Manufacturing Business Plan PDF Example

- May 7, 2024

- Business Plan

Creating a comprehensive business plan is crucial for launching and running a successful manufacturing business. This plan serves as your roadmap, detailing your vision, operational strategies, and financial plan. It helps establish your manufacturing business’s identity, navigate the competitive market, and secure funding for growth.

This article not only breaks down the critical components of a manufacturing business plan, but also provides an example of a business plan to help you craft your own.

Whether you’re an experienced entrepreneur or new to the manufacturing industry, this guide, complete with a business plan example, lays the groundwork for turning your manufacturing business concept into reality. Let’s dive in!

Our manufacturing business plan covers all essential aspects necessary for a comprehensive strategy. It details operations, marketing strategy , market environment, competitors, management team, and financial forecasts.

- Executive Summary : Provides an overview of the manufacturing company’s business concept, market analysis , management, and financial strategy.

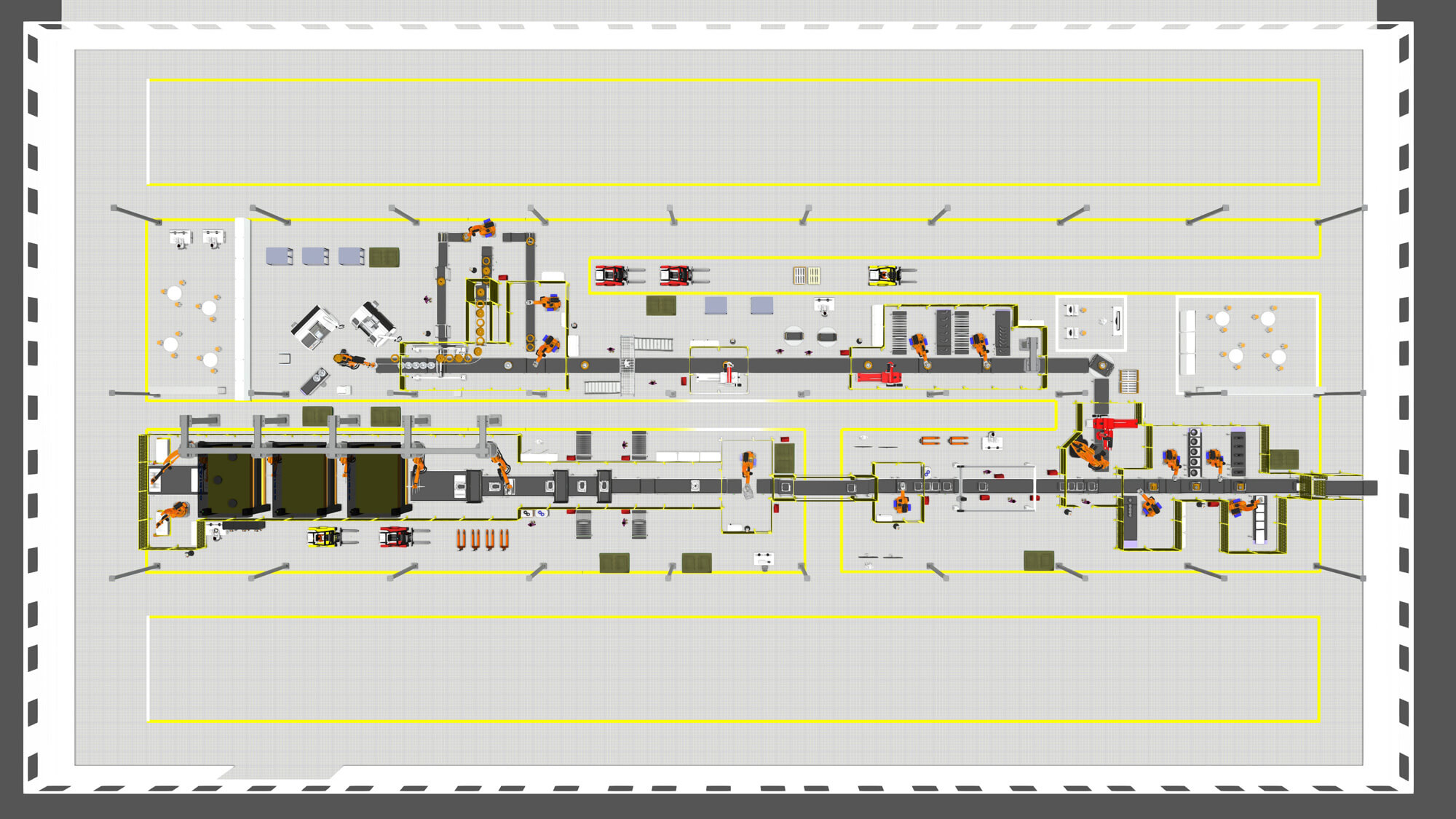

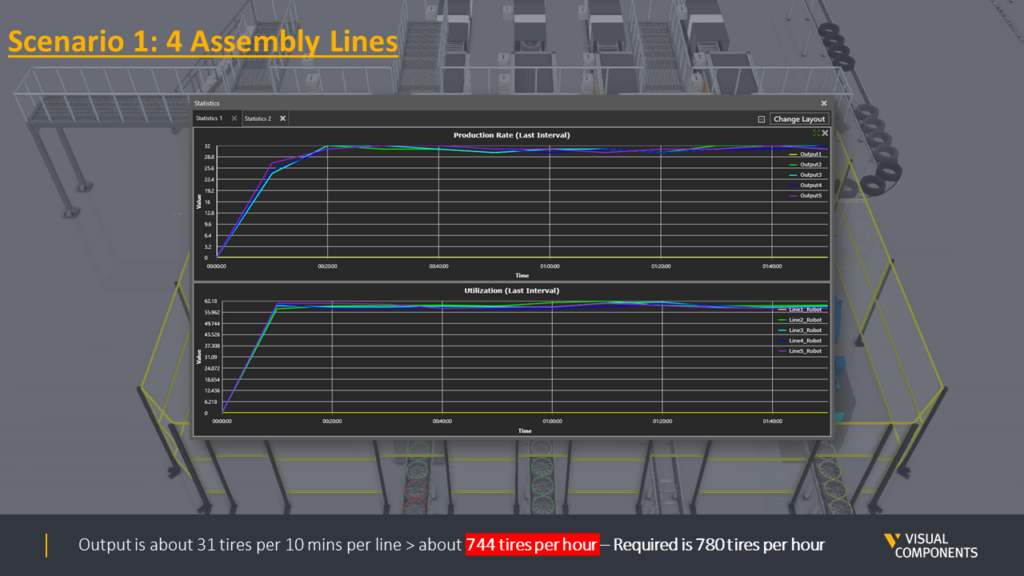

- Facilities & Equipment: Describes the facility’s capabilities, machinery, and technological advancements.

- Operations & Supply: Outlines the production processes, supply chain logistics, and inventory management.

- Key Stats: Offers data on industry size , growth trends, and market positioning.

- Key Trends: Highlights significant trends impacting the industry, such as automation and localization.

- Key Competitors : Analyzes primary competitors and differentiates the company from these rivals.

- SWOT: Analyzes strengths, weaknesses, opportunities, and threats.

- Marketing Plan : Outlines tactics for attracting new contracts and maintaining client relationships.

