with Future Purchase Behavior.” Journal of Operations Management . 29 (7-8), pp 693-703. Rao, Shashank, Goldsby, Thomas J., Griffis, Stanley E., Iyengar, Deepak (2011) “Electronic Logistics Service Quality (e-LSQ): Its Impact on the Customer’s Purchase Satisfaction and Retention.” Journal of Business Logistics . 32 (2), pp. 167-179. Payne, G. Tyge, Moore, Curt B., Griffis, Stanley E ., Autry, Chad W. (2011) “Multilevel Challenges and Opportunities in Social Capital Research.” Journal of Management . 37 (2), 491-520. Wilcox, William, Horvath, Philip A., Griffis, Stanley E. , Autry, Chad W. (2011) “A Markov Model of Liquidity Effects in Reverse Logistics Processes: The Effects of Random Volume and Passage.” International Journal of Production Economics . 129 (1), 86-101. Bell, John E., Griffis, Stanley E . Cunningham, William J., Eberlan, Jon (2011) “Location Optimization of Strategic Alert Sites for Homeland Defense.” Omega, The International Journal of Management Science. 39 (2), 151-158. 2010 Bell, John E and Stanley E. Griffis (2010), “Swarm Intelligence: Application of the Ant Colony Optimization Algorithm to Logistics-Oriented Vehicle Routing Problems.” Journal of Business Logistics. 31 (2), 157-175. 2008 Autry, Chad W., Stanley E. Griffis (2008), “Supply Chain Capital: The Impact of Structural and Relational Linkages on Firm Execution and Innovation.” Journal of Business Logistics. 29 (1), 157-173. 2007 Griffis, Stanley E ., Thomas J. Goldsby, Martha C. Cooper, and David J. Closs (2007), “Aligning Logistics Performance Measures to the Information Needs of the Firm.” Journal of Business Logistics. 28 (2), 35-56. 2006 Goldsby, Thomas J., Stanley E. Griffis and Anthony S. Roath (2006), “Modeling Lean, Agile, and Leagile Supply Chain Strategies.” Journal of Business Logistics. 27 (1), 57-80. Winner – The Bernard J. LaLonde Award for Best Paper in JBL 2006. 2005 Autry, Chad W., and Stanley E. Griffis (2005), “A Social Anthropology of Logistics Research: Exploring Productivity and Collaboration in an Emerging Science.” Transportation Journal. 44 (4), 27-43. Autry, Chad W., Stanley E. Griffis , Thomas J. Goldsby, L. Michelle Bobbitt (2005), “Warehouse Management Systems: An Initial Assessment, Empirical Analysis and Research Agenda.” Journal of Business Logistics. 26 (2), 165-183. 2004 Griffis, Stanley , Martha C. Cooper, Thomas J. Goldsby and David J. Closs (2004), “Performance Measurement: Measure Selection Based Upon Firm Goals and Information Reporting Needs.” Journal of Business Logistics. 25 (2), 95-118. 2003 Griffis, Stanley E ., Thomas J. Goldsby, and Martha C. Cooper (2003), “Web-Based and Mail Surveys: A Comparison of Response, Data and Cost.” Journal of Business Logistics. 24 (2), 237-258.

Stanley Lim

2022 Lim, S.F.W.T., Richards, T.J., Rabinovich, E. and Choi, M. 2022. Scan based trading and bargaining equilibrium: A structural estimation of supply chain profit. Manufacturing & Service Operations Management, forthcoming. 2021 Lim, S.F.W.T., Gao, F. and Tan, T.F. 2021. Slow and steady, or fast and furious? An empirical study about omnichannel demand sensitivity to fulfillment lead time. Management Science (Major revision). Lim, S.F.W.T., Rabinovich, E., Lee, S. and Park, S. 2021. Estimating stockout costs and optimal stockout rates to improve the management of ugly produce inventory. Management Science (Major revision). Lim, S.F.W.T., Rabinovich, E., Park, S. and Hwang, M. 2021. Shopping activity at warehouse club stores and its competitive and network density implications. Production and Operations Management, 30(1): 28-46. 2019 Lim, S.F.W.T. and Winkenbach, M. 2019. Configuring the last-mile in business-to-consumer e-retailing. California Management Review, 61(2): 132-154.

