Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 04 October 2021

AI-based design of a nuclear reactor core

- Vladimir Sobes 1 ,

- Briana Hiscox 2 ,

- Emilian Popov 2 ,

- Rick Archibald 2 ,

- Cory Hauck 2 ,

- Ben Betzler 2 &

- Kurt Terrani 3

Scientific Reports volume 11 , Article number: 19646 ( 2021 ) Cite this article

6881 Accesses

11 Citations

Metrics details

- Applied mathematics

- Computational science

- Energy science and technology

- Engineering

- Mathematics and computing

- Nuclear energy

- Power stations

- Scientific data

The authors developed an artificial intelligence (AI)-based algorithm for the design and optimization of a nuclear reactor core based on a flexible geometry and demonstrated a 3× improvement in the selected performance metric: temperature peaking factor. The rapid development of advanced, and specifically, additive manufacturing (3-D printing) and its introduction into advanced nuclear core design through the Transformational Challenge Reactor program have presented the opportunity to explore the arbitrary geometry design of nuclear-heated structures. The primary challenge is that the arbitrary geometry design space is vast and requires the computational evaluation of many candidate designs, and the multiphysics simulation of nuclear systems is very time-intensive. Therefore, the authors developed a machine learning-based multiphysics emulator and evaluated thousands of candidate geometries on Summit, Oak Ridge National Laboratory’s leadership class supercomputer. The results presented in this work demonstrate temperature distribution smoothing in a nuclear reactor core through the manipulation of the geometry, which is traditionally achieved in light water reactors through variable assembly loading in the axial direction and fuel shuffling during refueling in the radial direction. The conclusions discuss the future implications for nuclear systems design with arbitrary geometry and the potential for AI-based autonomous design algorithms.

Similar content being viewed by others

A high-density and high-confinement tokamak plasma regime for fusion energy

Engineering is evolution: a perspective on design processes to engineer biology

Clarifying the four core effects of high-entropy materials

Introduction.

The rapid development of advanced manufacturing and its application to advanced reactor design in the Transformational Challenge Reactor (TCR) program 1 have presented the opportunity to explore the potential revolutionary benefits of the arbitrary geometry design of nuclear systems. Nuclear engineering design is no longer bound to the simple geometries manufacturable by traditional methods, slabs, cylinders, and spheres (e.g., fuel plates, fuel pellets, fuel pebbles) 2 , 3 . However, the increased freedom of designing an arbitrary geometry system comes at the cost of an increased complexity in design optimization. Dimensionality quickly makes the design problem overwhelming for engineers. To address this issue, the authors implemented an artificial intelligence (AI)-based optimization algorithm and established a challenge problem to demonstrate the application.

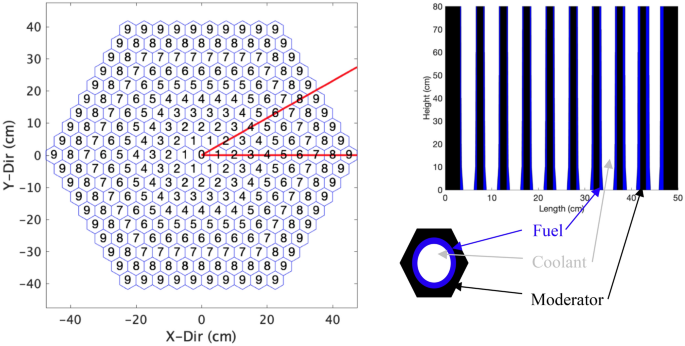

The basis of the challenge problem is to determine the optimal geometric shape in the axial dimension of the cooling channels of a simplified reactor design’s full-core model. The reactor core used in this AI design optimization is based on a simplification of the design of the actual TCR core. The core is a right cylinder that is 1 m in diameter and 80 cm tall. Nine concentric rings of hexagonal assemblies surround a central hexagonal assembly. The fuel compact of traditional TRISO particles is an annular design with a 2.5 cm outer diameter, and sits in the middle of each 5 cm wide (flat to flat) hexagonal assembly. There are cooling channels inside the annular fuel, and an yttrium-hydride the moderator surrounds the outside of the fuel annulus. The center assembly in the core is pure moderator, uncooled and unfueled. The helium coolant flows from the bottom to the top in all the fueled assemblies. Figure 1 presents a core schematic.

The top view of the core is shown on the left with the nine radial assembly rings labeled. Only the symmetric 1/12 segment inside the red lines is modeled. A horizontal slice of one assembly and an axial cross section of the optimized core configuration is shown on the right. Created using MATLAB R2020b, www.mathworks.com .

The design space encompassed the axial profile of the coolant channel in each of the nine assembly radial rings. That is, all the assemblies in each ring had the same axial coolant channel profile, but the coolant channel profile was different for each radial assembly ring. The geometry optimization was parametrized by a set of coolant channel radii. Each of the nine assembly radial rings had an independent set of nine coolant channel radii which spanned the 80 cm height of the core in 10 cm vertical segments. The radium of the coolant channel was a piece-wise linear function connecting these nine radii for each assembly. The maximum coolant channel radius was constrained to be greater than 1 mm and 2.4 cm (1 mm less than the fuel outer radius).