- Timeline : Sets out key milestones from inception through the first year of operations.

- Management: Information on the management team and their roles within the company.

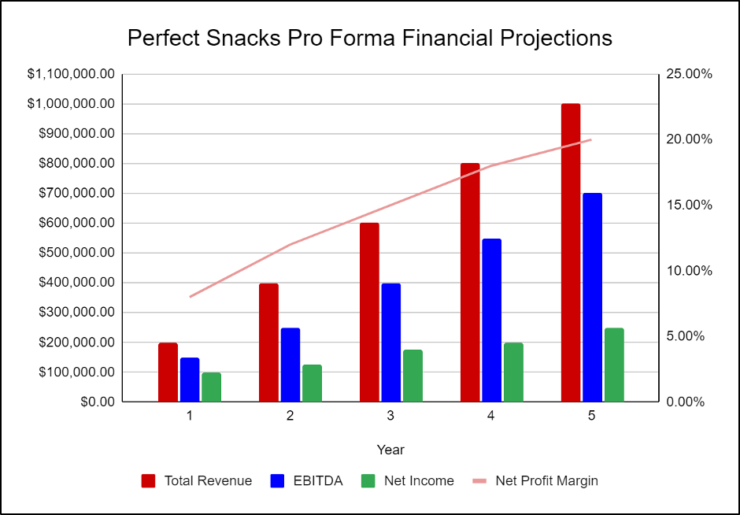

- Financial Plan: Projects the company’s financial performance over the next five years, detailing revenue, profits, and anticipated expenses.

Manufacturing Business Plan

Fully editable 30+ slides Powerpoint presentation business plan template.

Download an expert-built 30+ slides Powerpoint business plan template

Executive Summary

The Executive Summary introduces your manufacturing business plan, offering a concise overview of your manufacturing facility and its products. It should detail your market positioning, the range of products manufactured, the production process, its location, size, and an outline of day-to-day operations.

This section should also explore how your manufacturing business will integrate into the local and broader markets, including the number of direct competitors within the area, identifying who they are, along with your business’s unique selling points that differentiate it from these competitors.

Furthermore, you should include information about the management and co-founding team, detailing their roles and contributions to the business’s success. Additionally, a summary of your financial projections, including revenue and profits over the next five years, should be presented here to provide a clear picture of your business’s financial plan.

Make sure to cover here _ Business Overview _ Market Overview _ Management Team _ Financial Plan

Dive deeper into Executive Summary

Business Overview

Facilities & equipment.

Describe your manufacturing facility. Highlight its design, capacity, and technology. Mention the location, emphasizing accessibility to transport routes. Discuss advantages for efficiency and cost management. Detail essential equipment and its capabilities.

Operations & Supply Chain

Detail product range. Outline your operations strategy for efficiency and scalability. Discuss supply chain management. Highlight sourcing of materials, inventory control, and logistics. Emphasize strong partnerships with suppliers and distributors.

Make sure to cover here _ Facilities & Equipment _ Operations & Supplies

Market Overview

Industry size & growth.

Start by examining the size of the manufacturing industry relevant to your products and its growth potential. This analysis is crucial for understanding the market’s scope and identifying expansion opportunities.

Key Market Trends

Proceed to discuss recent market trends , such as the increasing demand for sustainable manufacturing processes, automation, and advanced materials. For example, highlight the demand for products that utilize eco-friendly materials or energy-efficient production techniques, alongside the rising popularity of smart manufacturing.

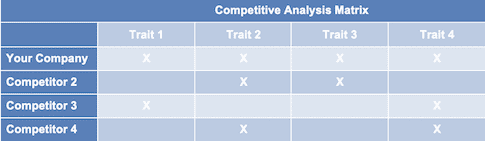

Key Competitors

Then, consider the competitive landscape, which includes a range of manufacturers from large-scale enterprises to niche firms. For example, emphasize what makes your business distinctive, whether it’s through advanced technology, superior product quality, or specialization in certain manufacturing niches. This section will help articulate the demand for your products, the competitive environment, and how your business is positioned to thrive within this dynamic market.

Make sure to cover here _ Industry size & growth _ Key competitors _ Key market trends

Dive deeper into Key competitors

First, conduct a SWOT analysis for your manufacturing business. Highlight Strengths such as advanced production technology and a skilled workforce. Address Weaknesses, including potential supply chain vulnerabilities or high production costs. Identify Opportunities like emerging markets for your products or potential for innovation in production processes. Consider Threats such as global competition or economic downturns that may impact demand for your products.

Marketing Plan

Next, develop a marketing strategy that outlines how to attract and retain customers through targeted advertising, trade shows, digital marketing, and strategic partnerships. Emphasize the importance of showcasing product quality and technological advantages to differentiate your business in the market.

Finally, create a detailed timeline that outlines critical milestones for your manufacturing business’s launch, marketing initiatives, customer acquisition, and expansion goals. Ensure the business progresses with clear direction and purpose, setting specific dates for achieving key operational and sales targets.

Make sure to cover here _ SWOT _ Marketing Plan _ Timeline

Dive deeper into SWOT

Dive deeper into Marketing Plan

The Management section focuses on the manufacturing business’s management and their direct roles in daily operations and strategic direction. This part is crucial for understanding who is responsible for making key decisions and driving the manufacturing business toward its financial and operational goals.

For your manufacturing business plan, list the core team members, their specific responsibilities, and how their expertise supports the business.

Financial Plan

The Financial Plan section is a comprehensive analysis of your financial projections for revenue, expenses, and profitability. It lays out your manufacturing business’s approach to securing funding, managing cash flow, and achieving breakeven.

This section typically includes detailed forecasts for the first 5 years of operation, highlighting expected revenue, operating costs and capital expenditures.

For your manufacturing business plan, provide a snapshot of your financial statement (profit and loss, balance sheet, cash flow statement), as well as your key assumptions (e.g. number of customers and prices, expenses, etc.).

Make sure to cover here _ Profit and Loss _ Cash Flow Statement _ Balance Sheet _ Use of Funds

Related Posts

Outdoor Sports Gear Store Business Plan PDF Example

- May 29, 2024

Shoe Store Business Plan PDF Example

Auto Parts Store Business Plan PDF Example

Privacy overview.

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

You’ve come to the right place to create your Manufacturing business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Manufacturing companies.

Below is a template to help you create each section of your Manufacturing business plan.

Executive Summary

Business overview.

Perfect Snacks, located in Lincoln, Nebraska, is a food manufacturing company that specializes in the production of snack foods and packaged goods. We manufacture an extensive line of snack products, including trail mix, gummies, and chocolate. Our company focuses on quality and only uses the best natural ingredients in our products. We will primarily sell our products to grocery stores and other establishments that sell snacks, but will also sell bulk orders to individual customers through our website.

Perfect Snacks was founded by Joe Boseley. Joe has been working on the manufacturing company concept over the past few years and began networking with grocery store clients and locating the land to build his manufacturing and distribution center. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Product Offering

Perfect Snacks will manufacture an extensive list of sweet, salty, and healthy snacks. Some of our initial products will include:

We will primarily sell our products to grocery stores, recreation centers, and other businesses that sell snacks in bulk. Consumers can find our products in stores or buy them in bulk on our website.