Jason W. Miller

2017 Miller, J. W . 2017. “Discrete Time Hazard Modeling of Large Motor Carriers’ Longitudinal CSA Performance.” Transportation Journal . Forthcoming. Miller, J. W . 2017. “A Multivariate Time Series Analysis of Motor Carrier Safety Behaviors.” Journal of Business Logistics. Miller, J. W. & Saldanha, J. P. 2017. “Do New Entrants Become Safer over Time?” Transportation Journal. Miller, J. W ., Saldanha, J. P., Rungtusanatham, M., & Knemeyer, A. M. 2017. “How Does Driver Turnover Affect Motor Carrier Safety Performance and What Can Managers Do About It?” Journal of Business Logistics. Miller, J. W ., Golicic, S., & Fugate, B. 2017. “Developing and Testing a Dynamic Theory of Motor Carrier Safety?” Journal of Business Logistics. In Press. Davis-Sramek, B., Fugate, B. S, Miller, J. W , Germain, R., Izyumov, A., & Krotov, K. 2017. “Understanding the Present by Examining the Past: Imprinting Effects on Supply Chain Outsourcing in a Transition Economy.” Journal of Supply Chain Management. 53(1): 65–86. 2016 Miller, J. W ., Fugate, B., & Golicic, S. 2016. “How Organizations Respond to Information Disclosure: Testing Alternative Longitudinal Performance Trajectories.” Academy of Management Journal . In Press. Miller, J. W ., & Saldanha, J. P. 2016. “A New Look at the Relationship between Financial Performance and Safety: A Longitudinal Growth Perspective.” Journal of Business Logistics 37(3): 284–306. Schwieterman, M. A., Miller, J. W . 2016. “Factor Market Rivalry: Towards an Integrated Understanding of Firm Action.” Transportation Journal . 55(2): 97–123. 2015 Mellat-Parast, M., Golmohammadi, D., McFadden, K., Miller, J. W . 2015. “Linking Business Strategy to Service Failures and Financial Performance: Empirical Evidence from the U.S. Domestic Airline Industry.” Journal of Operations Management . 38(1): 14–24. Stromeyer, W. R., Miller, J. W ., Murthy, R., & DeMartino, R. 2015. “The Prowess and Pitfalls of Bayesian Structural Equation Modeling: Important Considerations for Management Research.” Journal of Management . 41(2): 491–520. 2014 Rungtusanatham, M., Miller, J. W ., & Boyer, K. K. 2014. “Theorizing, Testing and Concluding for Mediation in SCM Research: What to Do, What Not to Do.” Journal of Operations Management. 32(3): 99–113. Saldanha, J. P., Miller, J. W ., Hunt, C. S. & Mello, J. E. 2014. “Linking Formal Controls to Motor Carrier Performance: Curvilinear and Interaction Effects.” Transportation Research Part E . 64(1): 28–47. Fawcett, S. E., Waller, M. A., Miller, J. W ., Schwieterman, M. A., Hazen, B. T., & Overstreet, R. E. 2014. “Editorial: A Trail Guide to Publishing Success: Tips on Writing Influential Conceptual, Qualitative and Survey Research.” Journal of Business Logistics . 35(1): 1–16. 2013 Miller, J. W ., Saldanha, J. P., Hunt, S., & Mello, J. E. 2013. “Combining Formal Controls to Improve Firm Performance.” Journal of Business Logistics . 34(4): 301–318.. Miller, J. W ., Stromeyer, W. R., & Schwieterman, M. A. 2013. “Extensions of the Johnson-Neyman Technique to Linear Models with Curvilinear Effects: Derivations and Analytical Tools.” Multivariate Behavioral Research . 48(2): 267-300. Goldsby, T. J., Knemeyer, A. M., Miller, J. W ., & Wallenburg, C. M. 2013. “Measurement and Moderation: Finding the Boundary Conditions in Logistics and Supply Chain Research.” Journal of Business Logistics . 34(2): 109–116.