Customer Focus

Perfect Snacks will primarily serve the residents of Lincoln, Nebraska. The community has a large population of families and children, who are the primary consumers of snack foods. Therefore, we will market our products to recreational centers, schools, grocery stores, and other establishments that sell snacks to children and their parents.

Management Team

Perfect Snacks is owned by Joe Boseley, a local entrepreneur who has worked in various warehouses and manufacturing companies in Lincoln, Nebraska. Working in the manufacturing industry and in warehouses, Joe is very familiar with the processing and distribution of packaged foods. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Joe will utilize his past experience with developing staff roles and functions. He is also very familiar with the manufacturing equipment and plans to purchase the latest technology that is efficient and cost effective. His contacts have allowed him to gain concrete Letters of Intent from local supermarket chains to have his manufactured goods in their stores.

Success Factors

Perfect Snacks will be able to achieve success by offering the following competitive advantages:

- Taste: Perfect Snacks’ snack products will be made with the highest quality ingredients and offer quality over quantity.

- Price: Perfect Snacks is able to offer the highest quality snacks at a competitive price point.

- Community Relations: Perfect Snacks will be a pillar in the community and be heavily involved in family-related activities in the area. It will sponsor events, provide snacks for schools and daycares at a discounted price, and donate a portion of its proceeds to area family-related charities and organizations.

- Proprietary Technology: Perfect Snacks will invest heavily on the latest technology to manufacture the snack foods for distribution. It will ensure the food products are made safely and free from any harmful chemicals and ingredients.

Financial Highlights

Perfect Snacks is seeking a total funding of $1,200,000 of debt capital to open its manufacturing company. The capital will be used for funding capital expenditures, salaries, marketing expenses, and working capital. Specifically, these funds will be used as follows:

- Manufacturing facility design/build-out: $400,000

- Equipment and supplies: $375,000

- Initial inventory: $100,000

- Three months of overhead expenses (payroll, rent, utilities): $250,000

- Marketing costs: $50,000

- Working capital: $25,000

The following graph below outlines the pro forma financial projections for Perfect Snacks.

Company Overview

Who is perfect snacks, perfect snacks history.

After conducting a market analysis, Joe Boseley began surveying the local vacant warehouse space and decided on a parcel of land to construct the warehouse and distribution center. Joe incorporated Perfect Snacks as a Limited Liability Corporation on January 1st, 2023.

Once the land is acquired for the warehouse space, construction can begin to build-out the manufacturing facility.

Since incorporation, the Company has achieved the following milestones:

- Located a vacant lot that would be ideal for a manufacturing facility

- Developed the company’s name, logo, and website

- Hired a general contractor and architect for the build-out of the warehouse, small office, and distribution area

- Determined equipment and necessary supplies

- Determined beginning inventory

- Attained Letters of Intent from supermarket clients

- Began recruiting key employees

Perfect Snacks Services

Industry analysis.

The Manufacturing sector’s performance is largely attributable to the value of the US dollar, commodity prices, policy decisions and US manufacturing capacity. Food manufacturing has a history of success as it produces a basic human need. According to Grand View Research, the industry is currently valued at $121 billion and is expected to expand at a compound annual growth rate of 9.5% from now until 2030.

Commodity prices are currently stabilizing from coronavirus-induced volatility and renewed demand, both in the United States and global economies, which is anticipated to facilitate revenue expansion for manufacturers. Moreover, shifting technological change in the Manufacturing sector is anticipated to benefit large, developed economies, such as the United States. Therefore, now is a great time to start a new food manufacturing company in the U.S.

Customer Analysis

Demographic profile of target market.

Perfect Snacks will serve the community residents of Lincoln, Nebraska and its surrounding areas. The community of Lincoln, Nebraska has thousands of households that have children. Statistics show that the main consumers of snack products are children of all ages. They are regularly placed in school lunchboxes, afterschool snacks and programs, and at weekend sporting events. Therefore, we will market to locations where snacks are bought by children or their parents, such as grocery stores, recreational centers, and schools.

The precise demographics Lincoln, Nebraska is as follows:

Customer Segmentation

Perfect Snacks will primarily target the following customer profiles:

- Grocery stores and recreational centers

Competitive Analysis

Direct and indirect competitors.

Perfect Snacks will face competition from other companies with similar business profiles. A description of each competitor company is below.

Snacks N More

Snacks N More is another local manufacturing company that provides snack food to the immediate area. Established over thirty years ago, the company has the knowledge and expertise in food processing, commercialization, and packaging. They are known as a recognized ingredient supplier for the foodservice industry. Their portfolio of products include a variety of nuts, snacks, confections, and dry-blend ingredients. As a private label manufacturer, Snack’s More produces a full line of non-chocolate candy, nuts, and fruit-flavored snacks. The company is known for their fruit flavored snacks, dried raisins, nut mixes, and producing ingredients for local restaurants and establishments. Their line of nuts and dried fruits are often used for baking purposes.

Jaxon’s Candy

Jaxon’s Candy is a manufacturer of all things candy related. As a contract manufacturer, the company works with many companies to create their custom designed confections. Their large 50,000 square foot facility produces over 300,000 pounds of candy every month. All of the products are highly concentrated either in sugar or chocolate, or both. Jaxon’s Candy also designs and manufactures their own custom packaging. The candy produced is also kosher certified, gluten free, peanut free, and non-GMO.

Jaxon’s Candy currently manufactures candy for the following brands – Tommy Candy, Laffy Town, Chocowhoawhoa, Jellylicious, Healthee Candeee, and Sticky Teeth. Jaxon’s Candy can be found in grocery stores and convenient stores along the west coast of the United States.

Gimmy Candy

Gimmy Candy is located in the midwestern portion of the United States and boasts a facility of over 1 million square feet. Their fleet of transportation trucks distributes throughout the continental United States and is considered one of the largest candy manufacturers in the country. Their product portfolio includes assorted chocolates, gummy candy, hard candy, fruit candy, as well as gums and mints. Gimmy Candy was established in 1947 and has grown to be a model of manufacturing companies the industry uses as a model of sustainability and profitability. Their lineup of candy products can be found in every single grocery store and convenient store in the country. Gimmy Candy is considering expanding its distribution globally and start exporting its candy products to Asia, Canada, Europe, and South America. As one of the largest privately held companies in the United States, Gimmy Candy is also considered a top employer in the country and offers its employees a generous benefits package.

Competitive Advantage

Perfect Snacks will be able to offer the following advantages over their competition:

Marketing Plan

Brand & value proposition.

Perfect Snacks will offer the unique value proposition to its clientele:

- Fresh and comforting taste

- Community family advocate

- Developed with proprietary technology

- Manufactured with fresh, quality ingredients

- Affordable price

Promotions Strategy

The promotions strategy for Perfect Snacks is as follows:

Social Media

Perfect Snacks will invest heavily in a social media advertising campaign. The brand manager will create the company’s social media accounts and invest in ads on all social media accounts. It will use targeted marketing to appeal to the target demographics.

Website/SEO

Perfect Snacks will invest heavily in developing a professional website that displays all of the features and benefits of the snack products. It will also invest heavily in SEO so that the brand’s website will appear at the top of search engine results.

Major Publications

We will also invest in advertising in selected larger publications until we have achieved significant brand awareness. Advertisements such as billboards and commercials will be shown during peak tv watching time and the billboards will be placed in highly trafficked areas.