Judith M. Whipple

2016 Roh, Joseph, Virpi Turkulainen, Judith M. Whipple , and Morgan Swink (forthcoming), “Understanding the Organizational Change Process for Supply Chain Management Organizations.” International Journal of Logistics Management. 2015 Whipple, Judith M ., Robert Wiedmer, and Kenneth K. Boyer (2015), “A Dyadic Investigation of Collaborative Competence, Social Capital and Performance in Buyer-Supplier Relationships.” Journal of Supply Chain Management. 51(2): 3-21 . 2013 Whipple, Judith M ., Stanley Griffis, and Patricia J. Daugherty (2013), “Conceptualizations of Trust: Can We Trust Them?” Journal of Business Logistics. 34:2, 117-130. Roh, Joseph, Judith M. Whipple , Kenneth K. Boyer (2013), “The Effect of Single Rater Bias in Multi-Stakeholder Research: A Methodological Evaluation of Buyer-Supplier Relationships.” Production and Operations Management Journal. 22:3, 711-725 . 2012 Griffis, Stanley and Judith M. Whipple (2012), “A Comprehensive Risk Assessment and Evaluation Model: Proposing a Risk Priority Continuum.” Transportation Journal. 51:4, 428-451 . 2011 Nyaga, Gilbert and Judith M. Whipple (2011), “Relationship Quality and Performance Outcomes: Achieving a Competitive Advantage.” Journal of Business Logistics. 32:4, 345-360. Speier, Cheri, Judith M. Whipple , David J. Closs and M. Douglas Voss (2011), “Global Supply Chain Design Considerations: Mitigating Product Safety and Security Risks.” Journal of Operations Management. 29:7-8, 721-736. Winner, JOM Jack Meredith Best Paper of the Year Award and Stan Hardy Award. Allaway, Arthur W., Patricia Huddleston, Judith M. Whipple , and Alexander E. Ellinger (2011), “Customer-Based Brand Equity, Equity Drivers and Customer Loyalty in the Supermarket Industry.” The Journal of Product and Brand Management. 20:3, 190-204. 2010 Whipple, Judith M. and Joseph Roh (2010), “Quality Fade and Agency Theory in Buyer-Supplier Relationships.” The International Journal of Logistics Management. 21:3, 338-352. Richey, R. Glenn, Anthony S. Roath, Judith M. Whipple , and Stanley E. Fawcett (2010), “Exploring a Governance Theory of Supply Chain Management: Barriers and Facilitators to Integration.” Journal of Business Logistics. 31:1, 237-256 . Bernard J. La Londe Best Paper Award in the Journal – 2010. Nyaga, Gilbert N., Judith M. Whipple , and Daniel F. Lynch (2010), “Examining Supply Chain Relationships: Do Buyer and Supplier Perspectives on Collaborative Relationships Differ?” Journal of Operations Management. 28:2, 101-114. Finalist, JOM Jack Meredith Best Paper of the Year Award based on 5-year impact. Whipple, Judith M., Daniel F. Lynch, and Gilbert N. Nyaga (2010), “A Buyer’s Perspective on Collaborative Versus Transactional Relationships.” Industrial Marketing Management. 39:3, 507-518 . 2009 Voss, M. Douglas, Judith M. Whipple , and David J. Closs (2009), “The Role of Strategic Security: Internal and External Security Measures with Security Performance Implications.” Transportation Journal. 48:2, 5-23 . Whipple, Judith M., M. Douglas Voss, and David J. Closs (2009), “Supply Chain Security Practices in the Food Industry: Do Firms Operating Domestically and Globally Differ?” International Journal of Physical Distribution and Logistics Management. 39:7, 574-594. Huddleston, Patricia, Judith M. Whipple , Rachel Nye Mattick, and So Jung Lee (2009), “Customer Satisfaction in Food Retailing: Comparing Specialty and Conventional Grocery Stores.” International Journal of Retail and Distribution Management. 37:1, 63-80. 2007 Jones, Kraig, Kellie Curry Raper, Judith M. Whipple , Diane Mollenkopf, and H. Christopher Peterson (2007), “Commodity-Procurement Strategies of Food Companies: A Case Study.” Journal of Food Distribution Research. XXXVIII:3, 37-53 . Whipple, Judith M. and Dawn Russell (2007) “Building Supply Chain Collaboration: A Typology of Collaborative Relationship Strategies.” The International Journal of Logistics Management. 18:2, 174-196. 2004 Sabath, Robert and Judith M. Whipple (2004), “Using the Customer/Product Action Matrix.” Journal of Business Logistics. 25:2, 1-19. Bernard J. La Londe Best Paper Award in the Journal – 2005. Huddleston, Patricia, Judith Whipple , and Amy VanAuken (2004), “Food Store Loyalty: Application of a Consumer Loyalty Framework.” Journal of Targeting, Measurement and Analysis for Marketing. 12:3, 213-230. 2002 Whipple, Judith M ., Robert Frankel, and Patricia J. Daugherty (2002), “Information Support for Alliances: Performance Implications.” Journal of Business Logistics. 23:2, 67-82. Frankel, Robert, Thomas J. Goldsby, and Judith M. Whipple (2002), “Grocery Industry Collaboration in the Wake of ECR.” International Journal of Logistics Management. 13:1, 57-72. Accenture Award for Best Paper in the Journal – 2002. Anselmi, Kenneth, Robert Frankel, and Judith Schmitz Whipple (2002), “Performance in Product Versus Service Supplier Relationships.” Journal of Business-to-Business Marketing. 9:1, 27-43. 2000 Whipple, Judith M. and Robert Frankel (2000), “Strategic Alliance Success Factors: Do Both Parties Agree?” The Journal of Supply Chain Management. 36:3 (Summer), 21-28 . Whipple, Judith Schmitz and Julie J. Gentry (2000), “A Network Comparison of Alliance Motives and Achievements.” Journal of Business and Industrial Marketing. 15:4/5, 301-322.

Supply Chain @ Broad

Get connected with broad:.

- Business College Complex

- 632 Bogue St

- East Lansing, MI 48824

- Browse All Articles

- Newsletter Sign-Up

SupplyChainManagement →

No results found in working knowledge.

- Were any results found in one of the other content buckets on the left?

- Try removing some search filters.

- Use different search filters.

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

A Simpler Way to Modernize Your Supply Chain

- David Simchi-Levi

- Kris Timmermans

Conventional wisdom says it takes three to five years and tens of millions of dollars to digitize a corporation’s supply chain. However, a few companies have reaped major benefits—including higher revenue and customer retention—with a faster, cheaper approach. It involves assembling available data; using analytics to understand and predict customers’ and suppliers’ behavior and optimize inventory, production, and procurement; and adding automation to revamp or introduce processes. The transformation requires three main initiatives: replacing consensus forecasts with one unified view of demand, changing one-size-fits-all supply strategies to segmented ones, and creating a plan to continually balance supply and demand and manage deviations or disruptions.

How to spend less and accomplish more

Idea in Brief

The conventional wisdom.

Digitizing a company’s system for managing its supply chain is a megatransformation project that takes three to five years and costs tens of millions of dollars.

The Reality

There is an alternative: Substantial benefits can be reaped from a modernization effort that takes 12 to 24 months and costs a few million dollars.

What It Entails

Assembling readily available data; using advanced analytics to understand and predict customers’ and suppliers’ behavior and to optimize inventory, production, and procurement decision-making; and adding some automation to revamp existing processes and introduce new ones.