Sponsorships

Perfect Snacks will also invest in sponsoring certain athletic and school events so that their banners and collateral material are displayed all over the event where numerous parents and children are at.

Perfect Snacks’s pricing will be moderate so consumers feel they receive great value when purchasing our snack products.

Operations Plan

The following will be the operations plan for Perfect Snacks.

Operation Functions:

- Joe Boseley will be the CEO of Perfect Snacks. He will oversee the general operations and executive aspects of the business.

- Joe is joined by Candace Smith who will act as the warehouse manager. She will train and manage the staff as well as oversee general production of our products.

- Joe will hire an Administrative Assistant, Marketing Manager, and Accountant, to handle the administrative, marketing, and bookkeeping functions of the company.

- Joe will also hire several employees to manufacture our products and maintain the equipment and machinery.

Milestones:

Perfect Snacks will have the following milestones complete in the next six months.

- 02/202X Finalize lease agreement

- 03/202X Design and build out Perfect Snacks

- 04/202X Hire and train initial staff

- 05/202X Kickoff of promotional campaign

- 06/202X Launch Perfect Snacks

- 07/202X Reach break-even

Financial Plan

Key revenue & costs.

Perfect Snacks’s revenues will come primarily from its snack food sales. The company will sell the packaged snacks in local grocery stores, convenience stores, and other locations. As the company’s revenues increase, it will look to gain a wider distribution area.

The land purchase, equipment, supplies, opening inventory, and labor expenses will be the key cost drivers of Perfect Snacks. Other cost drivers include taxes, business insurance, and marketing expenditures.

Funding Requirements and Use of Funds

Key assumptions.

The following outlines the key assumptions required in order to achieve the revenue and cost numbers in the financials and pay off the startup business loan.

- Average order value: $250

Financial Projections

Income statement, balance sheet, cash flow statement, manufacturing business plan faqs, what is a manufacturing business plan.

A manufacturing business plan is a plan to start and/or grow your manufacturing business. Among other things, it outlines your business concept, identifies your target customers, presents your marketing plan and details your financial projections.

You can easily complete your Manufacturing business plan using our Manufacturing Business Plan Template here .

What are the Main Types of Manufacturing Businesses?

There are a number of different kinds of manufacturing businesses , some examples include: Garment manufacturing, Food product manufacturing, Diaper manufacturing, Tile manufacturing, and Toy manufacturing.

How Do You Get Funding for Your Manufacturing Business Plan?

Manufacturing businesses are often funded through small business loans. Personal savings, credit card financing and angel investors are also popular forms of funding.

What are the Steps To Start a Manufacturing Business?

Starting a manufacturing business can be an exciting endeavor. Having a clear roadmap of the steps to start a business will help you stay focused on your goals and get started faster.

1. Develop A Manufacturing Business Plan - The first step in starting a business is to create a detailed manufacturing business plan that outlines all aspects of the venture. This should include potential market size and target customers, the services or products you will offer, pricing strategies and a detailed financial forecast.

2. Choose Your Legal Structure - It's important to select an appropriate legal entity for your manufacturing business. This could be a limited liability company (LLC), corporation, partnership, or sole proprietorship. Each type has its own benefits and drawbacks so it’s important to do research and choose wisely so that your manufacturing business is in compliance with local laws.

3. Register Your Manufacturing Business - Once you have chosen a legal structure, the next step is to register your manufacturing business with the government or state where you’re operating from. This includes obtaining licenses and permits as required by federal, state, and local laws.

4. Identify Financing Options - It’s likely that you’ll need some capital to start your manufacturing business, so take some time to identify what financing options are available such as bank loans, investor funding, grants, or crowdfunding platforms.

5. Choose a Location - Whether you plan on operating out of a physical location or not, you should always have an idea of where you’ll be based should it become necessary in the future as well as what kind of space would be suitable for your operations.

6. Hire Employees - There are several ways to find qualified employees including job boards like LinkedIn or Indeed as well as hiring agencies if needed – depending on what type of employees you need it might also be more effective to reach out directly through networking events.

7. Acquire Necessary Manufacturing Equipment & Supplies - In order to start your manufacturing business, you'll need to purchase all of the necessary equipment and supplies to run a successful operation.

8. Market & Promote Your Business - Once you have all the necessary pieces in place, it’s time to start promoting and marketing your manufacturing business. This includes creating a website, utilizing social media platforms like Facebook or Twitter, and having an effective Search Engine Optimization (SEO) strategy. You should also consider traditional marketing techniques such as radio or print advertising.

Getting started: A guide to creating a manufacturing business plan

What is a manufacturing business plan.

A manufacturing business plan is a formal document that outlines the goals and objectives of your business. It includes detailed information about your:

- Products or services

- Target market

- Marketing strategy

- Financial projections

- Operational details

The purpose of a business plan is to give you a roadmap to follow as you build and grow your business. It forces you to think through every aspect of your venture and identify potential problems or roadblocks before they happen.

Manufacturing business plans can also be used to attract investors or secure funding from lenders. If you are looking for outside financing, your business plan needs to be even more detailed and include information on your management team, financial history, and expected growth.

Ideally, you should update your business plan yearly to ensure that it remains relevant and accurate. As your business grows and changes, so too should your plan.

Why does a manufacturing company need a business plan?

No matter how simple or complex your ideas may be, you need a plan, or they will never become a reality. A business plan will clearly understand your costs, competition, and target market. It will also help you to set realistic goals and track your progress over time.

Let’s look at a manufacturing strategy example. You have a great idea that you think will revolutionize the automotive industry . Your new safety harness will be made from a lightweight, yet incredibly strong, material that cannot be cut or torn. You are confident that your product will be in high demand and generate a lot of revenue.

But before you walk into Ford or Toyota to try and get a purchase order , you need to have a plan. You must know:

- How much will it cost to produce your product

- How many units do you need to sell to break even

- Who is your target market is

- What is your competition selling

- How will you reach your target market

You also need to clearly understand the regulatory landscape and what it takes to bring a new product to market. All of this information (and more) should be included in your business plan.

This is not just a document that you create and forget about. It is a living, breathing tool that should be used to guide your actions as you build and grow your business.

What are the key components of a business plan?

Every manufacturing business plan will be different, but almost always, they will include the same five components:

Executive summary

Company description, products and services, market analysis.

- Financial plan

Let’s take a closer look.

The executive summary is the first section of your business plan, but it is typically written last. This is because it should be a concise overview of everything that follows, and you can only do that once you have completed the rest of your plan.

Include the following in your executive summary:

- The problem that your product or service solves

- Your target market

- Your unique selling proposition (what makes you different from your competitors?)

- Your manufacturing business model (how will you make money?)

- Your sales and marketing strategy

- A brief overview of your financial projections

Someone should be able to quickly scan through your executive summary and have a pretty good understanding of what your business is and how it plans to be successful.

This is where you can get a bit more creative, explaining your company’s history, mission, and values. You will also include information on your team or management structure.

It can be simple but should inspire faith in your ability to execute your business plan.

You will need to provide a detailed description of your product or service, as well as any unique features or benefits that it offers. You should also include information on your manufacturing process and quality control procedures.

If you have any patents or proprietary technology, they should be listed here as significant assets for your business.