Most executives believe that digitizing a major corporation’s supply chain costs tens of millions of dollars. The assumption is that it will be a massive three- to five-year transformation effort—requiring major investments in cloud technology, the installation of RFID tags and readers on every product container and in every facility, the deployment of 3D-printing and robotics technologies, and new instruments on machines on the shop floor to monitor their performance and condition. All that is necessary, the thinking goes, to break down the walls between functional areas and create an integrated supply chain that provides a competitive advantage.

- David Simchi-Levi is a professor of engineering systems at Massachusetts Institute of Technology and the head of the MIT Data Science Lab.

- Kris Timmermans is a senior managing director at Accenture and the head of its supply chain and operations practice. Connect with him on LinkedIn .

Partner Center

- Data, AI, & Machine Learning

- Managing Technology

- Social Responsibility

- Workplace, Teams, & Culture

- AI & Machine Learning

- Diversity & Inclusion

- Big ideas Research Projects

- Artificial Intelligence and Business Strategy

- Responsible AI

- Future of the Workforce

- Future of Leadership

- All Research Projects

- AI in Action

- Most Popular

- The Truth Behind the Nursing Crisis

- Work/23: The Big Shift

- Coaching for the Future-Forward Leader

- Measuring Culture

The spring 2024 issue’s special report looks at how to take advantage of market opportunities in the digital space, and provides advice on building culture and friendships at work; maximizing the benefits of LLMs, corporate venture capital initiatives, and innovation contests; and scaling automation and digital health platform.

- Past Issues

- Upcoming Events

- Video Archive

- Me, Myself, and AI

- Three Big Points

Supply Chains & Logistics

A tale of two hot sauces: spicing up diversification.

The dueling fortunes of two hot sauce companies demonstrate the power of strategic diversification.

Achal Bassamboo and James G. Conley

Global strategy, reality check: deglobalization.

There’s a widespread belief that U.S. companies are increasingly choosing to deglobalize. But is that really happening?

Omri Nahmias

Pair people and ai for better product demand forecasting.

A new framework can help companies fine-tune their product demand forecasting by using human and AI agents in concert.

Devadrita Nair and Maria Jesus Saenz

Content sponsored by amazon business, reinventing procurement: from cost center to innovation driver.

Todd Heimes of Amazon Business shares insights on procurement and digital transformation.

MIT SMR Connections

The looming challenge of chemical disclosures.

To comply with new sustainability rules, consumer brands need much more visibility into products’ chemical compositions.

Lori Bestervelt, Colleen McLoughlin, and Jillian Stacy

A reshoring renaissance is underway.

Geopolitics and supply chain resiliency are just two of the factors spurring some manufacturers to move back to the U.S.

Erin McLaughlin and Dana M. Peterson

Content sponsored by ey, staying compliant in a complex world: what today’s business leaders need to know.

This Strategy Guide offers expert insights and best practices for state-of-the-art compliance.

Analytics & Business Intelligence

Strategic alignment with ai and smart kpis.

When organizations create forward-looking smart KPIs with AI, they see increased strategic alignment.

David Kiron, Michael Schrage, François Candelon, Shervin Khodabandeh, and Michael Chu

Leading change, procurement in the age of automation.

Research points to six practices leaders can use to overcome stakeholder resistance to automated negotiation technology.

Remko Van Hoek and Mary Lacity

Taming the counterfeiting epidemic.

Businesses must take a multilayered approach to effectively combat counterfeit and unauthorized sales of their products.

Robert Handfield, Anand Nair, and Thomas Y. Choi

Are you ready for the next supply disruption.

Supply chain risks have become nearly incalculable. Managing them requires a capabilities-driven mindset.

M. Johnny Rungtusanatham, David A. Johnston, and Elizabeth Heichler

Financial management & risk, risk intelligence and the resilient company.

A more logical approach to risk management can help leaders sustain value generation through disruption and uncertainty.

Ananya Sheth and Joseph V. Sinfield

How e-commerce companies can reduce returns.

Research shows that product returns decrease when online shoppers receive orders in a single, consolidated delivery.

Pedro Amorim, Eduard Calvo, and Laura Wagner

Business models, new threats to the subscription model.

Inflation and supply chain disruption are exposing the risks of relying on a subscription model in some markets.

Oded Koenigsberg

Commodities markets are broken. responsible supply chains can fix them..

Transparency about how minerals are sourced advances environmental justice and climate protection.

Stephen Lezak, Valentina Guido, and Paolo Natali

Talent management, our guide to the winter 2023 issue.

This issue of MIT SMR focuses on creating and managing successful, engaged teams in a pandemic-changed world.

MIT Sloan Management Review

Get ready for the next supply disruption, m. johnny rungtusanatham and david a. johnston, supply chain leaders, prioritize these three talent strategy essentials.

To strengthen resiliency, companies need to build flexibility into the supply chain talent base.

Inge Oosterhuis and Kristine Renker

Big data in agriculture: land o’lakes’ teddy bekele.

Land O’Lakes’ CTO explains how data and artificial intelligence help the organization support agricultural production.

Sam Ransbotham and Shervin Khodabandeh

Unlocking the potential of digital twins in supply chains.