For example, let’s say you are planning on creating a brand-new line of disposable coffee cups. The dimensions, materials, and other specifications would be listed here, along with any unique benefits (such as being made from recycled materials).

You might also include information on your manufacturing process, such as the fact that the cups will be produced in a certified clean room or that you will employ workers local to where the product is sold.

Chances are, you started down this path because you realized that there was a market opportunity for your product or service. In this section, you will need to provide detailed information on the opening, as well as the analysis that convinced you to pursue it.

This should include:

- Market size (current and projected)

- Key market segments

- Customer needs and wants

- Competitive landscape

This is where you will need to do your homework, as you will be justifying your business decision to enter this particular market. The more data and analysis you can provide, the better.

For our coffee cup example, the market analysis might include:

- Information on how many cups are used every day

- Projected growth

- Key segments (such as office workers or on-the-go consumers)

- Customer needs (such as convenience or sustainability)

It would also examine the competitive landscape, including both direct and indirect competitors.

Financial plan

You’re in this to make money, and so are your potential investors. In this section, you will need to provide detailed information on your manufacturing business model and how it will generate revenue. This should include:

- Initial investment

- Sales forecast

- Carrying costs

- Pricing strategy

- Expense budget

You will also need to provide information on your long-term financial goals, such as profitability or break-even point. Discuss production line details, inventory management strategies , and other factors impacting your bottom line.

How to write a business plan for a manufacturing company

The process of creating a business plan for a manufacturing company is similar to any other type of business. However, there are some key considerations to keep in mind.

First, you need to understand your industry and what it will take to be successful in it. This includes understanding the competitive landscape, the costs of goods sold , and the margins you can expect to achieve.

You also need to have a clear understanding of your target market and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits.

While there will be many things specific to your company, here are five questions to answer for each of the sections listed above.

Executive summary:

- What is the problem that your company will solve?

- How will your company solve that problem?

- Who are your target customers?

- What are your key competitive advantages?

- What is your business model?

Company description:

- What is the legal structure of your company?

- What are your company’s core values?

- What is your company’s history?

- Who are the key members of your management team?

- Where is your manufacturing facility located?

Products and services:

- What product or service does your company offer?

- How does your product or service solve the problem that your target market has?

- What are the key features and benefits of your product or service?

- How is your product or service unique from your competitors?

- What is the production process for your product or service?

Market analysis:

- Who is your target market?

- What needs or wants does your target market have that your product or service will address?

- What is the size of your target market?

- How do you expect the needs of your target market to change in the future?

- Who are your key competitors, and how do they serve the needs of your target market?

Financial plan:

- What are the start-up costs for your company?

- How will you finance your start-up costs?

- What are your monthly operating expenses?

- What is your sales forecast for the first year, and how does that compare to your industry’s average sales growth rate?

- What are your gross margin and profit targets?

Even if you do nothing but answer these questions, you’ll be well on your way to creating a thorough manufacturing business plan.

How to stabilize your growth

When getting started, managing your business with spreadsheets might be okay. But, once sales and manufacturing orders start to increase, the inefficiencies of manually managing your business come to light. That’s why many turn to automation to keep their manufacturing on track.

Common mistakes to avoid

However, new manufacturing entrepreneurs often fall into a handful of traps when creating their business plans.

- Not doing enough research – You can’t know everything about your industry, but you should do your best to understand as much as you can before writing your business plan. This means talking to experts, reading trade publications, and studying the competition

- Not being realistic – It’s important to be optimistic when starting a new business, but you also need to be realistic. This is especially true when it comes to financial projections. Don’t overestimate the amount of revenue you will generate or underestimate the costs of goods sold

- Not having a clear understanding of your target market – You need to know who you are selling to and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits

- Failing to understand your competition – You need to know who your competitors are, what they are offering, and how you can differentiate yourself. This information will be critical in developing your marketing strategy

- Not having a clear vision for the future – Your manufacturing business plan should include a section on your long-term goals and objectives. What does your company hope to achieve in the next five years? Ten years? Twenty years?

Creating a business plan for manufacturing can be simple. It can be quite simple if you break it down into smaller pieces.

Once you have it in place, staying on track can be quite a bit more difficult. By using ERP software like Katana , you can track all of your key metrics in real time, avoid any potential issues, and make course corrections as needed.

To start following your plan and creating a successful manufacturing company, get a Katana demo today.

Table of contents

Manufacturing guide.

1. What is manufacturing

1. 1. Production vs. manufacturing

1.2. Production scheduling software

1.3. Production tracking software

2. How to start a manufacturing business

2.1.How to manufacture a product

2.2. Manufacturing best practice

2.3. A guide to creating a manufacturing business plan

2.4. Manufacturer ecommerce

2.5. Marketing for manufacturers

2.6. Manufacturing business processes

2.7. Food manufacturing

2.8. Small business manufacturing software

3. Manufacturing processes

3.1. Job shop manufacturing

3.2. Production quality control checklist

4. Lean manufacturing principles

4.1. Just-in-time (JIT) manufacturing

4.2. Tips to reduce manufacturing waste

4.3. Manufacturing KPIs

5. Light manufacturing

6. Advanced manufacturing

7. IoT in manufacturing

8. Manufacturing challenges

9. Total manufacturing cost

9.1. Manufacturing overhead formula

9.2. Manufacturing inventory software

10. Good manufacturing practices

11. MRP systems

11.1. MRP in supply chain management

11.2. Best MRP software

12. Manufacturing ERP systems

12.1. Best ERP software for manufacturing

12.2. Manufacturing execution systems (MES)

More guides from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

Over the past 20+ years, we have helped over 7,000 entrepreneurs and business owners create business plans to start and grow their manufacturing businesses. On this page, we will first give you some background information with regards to the importance of business planning. We will then go through a manufacturing business plan template step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What is a Manufacturing Business Plan?

A business plan provides a snapshot of your manufacturing business as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategy for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan for a Manufacturing Company

If you’re looking to start a new manufacturing business, or grow your existing manufacturing business, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your manufacturing business in order to improve your chances of success. Your business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Manufacturing Businesses

With regards to funding, the main sources of funding for a manufacturing business are personal savings, credit cards, bank loans and angel investors. With regards to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to confirm that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business.

Personal savings is the other most common form of funding for a manufacturing business. Venture capitalists will usually not fund a manufacturing business. They might consider funding a manufacturing business with a national presence, but never an individual location. This is because most venture capitalists are looking for millions of dollars in return when they make an investment, and an individual location could never achieve such results. With that said, personal savings and bank loans are the most common funding paths for manufacturing businesses.

Finish Your Business Plan Today!

How to write a business plan for a manufacturing company.

If you want to start a manufacturing business or expand your current one, you need a business plan. Below we detail what you should include in each section of your own business plan:

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of manufacturing business you are operating and the status. For example, are you a startup, do you have a manufacturing business that you would like to grow, or are you operating a chain of manufacturing businesses?

Next, provide an overview of each of the subsequent sections of your plan. For example, give a brief overview of the manufacturing industry. Discuss the type of manufacturing business you are operating. Detail your direct competitors. Give an overview of your target market. Provide a snapshot of your marketing strategy. Identify the key members of your team. And offer an overview of your financial plan.

Company Analysis

In your company analysis, you will detail the type of business you are operating.