Digital twins can deliver immense benefits across a wide range of supply chains with the right implementation strategy.

Özden Tozanli and Maria Jesús Saénz

At the MIT Center for Transportation & Logistics

Thesis and Capstone Projects

A thesis or capstone project is a requirement for every graduate student at MIT.

The project needs to be practical, relevant, and address a problem of great interest to industry or other entities with supply chain challenges. These projects are performed with a sponsoring company, NGO, government agency, or trade association.

Students bid on projects in September, are matched with projects, partners, and SCM project advisors, and begin working with sponsoring companies shortly afterward. Residential cohort (SCMr) students visit sponsoring companies in October and have weekly calls with project sponsors throughout the academic year.

- Since projects usually require 9 months to complete, SCMb students must do some work at home before arriving on campus – see detailed timeline info below.

In December, students prepare a one-slide “e-poster” outlining their project, and present their work-in-progress at the MIT SCALE Supply Chain Expo at the end of January.

In May, students submit completed projects and present their work to the CTL community and project sponsors. Students may be asked to travel to sponsoring companies in June to present their project and findings to management.

Examples of past SCM projects can be found on the CTL site .

Project Process for Blended Pathway Students

Because SCMb students are on campus for only 5 months they must begin working on their projects in advance. Here is the sequence of work tasks:

Before Applying

- Project Topic: SCMb candidates should think about what kind of supply chain problem they want to work on. They will need to create a convincing two page description of their proposed project. They should think about what kind of an entity might wish to partner with them and what kind of data they will need to perform this project.

The Application (November to May)

- All students will complete a capstone project as a component of the program. Projects may be offered by the academic program or proposed directly by applicants. Projects proposed by applicants needs to be practical, relevant, data driven, and address a problem of great interest to industry or other entities with supply chain challenges. These projects are performed with a sponsoring company, NGO, government agency, or trade association.

- Applicants must submit a two page (1000 words) project proposal. Although preferred, this proposal does not require any commitment or discussion on the part of your sponsor. If admitted to the program you will have the option to expand on your proposal to be considered toward the completion of your degree.

- You must impress upon the review committee with the importance of your project to supply chain management and convince them that you can complete the project in a timely manner. Projects will require up to 4 months of remote pre-work prior to enrollment, plus additional time once enrolled in the on campus program.

- Describe the problem including what challenges, industries, markets, products, geographies, processes, etc. are involved?

- What organization or kind of organization will you seek to partner with you on this project?

- How do you propose to gain the cooperation of this kind of organization?

- What methodology would you use to study this problem?

- What types of data will you need to perform this project?

- How do you propose to obtain the data you need for this project?

- If accepted, what pre-work can you do before coming to campus?

- Can you complete this project in a 9-month time frame, both remote and on campus?

Once Admitted but Before Arrival on campus (August to December)

- Expanded Project Proposal – provide a more detailed description including research question, project scope, methodology, data required, and timing.

- Sources of Data – describe where the data will come from for your quantitative analysis. Show proof that such data exists and that you can get access to it.

- Letter from Sponsor (if collaborating with an entity) – provide a note from any sponsoring entity demonstrating that they intend to provide data and work with you on this project.

- Complete the edX Introduction to Computer Science and Programming Using Python course.

Arrival at MIT (first week of January)

- SCMb students arrive a week ahead of the rest of the SCM and SCALE students for orientation

- Students work on their project, attend career development workshops, writing classes, and leadership seminars.

SCALE Connect Expo (January) and Spring Semester – February to May

- SCMb students follow the same project schedule and due dates as the SCMr students

MIT SCM Symposium (May)

- SCMr and SCMb students present the final results of their projects in a day-long event.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

PROJECT ON SUPPLY CHAIN MANAGEMENT

Related Papers

Mohammad bilal Kazi

International Journal of Recent Research Aspects ISSN 2349-7688

In ongoing scenario, production and administration of a product or services and focus on core activities have lead to a perception that companies or firms are connected together in a network of supply chain. This created a challenge to coordinate the entire supply chain management in a fruitful manner. SCM has its roots since the business originated to provide product and services to the customers. SCM keeps on eye on the flow of information of goods and services in order to service maximum value to the customer. No research have been done till now which focuses on core initiative and constructs of SCM. The purpose of this study is to provide a criteria that flourishes knowledge of supply chain management and provide clear view to the researchers to understand the importance of theoretical investigation in different fields of supply chain management and explore the importance of its performance.. Keyword: Strategic purchasing in supply chain management; supply management; logistics integration; supply network coordination

roma manglani

Supply chain management (SCM) is the active management of supply chain activities to maximize customer value and achieve a sustainable competitive advantage. Supply chain management is the management of the flow of goods and services and includes all processes that transform raw materials into final products. It involves the active streamlining of a business's supply-side activities to maximize customer value and gain a competitive advantage in the marketplace. SCM represents an effort by suppliers to develop and implement supply chains that are as efficient and economical as possible. Supply chains cover everything from production to product development to the information systems needed to direct these undertakings. Typically, SCM attempts to centrally control or link the production, shipment, and distribution of a product. By managing the supply chain, companies are able to cut excess costs and deliver products to the consumer faster. This is done by keeping tighter control of internal inventories, internal production, distribution, sales, and the inventories of company vendors. SCM is based on the idea that nearly every product that comes to market results from the efforts of various organizations that make up a supply chain. Although supply chains have existed for ages, most companies have only recently paid attention to them as a value-add to their operations. A supply chain is the connected network of individuals, organizations, resources, activities, and technologies involved in the manufacture and sale of a product or service. A supply chain starts with the delivery of raw materials from a supplier to a manufacturer and ends with the delivery of the finished product or service to the end consumer. SCM oversees each touch point of a company's product or service, from initial creation to the final sale. With so many places along the supply chain that can add value through efficiencies or lose value through increased expenses, proper SCM can increase revenues, decrease costs, and impact a company's bottom line.