There are many types of manufacturing businesses, such as:

- Clothing manufacturing

- Garment manufacturing

- Food product manufacturing

- Diaper manufacturing

- Tile manufacturing

- Toy manufacturing

- Soap and detergent manufacturing

- Mobile accessories manufacturing

- Mattress manufacturing

- Bicycle manufacturing

- Pillow manufacturing

- Brick manufacturing

- Toilet paper manufacturing

- Furniture manufacturing

- Peanut butter manufacturing

- Cosmetics manufacturing

- Footwear manufacturing

In addition to explaining the type of manufacturing business you will operate, the Company Analysis section of your business plan needs to provide background on the business.

Include answers to question such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of customers served, number of positive reviews, number of wholesale contracts, etc.

- Your legal structure. Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry or market analysis, you need to provide an overview of the manufacturing industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the manufacturing industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your strategy, particularly if your research identifies market trends.

The third reason for market research is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section:

- How big is the manufacturing industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential market for your manufacturing business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your local population.

Customer Analysis

The customer analysis section must detail the customers you serve and/or expect to serve.

The following are examples of target market segments: wholesalers, other manufacturers, exports, retailers.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of manufacturing business you operate. Clearly, retailers would respond to different marketing promotions than export markets, for example.

Try to break out your target market in terms of their demographic and psychographic profiles. With regards to demographics, include a discussion of the ages, genders, locations and income levels of the customers you seek to serve. Because most manufacturing businesses primarily serve customers living in their same city or town, such demographic information is easy to find on government websites.

Psychographic profiles explain the wants and needs of your target customers. The more you can understand and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Manufacturing Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other manufacturing businesses.

Indirect competitors are other options that customers have to purchase from that aren’t direct competitors. This includes manufacturers in other niches, as well as those vertically integrated businesses that make their own product. You need to mention such competition as well.

With regards to direct competition, you want to describe the other manufacturing businesses with which you compete. Most likely, your direct competitors will be house flippers located very close to your location.

For each such competitor, provide an overview of their businesses and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as:

- What types of customers do they serve?

- What types of products do they manufacture?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you provide high quality manufacturing practices?

- Will you provide services that your competitors don’t offer?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a manufacturing business, your marketing strategy should include the following:

Product : In the product section, you should reiterate the type of manufacturing company that you documented in your Company Analysis. Then, detail the specific products you will be offering. For example, in addition to manufacturing, will you provide R&D, design, prototyping or any other services?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your marketing plan, you are presenting the services you offer and their prices.

Place : Place refers to the location of your manufacturing company. Document your location and mention how the location will impact your success. For example, is your manufacturing business located near a distribution hub, etc. Discuss how your location might be the ideal location for your customers.

Promotions : The final part is the promotions section. Here you will document how you will drive customers to your location(s). The following are some promotional methods you might consider:

- Advertising in local papers and magazines

- Reaching out to local websites

- Social media marketing

- Local radio advertising

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your manufacturing business, including sourcing inputs, designing processes, managing production, coordinating logistics and meeting with potential buyers.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to secure your 1,000 th contract, or when you hope to reach $X in revenue. It could also be when you expect to expand your manufacturing business to a new city.

Management Team

To demonstrate your manufacturing business’ ability to succeed, a strong team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally you and/or your team members have direct experience in managing manufacturing businesses. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act like mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in manufacturing or successfully running small businesses.

Financial Plan

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet and cash flow statements.

Income Statement : an income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenues and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you offer short-run production, or will you focus strictly on long-run? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets : Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your manufacturing business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a bank writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement : Your cash flow statement will help determine how much money you need to start or grow your business, and make sure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

In developing your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a manufacturing business:

- Location build-out including design fees, construction, etc.

- Cost of equipment and supplies

- Payroll or salaries paid to staff

- Business insurance

- Taxes and permits

- Legal expenses

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your production facility blueprint, or capabilities specifications.

Putting together a business plan for your manufacturing business is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will really understand the manufacturing industry, your competition, and your customers. You will have developed a marketing plan and will really understand what it takes to launch and grow a successful manufacturing business.

Manufacturing Business Plan FAQs

What is the easiest way to complete my manufacturing business plan.

Growthink's Ultimate Business Plan Template allows you to quickly and easily complete your Manufacturing Business Plan.

What is the Goal of a Business Plan's Executive Summary?

The goal of your Executive Summary is to quickly engage the reader. Explain to them the type of manufacturing business you are operating and the status; for example, are you a startup, do you have a manufacturing business that you would like to grow, or are you operating a chain of manufacturing businesses?

Don’t you wish there was a faster, easier way to finish your Manufacturing business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. Click here to see how Growthink’s professional business plan consulting services can create your business plan for you.

Other Helpful Business Plan Articles & Templates

Manufacturing Business Plan Template & Guidebook

Starting a manufacturing business is an exciting endeavor, but it can be daunting to know where to start. Fortunately, the #1 Manufacturing Business Plan Template & Guidebook provides entrepreneurs and businesses with a detailed roadmap for success. With this template and guidebook, you will have the guidance you need to plan for success and develop a comprehensive business plan that outlines your vision and strategy.

Get worry-free services and support to launch your business starting at $0 plus state fees.

- How to Start a Profitable Manufacturing Business [11 Steps]

- 10+ Best & Profitable Manufacturing Business Ideas [2023]

- 25 Catchy Manufacturing Business Names:

- List of the Best Marketing Ideas For Your Manufacturing Business:

How to Write a Manufacturing Business Plan in 7 Steps:

1. describe the purpose of your manufacturing business..

The first step to writing your business plan is to describe the purpose of your manufacturing business. This includes describing why you are starting this type of business, and what problems it will solve for customers. This is a quick way to get your mind thinking about the customers’ problems. It also helps you identify what makes your business different from others in its industry.

It also helps to include a vision statement so that readers can understand what type of company you want to build.

Here is an example of a purpose mission statement for a manufacturing business:

Our mission at [Company Name] is to be the premier provider of innovative, high-quality manufacturing solutions that meet our customers' needs, while delivering superior customer service and providing a safe and rewarding workplace for our employees.

2. Products & Services Offered by Your Manufacturing Business.

The next step is to outline your products and services for your manufacturing business.

When you think about the products and services that you offer, it's helpful to ask yourself the following questions:

- What is my business?

- What are the products and/or services that I offer?

- Why am I offering these particular products and/or services?

- How do I differentiate myself from competitors with similar offerings?

- How will I market my products and services?

You may want to do a comparison of your business plan against those of other competitors in the area, or even with online reviews. This way, you can find out what people like about them and what they don’t like, so that you can either improve upon their offerings or avoid doing so altogether.

3. Build a Creative Marketing Stratgey.

If you don't have a marketing plan for your manufacturing business, it's time to write one. Your marketing plan should be part of your business plan and be a roadmap to your goals.

A good marketing plan for your manufacturing business includes the following elements:

Target market

- Who is your target market?

- What do these customers have in common?

- How many of them are there?

- How can you best reach them with your message or product?

Customer base

- Who are your current customers?

- Where did they come from (i.e., referrals)?

- How can their experience with your manufacturing business help make them repeat customers, consumers, visitors, subscribers, or advocates for other people in their network or industry who might also benefit from using this service, product, or brand?

Product or service description

- How does it work, what features does it have, and what are its benefits?

- Can anyone use this product or service regardless of age or gender?