Kaveen Anushka

of Supply Chain Management, " layed out a clear and compelling case for excellence in supply chain management. The insights provided here remain remarkably fresh ten years later. M anagers increasingly fi nd themselves assigned the role of the rope in a very real tug of war—pulled one way by customers' mounting demands and the opposite way by the company's need for growth and profi tability. Many have discovered that they can keep the rope from snapping and, in fact, achieve profi table growth by treating supply chain management as a strategic variable. These savvy managers recognize two important things. First, they think about the supply chain as a whole—all the links involved in managing the fl ow of products, services, and information from their suppliers' suppliers to their customers' customers (that is, channel customers, such as distributors and retailers). Second, they pursue tangible outcomes—focused on revenue growth, asset utilization, and cost. Rejecting the traditional view of a company and its component parts as distinct functional entities, these managers realize that the real measure of success is how well activities coordinate across the supply chain to create value for customers, while increasing the profi tability of every link in the chain. Our analysis of initiatives to improve supply chain management by more than 100 manufacturers, distributors, and retailers shows many making great progress, while others fail dismally. The successful initiatives that have contributed to profi table growth share several themes. They are typically broad efforts, combining both strategic and tactical change. They also refl ect a holistic approach, viewing the supply chain from end to end and orchestrating efforts so that the whole improvement achieved—in revenue, costs, and asset utilization—is greater than the sum of its parts. 0 0 0 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 0 0 1 0 0 1 0 1 0 0 1 0 0 1 0 1 0 1 0 1 0 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 0 1 0 1 0 1 0 0 0 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 0 1 0 1 0 1 0 1 0 0 1 0 0 0 1 0 0

Supply Chain Management

Marcus Ambe

Oresanya K A B I R U Opemipo

Measuring Business Excellence

Adriana Backx Noronha Viana

IAEME PUBLICATION

IAEME Publication

A supply chain is the connected network of individuals, organizations, resources, activities, and technologies involved in the manufacture and sale of a product or service. A supply chain starts with the delivery of raw materials from a supplier to a manufacturer and ends with the delivery of the finished product or service to the end consumer. SCM oversees each touch point of a company's product or service, from initial creation to the final sale. With so many places along the supply chain that can add value through efficiencies or lose value through increased expenses, proper SCM can increase revenues, decrease costs, and impact a company's bottom line.

International Journal of Supply Chain Management

Hafsa Maryam

JENNIPHER ATIM

RELATED PAPERS

Clinical Nutrition Supplements

Miguel León Sanz

Journal of Advances in Applied & Computational Mathematics

Avanti Publisher

International Journal of Oral and Maxillofacial Surgery

Jose Crestanello

Economic Development and Cultural Change

Wiwik Anggraini

fera febriyani

Journal of Institute of Medicine Nepal

gopal sedain

International Journal of Fisheries and Aquatic Studies

Dr. Deepika Bhargava

Mandau Kristianto

Revista Lasallista de Investigación

CESAR AUGUSTO GAVIRIA CUARTAS

Revista Brasileira de Zootecnia

Wilson Dutra

Geographic Information Systems and Crime Analysis

Kevin Curtin

won-cheol yun

Elisiane Rocha

Pest Management Science

Wojciech Korcz

Atmospheric Environment

Alena Bartoňová

Syarif Hidayatullah

PLANNING MALAYSIA JOURNAL

Faris Faris

Acta Physica Polonica A

Lubica Stuchlikova

EMBO reports

Elisabetta Ristori

Eric Barnett

Cuadernos de Historia del Arte - Universidad Nacional de Cuyo

Laura Malosetti Costa

Journal of Computing Sciences in Colleges

T. Gagos and R. S. Bagnall (eds.), Essays and Texts in Honor of J. David Thomas

Peter van Minnen

Corina Gonzalez Weil

Applied Sciences

zimi sawacha

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

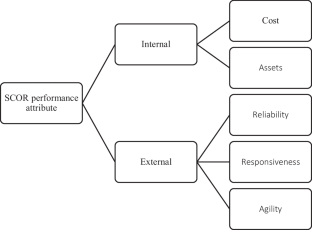

Measuring Supply Chain Performance Using the SCOR Model

- Published: 15 April 2024

- Volume 5 , article number 37 , ( 2024 )

Cite this article

- Thi Thuy Hanh Nguyen 1

23 Accesses

Explore all metrics

Performance measurement is critical for assessing the success of the supply chain. The supply chain operations reference (SCOR) model is one famous model used to measure supply chain performance. This study aims to identify gaps and provide future research directions using the SCOR for supply chain performance. Furthermore, this study proposed a conceptual framework that can be used as a guideline for real-life projects. This study was carried out in 2023 by reviewing previous articles that employed the SCOR model in supply chain performance between 2010 and 2022. The study applied the systematic mapping study processes to provide an overview of measuring supply chain performance using the SCOR model. This review disclosed that SCOR was a valuable management tool for measuring the performance of supply chains. It was one of the most commonly used models for assessing supply chain performance. The SCOR model has been used widely in different countries, industries, firms, and supply chains. Most of the previous studies worked with a case study and survey research. Level 1 of the SCOR metrics was employed the most. This review is the first attempt to investigate how the SCOR is used in supply chain performance measurement to the best of the author’s knowledge. Integrating emerging information technologies (such as blockchain, Internet of Things, artificial intelligence, and cloud computing) into the SCOR framework is a growing trend that drives the supply chain toward sustainability.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Supply Chain Performance Measurement: Current Challenges and Opportunities

A Current Review of Supply Chain Performance Measurement Systems

Performance Measurement – Value Creation

Data availability.

The data that support the findings of this study are publicly available.

Alomar M, Pasek ZJ (2014) Linking supply chain strategy and processes to performance improvement. Procedia CIRP 17:628–634. https://doi.org/10.1016/j.procir.2014.01.144

Article Google Scholar

Medini K, Rabénasolo B (2014) Analysis of the performance of supply chains configurations using multi-agent systems. Int J Log Res Appl 17(6):441–458. https://doi.org/10.1080/13675567.2014.894183

Reddy JMK, Neelakanteswara Rao A, Krishnanand L (2019b) A review on supply chain performance measurement systems. Procedia Manuf. https://doi.org/10.1016/j.promfg.2019.02.007

Kocaoǧlu B, Gülsün B, Tanyaş M (2013) A SCOR based approach for measuring a benchmarkable supply chain performance. J Intell Manuf 24(1):113–132. https://doi.org/10.1007/s10845-011-0547-z

Wibowo MA, Elizar SMN, Adji HS (2017) Supply chain management strategy for recycled materials to support sustainable construction. Procedia Eng 171:185–190. https://doi.org/10.1016/j.proeng.2017.01.325

Yadav S, Garg D, Luthra S (2021) Development of IoT based data-driven agriculture supply chain performance measurement framework. J Enterp Inf Manag 34(1):292–327. https://doi.org/10.1108/JEIM-11-2019-0369

Teixeira KC, Borsato M (2019) Development of a model for the dynamic formation of supplier networks. J Ind Inf Integr 15:161–173. https://doi.org/10.1016/j.jii.2018.11.007

Moharamkhani A, Bozorgi-Amiri A, Mina H (2017) Supply chain performance measurement using SCOR model based on interval-valued fuzzy TOPSIS. International Journal of Logistics Systems and Management 27(1):115–132. https://doi.org/10.1504/IJLSM.2017.083225

Ramaa A, Rangaswamy TM, Subramanya KN (2009) A review of literature on performance measurement of supply chain network. 2009 2nd International Conference on Emerging Trends in Engineering and Technology, ICETET 2009 802–807. https://doi.org/10.1109/ICETET.2009.18

Chorfi Z, Benabbou L, Berrado A (2018) An integrated performance measurement framework for enhancing public health care supply chains. Supply Chain Forum 19(3):191–203. https://doi.org/10.1080/16258312.2018.1465796

Bai C, Sarkis J (2012) Supply-chain performance-measurement system management using neighbourhood rough sets. Int J Prod Res 50(9):2484–2500. https://doi.org/10.1080/00207543.2011.581010

Estampe D, Lamouri S, Paris JL, Brahim-Djelloul S (2013) A framework for analysing supply chain performance evaluation models. Int J Prod Econ 142(2):247–258. https://doi.org/10.1016/j.ijpe.2010.11.024

Javed SA, Gunasekaran A, Mahmoudi A (2022) DGRA: Multi-sourcing and supplier classification through dynamic grey relational analysis method. Comp Indus Eng 173:108674. https://doi.org/10.1016/j.promfg.2019.02.007

Simão LE, Somensi K, Dávalos RV, Rodriguez CMT (2022) Measuring supply chain performance: the triple E model. Int J Product Perform Manag 71(7):2951–2969. https://doi.org/10.1108/IJPPM-06-2020-0291

Girjatovics A, Shekar SS, Kuznecova O, Pecerska J (2019) Simulation and SCOR: performance metrics integration to supply chain performance measurement. 2019 60th International Scientific Conference on Information Technology and Management Science of Riga Technical University (ITMS) 1–6. https://doi.org/10.1109/ITMS47855.2019.8940657

Bai C, Sarkis J, Wei X, Koh L (2012) Evaluating ecological sustainable performance measures for supply chain management. Supply Chain Manag 17(1):78–92. https://doi.org/10.1108/13598541211212221

Vlachos IP (2014) A hierarchical model of the impact of RFID practices on retail supply chain performance. Expert Syst Appl 41(1):5–15. https://doi.org/10.1016/j.eswa.2013.07.006

Piotrowicz W, Cuthbertson R (2015) Performance measurement and metrics in supply chains: an exploratory study. Int J Product Perform Manag 64(8):1068–1091

American Production and Inventory Control Society (2017) Supply chain operations reference model. In American Production and Inventory Control Society.