- Can anyone visually see themselves using this product or service?

- How will they feel when they do so? If so, how long will the feeling last after purchasing (or trying) the product/service for the first time?

Competitive analysis

- Which companies are competing with yours today (and why)?

- Which ones may enter into competition with yours tomorrow if they find out about it now through word-of-mouth advertising; social media networks; friends' recommendations; etc.)

- What specific advantages does each competitor offer over yours currently?

Marketing channels

- Which marketing channel do you intend to leverage to attract new customers?

- What is your estimated marketing budget needed?

- What is the projected cost to acquire a new customer?

- How many of your customers do you instead will return?

Form an LLC in your state!

4. Write Your Operational Plan.

Next, you'll need to build your operational plan. This section describes the type of business you'll be running, and includes the steps involved in your operations.

In it, you should list:

- The equipment and facilities needed

- Who will be involved in the business (employees, contractors)

- Financial requirements for each step

- Milestones & KPIs

- Location of your business

- Zoning & permits required for the business

What equipment, supplies, or permits are needed to run a manufacturing business?

- Manufacturing equipment

- Raw materials

- Safety equipment and supplies

- Labor and skilled workers

- Legal permits and licensing as required by local ordinance

5. Management & Organization of Your Manufacturing Business.

The second part of your manufacturing business plan is to develop a management and organization section.

This section will cover all of the following:

- How many employees you need in order to run your manufacturing business. This should include the roles they will play (for example, one person may be responsible for managing administrative duties while another might be in charge of customer service).

- The structure of your management team. The higher-ups like yourself should be able to delegate tasks through lower-level managers who are directly responsible for their given department (inventory and sales, etc.).

- How you’re going to make sure that everyone on board is doing their job well. You’ll want check-ins with employees regularly so they have time to ask questions or voice concerns if needed; this also gives you time to offer support where necessary while staying informed on how things are going within individual departments too!

6. Manufacturing Business Startup Expenses & Captial Needed.

This section should be broken down by month and year. If you are still in the planning stage of your business, it may be helpful to estimate how much money will be needed each month until you reach profitability.

Typically, expenses for your business can be broken into a few basic categories:

Startup Costs

Startup costs are typically the first expenses you will incur when beginning an enterprise. These include legal fees, accounting expenses, and other costs associated with getting your business off the ground. The amount of money needed to start a manufacturing business varies based on many different variables, but below are a few different types of startup costs for a manufacturing business.

Running & Operating Costs

Running costs refer to ongoing expenses related directly with operating your business over time like electricity bills or salaries paid out each month. These types of expenses will vary greatly depending on multiple variables such as location, team size, utility costs, etc.

Marketing & Sales Expenses

You should include any costs associated with marketing and sales, such as advertising and promotions, website design or maintenance. Also, consider any additional expenses that may be incurred if you decide to launch a new product or service line. For example, if your manufacturing business has an existing website that needs an upgrade in order to sell more products or services, then this should be listed here.

7. Financial Plan & Projections

A financial plan is an important part of any business plan, as it outlines how the business will generate revenue and profit, and how it will use that profit to grow and sustain itself. To devise a financial plan for your manufacturing business, you will need to consider a number of factors, including your start-up costs, operating costs, projected revenue, and expenses.

Here are some steps you can follow to devise a financial plan for your manufacturing business plan:

- Determine your start-up costs: This will include the cost of purchasing or leasing the space where you will operate your business, as well as the cost of buying or leasing any equipment or supplies that you need to start the business.

- Estimate your operating costs: Operating costs will include utilities, such as electricity, gas, and water, as well as labor costs for employees, if any, and the cost of purchasing any materials or supplies that you will need to run your business.

- Project your revenue: To project your revenue, you will need to consider the number of customers you expect to have and the average amount they will spend on each visit. You can use this information to estimate how much money you will make from selling your products or services.

- Estimate your expenses: In addition to your operating costs, you will need to consider other expenses, such as insurance, marketing, and maintenance. You will also need to set aside money for taxes and other fees.

- Create a budget: Once you have estimated your start-up costs, operating costs, revenue, and expenses, you can use this information to create a budget for your business. This will help you to see how much money you will need to start the business, and how much profit you can expect to make.

- Develop a plan for using your profit: Finally, you will need to decide how you will use your profit to grow and sustain your business. This might include investing in new equipment, expanding the business, or saving for a rainy day.

Frequently Asked Questions About Manufacturing Business Plans:

Why do you need a business plan for a manufacturing business.

A business plan for a manufacturing business is essential because it serves as a guide to help the business plan its activities and reach its desired goals. It provides important information such as market analysis, strategy, financial projections, and operational plans. Additionally, it can serve as an important tool to attract potential investors or lenders and help secure funding.

Who should you ask for help with your manufacturing business plan?

You should consult a qualified business consultant, accountant, and/or lawyer who specialise in assisting companies with their manufacturing business plans. Additionally, it is a good idea to reach out to trade organisations, industry bodies, and experts in the manufacturing sector for guidance.

Can you write a manufacturing business plan yourself?

Yes, you can write a manufacturing business plan yourself. Depending on the complexity of your plan, you may want to research best practices and consult experts in the field if necessary. When writing a manufacturing business plan, it is important to include a market analysis, competitive analysis, operations plan, financial projections, and strategic plan. Additionally, you should also include key objectives, milestones and management strategies.

Related Business Plans

Home Inventory Business Plan Template & Guidebook

Home Inspection Business Plan Template & Guidebook

Home Decor Business Plan Template & Guidebook

Health And Wellness Business Plan Template & Guidebook

Hauling Business Plan Template & Guidebook

Hardware Business Plan Template & Guidebook

Handyman Business Plan Template & Guidebook

Hair Extension Business Plan Template & Guidebook

Handbag Business Plan Template & Guidebook

I'm Nick, co-founder of newfoundr.com, dedicated to helping aspiring entrepreneurs succeed. As a small business owner with over five years of experience, I have garnered valuable knowledge and insights across a diverse range of industries. My passion for entrepreneurship drives me to share my expertise with aspiring entrepreneurs, empowering them to turn their business dreams into reality.

Through meticulous research and firsthand experience, I uncover the essential steps, software, tools, and costs associated with launching and maintaining a successful business. By demystifying the complexities of entrepreneurship, I provide the guidance and support needed for others to embark on their journey with confidence.

From assessing market viability and formulating business plans to selecting the right technology and navigating the financial landscape, I am dedicated to helping fellow entrepreneurs overcome challenges and unlock their full potential. As a steadfast advocate for small business success, my mission is to pave the way for a new generation of innovative and driven entrepreneurs who are ready to make their mark on the world.

Manufacturing Business Plan Template

What is a Manufacturing Business Plan?

A manufacturing business plan outlines the objectives, initiatives, and goals of a manufacturing business. It is used to guide the development and execution of a business strategy and to monitor progress towards achieving desired goals. The plan should address all aspects of the business, including marketing, production, personnel, operations, and financials.

What's included in this Manufacturing Business Plan template?

- 3 focus areas

- 6 objectives

Each focus area has its own objectives, projects, and KPIs to ensure that the strategy is comprehensive and effective.

Who is the Manufacturing Business Plan template for?

This Manufacturing Business Plan template is designed to help manufacturers of all sizes and industries create a plan to launch, run and grow their business. It provides a framework to clearly define and measure the objectives, actions, and measurements that are necessary for success.