Delipinar GE, Kocaoglu B (2016) Using SCOR model to gain competitive advantage: a literature review. Procedia Soc Behav Sci 229:398–406. https://doi.org/10.1016/j.sbspro.2016.07.150

Srhir S, Jaegler A, Montoya-Torres JR (2023) Uncovering Industry 4.0 technology attributes in sustainable supply chain 4.0: a systematic literature review. Bus Strategy Environ 32(7):4143–4166. https://doi.org/10.1002/bse.3358

Lambert DM, Croxton KL (2005) An evaluation of process-oriented supply chain management frameworks 26(1):25–51

Google Scholar

Cheng JCP, Law KH, Bjornsson H, Jones A, Sriram RD (2010) Modeling and monitoring of construction supply chains. Adv Eng Inform 24(4):435–455. https://doi.org/10.1016/j.aei.2010.06.009

Supply Chain Council (2012) Supply chain operations reference model. In Supply Chain Operations Management. https://doi.org/10.1108/09576059710815716

Reddy JMK, Neelakanteswara Rao A, Krishnanand L (2019) A review on supply chain performance measurement systems. Procedia Manuf 30:40–47. https://doi.org/10.1016/j.promfg.2019.02.007

Huan SH, Sheoran SK, Wan G (2004) A review and analysis of supply chain operations reference (SCOR) model. Supply Chain Manag 9(1):23–29. https://doi.org/10.1108/13598540410517557

Ntabe EN, LeBel L, Munson AD, Santa-Eulalia LA (2015) A systematic literature review of the supply chain operations reference (SCOR) model application with special attention to environmental issues. Int J Prod Econ 169:310–332. https://doi.org/10.1016/j.ijpe.2015.08.008

Petersen K, Vakkalanka S, Kuzniarz L (2015) Guidelines for conducting systematic mapping studies in software engineering: An update. Inf Softw Technol 64:1–18. https://doi.org/10.1016/j.infsof.2015.03.007

Nishikawa-Pacher A (2022) Who are the 100 largest scientific publishers by journal count? A webscraping approach Journal of Documentation 78(7):450–463. https://doi.org/10.1108/JD-04-2022-0083

Gayialis SP, Kechagias EP, Papadopoulos GA, Masouras D (2022) A review and classification framework of traceability approaches for identifying product supply chain counterfeiting. Sustainability (Switzerland). https://doi.org/10.3390/su14116666

Naz F, Agrawal R, Kumar A, Gunasekaran A, Majumdar A, Luthra S (2022) Reviewing the applications of artificial intelligence in sustainable supply chains: exploring research propositions for future directions. Bus Strateg Environ 31(5):2400–2423. https://doi.org/10.1002/bse.3034

Lima-Junior FR, Carpinetti LCR (2017) Quantitative models for supply chain performance evaluation: A literature review. Comput Ind Eng 113:333–346. https://doi.org/10.1016/j.cie.2017.09.022

Ayyildiz E, Taskin Gumus A (2021) Interval-valued Pythagorean fuzzy AHP method-based supply chain performance evaluation by a new extension of SCOR model: SCOR 4.0. Complex Intell Syst 7(1):559–576. https://doi.org/10.1007/s40747-020-00221-9

Ganga GMD, Carpinetti LCR (2011) A fuzzy logic approach to supply chain performance management. Int J Prod Econ 134(1):177–187. https://doi.org/10.1016/j.ijpe.2011.06.011

Li L, Su Q, Chen X (2011) Ensuring supply chain quality performance through applying the SCOR model. Int J Prod Res 49(1):33–57. https://doi.org/10.1080/00207543.2010.508934

Elgazzar SH, Tipi NS, Hubbard NJ, Leach DZ (2012) Linking supply chain processes’ performance to a company’s financial strategic objectives. Eur J Oper Res 223(1):276–289. https://doi.org/10.1016/j.ejor.2012.05.043

Lee KH, Ru T, Shiu YS, Sivakumar P (2012) The applications of SCOR in manufacturing: two cases in Taiwan. Procedia Engineering 38:2548–2563. https://doi.org/10.1016/j.proeng.2012.06.300

Cirtita H, Glaser-Segura DA (2012) Measuring downstream supply chain performance. J Manuf Technol Manag 23(3):299–314. https://doi.org/10.1108/17410381211217380

Sheppard A, Tatham P, Fisher R, Gapp R (2013) A SCOR framework to measure logistics performance of humanitarian organizations. J Humanit Logisti Supply Chain Manag 3(1):22–36. https://doi.org/10.1108/JHLSCM-11-2013-0041

Zhang W, Reimann M (2014) Towards a multi-objective performance assessment and optimization model of a two-echelon supply chain using SCOR metrics. Cent Eur J Oper Res 22(4):591–622. https://doi.org/10.1007/s10100-013-0294-7

Jothimani D, Sarmah SP (2014) Supply chain performance measurement for third party logistics. Benchmarking 21(6):944–963. https://doi.org/10.1108/BIJ-09-2012-0064