1. Define clear examples of your focus areas

A focus area is an area of your business that requires extra attention in order to achieve success. Examples of focus areas can include increasing operational efficiency, improving product quality, or strengthening financial management.

2. Think about the objectives that could fall under that focus area

An objective is a goal that you want to achieve within a specific focus area. For example, under the focus area of operational efficiency, the objective could be to reduce shipping wait time.

3. Set measurable targets (KPIs) to tackle the objective

KPIs, or key performance indicators, are metrics that help to measure the success of the objectives. For example, to measure the success of the objective to reduce shipping wait time, the KPI would be to decrease the average shipping wait time by 30%.

4. Implement related projects to achieve the KPIs

Projects, or actions, are the steps necessary to achieve the KPIs. For example, to achieve the KPI of reducing the average shipping wait time, the action would be to analyze the current shipping process.

5. Utilize Cascade Strategy Execution Platform to see faster results from your strategy

Cascade is a strategy execution platform that makes it easy to plan, implement, and track progress towards achieving your manufacturing business plan. With Cascade, you can create strategies, assign tasks, track progress, and quickly see the results of your efforts.

Manufacturing Business Plan Template [Updated 2024]

Manufacturing Business Plan Template

If you want to start a Manufacturing business or expand your current Manufacturing company, you need a business plan.

The following Manufacturing business plan template gives you the key elements to include in a winning Manufacturing business plan.

You can download our business plan template (including a full, customizable financial model) to your computer here.

Below are links to each of the key sections of a sample manufacturing business plan. Once you create your plan, download it to PDF to show banks and investors.

I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

Comments are closed.

Manufacturing Business Plan Home I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

Business Plan Template for Manufacturing Company

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

Starting a manufacturing company can be an exciting but challenging endeavor. To ensure success, you need a solid business plan that covers all the essential aspects of your operations. That's where ClickUp's Business Plan Template for Manufacturing Companies comes in!

Our template provides a comprehensive framework for outlining your company's goals, conducting market analysis, projecting finances, and strategizing your operations. With ClickUp's Business Plan Template, you'll be able to:

- Clearly define your company's vision, mission, and objectives

- Conduct a thorough market analysis to understand your target audience and competitors

- Develop financial projections and budgets to secure funding and attract investors

- Create operational strategies to optimize production, logistics, and quality control

Whether you're a seasoned entrepreneur or just starting out, our Business Plan Template will guide you through the process of building a successful manufacturing company. Don't miss out on the opportunity to turn your vision into reality—get started with ClickUp today!

Business Plan Template for Manufacturing Company Benefits

Creating a solid business plan is crucial for success in the manufacturing industry. By using the Business Plan Template for Manufacturing Company, you can:

- Clearly define your company's vision, mission, and goals

- Conduct a thorough market analysis to identify target customers and competitors

- Develop a comprehensive financial plan, including revenue projections and cost analysis

- Outline your manufacturing processes, supply chain management, and quality control measures

- Present a professional and well-structured document to potential investors and lenders

- Guide strategic decision-making and ensure alignment with your long-term objectives

- Monitor and track progress towards your business milestones and objectives

Main Elements of Manufacturing Company Business Plan Template

When it comes to creating a comprehensive business plan for your manufacturing company, ClickUp has you covered with its Business Plan Template. Here are the main elements you'll find in this template:

- Custom Statuses: Keep track of the progress of different sections of your business plan with statuses like Complete, In Progress, Needs Revision, and To Do.

- Custom Fields: Add important details to your business plan using custom fields such as Reference, Approved, and Section, allowing you to easily organize and categorize information.

- Custom Views: Access different perspectives of your business plan using views like Topics, Status, Timeline, Business Plan, and Getting Started Guide, making it easy to navigate and present your plan effectively.

- Document Collaboration: Collaborate with your team in real-time using ClickUp's Docs feature to work together on your business plan.

- Task Management: Break down your business plan into actionable tasks, assign them to team members, set due dates, and track progress using ClickUp's powerful task management features.

How To Use Business Plan Template for Manufacturing Company

If you're looking to create a business plan for your manufacturing company, follow these 6 steps using ClickUp's Business Plan Template:

1. Define your company's mission and vision

Start by clearly defining the mission and vision of your manufacturing company. What do you aim to achieve and how do you plan to do it? This will serve as the guiding principles for your business plan.

Use a Doc in ClickUp to outline your company's mission and vision statements.

2. Conduct market research

Thorough market research is essential to understand your target audience, competitors, and industry trends. Identify your niche, analyze customer needs, and assess the competitive landscape. This will help you position your manufacturing company effectively.

Use the Table view in ClickUp to compile and analyze market data, including customer demographics, competitor analysis, and industry trends.

3. Develop your product offerings

Outline the products and services your manufacturing company will offer. Determine the unique selling points of your offerings and how they address customer needs. Consider factors such as pricing, quality, and delivery timelines.

Use tasks in ClickUp to create a product development plan and assign tasks to team members responsible for designing, manufacturing, and testing the products.

4. Create a marketing and sales strategy

Define your marketing and sales strategies to promote your manufacturing company. Identify the channels and tactics you will use to reach your target audience. This may include digital marketing, trade shows, partnerships, or direct sales.

Use Goals in ClickUp to set specific marketing and sales objectives, such as lead generation targets or revenue goals.

5. Establish operational processes

Develop a plan for your manufacturing processes, including procurement, production, quality control, and logistics. Define the roles and responsibilities of your team members and ensure smooth coordination across departments.

Use Automations in ClickUp to streamline your operational processes by automating repetitive tasks and setting up notifications for key milestones.

6. Create financial projections

Project your financials, including revenue, expenses, and cash flow projections for the next few years. Consider factors such as production costs, pricing, sales volume, and market demand. This will help you assess the viability and profitability of your manufacturing company.

Use Dashboards in ClickUp to track and visualize your financial projections, allowing you to monitor your company's performance and make informed decisions.

By following these steps and utilizing ClickUp's Business Plan Template, you'll be well-equipped to create a comprehensive and effective business plan for your manufacturing company.

Get Started with ClickUp’s Business Plan Template for Manufacturing Company

Entrepreneurs and business owners in the manufacturing industry can use the Business Plan Template for Manufacturing Company to create a comprehensive plan for their business.

First, hit "Add Template" to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you'd like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to create a solid business plan:

- Use the Topics View to outline and organize the different sections of your business plan, such as Executive Summary, Market Analysis, Financial Projections, and Operational Strategies.

- The Status View will help you track the progress of each section, with statuses like Complete, In Progress, Needs Revision, and To Do.

- The Timeline View will allow you to set deadlines and visualize the timeline for completing each section of your business plan.

- Use the Business Plan View to have a comprehensive overview of your entire plan, with all the sections and details in one place.

- The Getting Started Guide View will provide you with step-by-step instructions and tips on how to effectively use the template and create a successful business plan.

- Customize the template by adding custom fields like Reference, Approved, and Section to provide additional information and track important details.

- Update statuses and custom fields as you make progress and receive feedback from stakeholders.

- Monitor and analyze your business plan to ensure it aligns with your goals and attracts investors.

- Business Plan Template for Distance Learning

- Business Plan Template for Medication Errors