The objective for this core design was to minimize the temperature peaking factor across each 10 cm vertical segment (eight making the full axial height) of each assembly while maintaining a critical core configuration. The engineering justification for this objective function was to minimize the mechanical stresses due to temperature gradients in the components, although no thermomechanical analyses were performed in this initial study. Specifically, the objective function is defined as:

where \(T\left(x,y,z,\Phi \right)\) is the temperature at the location \(\left(x,y,z\right)\) and design parameters \(\Phi\) .

The challenge problem inherently requires multiphysics modeling between neutron transport and thermofluidics. The problem is further convoluted because the cooling channel radius (axially variable) simultaneously controls everything about the heat transfer process and the amount of fuel at each axial core level because the fuel annulus outer diameter is fixed. The predictive simulation of candidate configurations requires computationally intensive modeling. The authors used a Monte Carlo-based code for neutron transport coupled to a computational fluid dynamics (CFD) code for the thermofluidics. With a large potential design space to explore, it was impractical to evaluate all of the candidate designs with the full fidelity physics. Therefore, the authors developed a machine learning (ML)-based multiphysics emulator that was designed to run on Summit, Oak Ridge National Laboratory’s (ORNL’s) GPU-based high-performance computing (HPC) system 4 . By training the ML-based emulator, the authors achieved errors as low as a few percent, which allowed them to quickly and reliably sample thousands of candidate designs on Summit. Only the most promising candidate designs were tested with the full-fidelity physics simulations. The emulator was updated, and convergence on the optimal design was achieved in only a few iterations.

The “ Background ” section reviews of some of the previous attempts at AI-based nuclear reactor design and optimization that did not leverage the advantages of arbitrary geometry. The section also discusses designing ML-based emulators for computationally intensive full-fidelity modeling software. The “ Methods ” section describes the overall workflow of the authors’ approach and presents the details of the full-fidelity modeling, the design of the emulator, and the optimization approach used on Summit. The “ Results ” section presents and discusses the optimal design solution to the challenge problem. Lastly, the “ Discussion ” section concludes with the authors’ outlook on the future of nuclear systems design in arbitrary geometry and discusses how the AI-based nuclear systems design approach can supplement the toolbox of nuclear industry designers.

Today, reactor cores are built from industrial materials that represent regular (i.e., usually cylindrical or plate) component geometries. The reactor cores have a periodic structure; for example, one component (i.e., core fuel element) is repeated multiple times to create the entire core. This approach results in geometrically similar fuel elements with a regular shape 5 . The fuel volumetric (per unit volume of core) content is spatially uniform. This limitation causes complications and results in fuel usage with different enrichment to efficiently design the entire core, minimizing power and thermal gradients. Similar observations can be made regarding the hydraulic design. The core is cooled to remove heat and generate power. The periodic repeatable fuel structure imminently produces the same regular coolant channel configuration (e.g., all coolant channels are the same and will produce the same level of cooling under the same conditions). The background of this research assumes an additively manufactured core in which the fuel and cooling channel geometries have practically unlimited spatial degrees of freedom. This is the primary difference explored in this work, and it might bring unforeseen performance that could be hidden from designers but easily discoverable for an unbiased AI algorithm.

Previous attempts at AI-based design and optimization of nuclear reactor cores are found in other works; e.g. References 6 , 7 , 8 , 9 , 10 , 11 , 12 , 13 . One common theme among these earlier works is that the optimization problem is posed as a combinatorial problem with fixed geometry rather than as an optimization over continuously variable geometry parametrization. One example is the fuel shuffling during the reloading of a boiling water reactor core. Genetic algorithms have been the predominant choice of AI algorithms for the combinatorial optimization problem. When more continuous variable geometries were studied, more structured optimization approaches were used 14 . A recent work considered the nuclear systems design by using genetic algorithms created from scratch rather than an optimization of an existing configuration 15 . However, arbitrary geometry could only be considered through a voxel representation. Lastly, the authors had published on the framework for an arbitrary geometry optimization of nuclear systems and gave some demonstrations on simplified challenge problems 2 . This work is the application of that framework to a nuclear reactor full core.

The mathematical formulations and their solutions for the underlying multiphysics phenomena that occur in the reactor core are well-known. For this work, the focus in on solutions of the Boltzmann transport equation, which will be the driving term to Poisson’s equation coupled with the Navier–Stokes equations. The solution to this set of coupled equations in nuclear engineering is tied up in several complex computer codes and is computationally intensive. Therefore, an efficient multiparameter optimization search using high-fidelity physics models is prohibitively expensive. In this work, the authors explored the automatic construction of physics-informed ML methods by using emulators with validation from very sparse sampling of the predictive high-fidelity physics simulations. The physics-informed emulators are based on a steady-state reduced-order model through Gaussian kernel convolution that allows for a fast evaluation on a single GPU 16 , which is suitable for ideal scalability in the search over the vast design space.

Surrogate modeling is a well-used method in science and engineering 17 . The fundamental approach is to approximate quantities of interest from complex systems by using cost-effective and accurate surrogates that otherwise could only be measured or simulated at very high cost, if at all. Within the context of design optimization, building cost-effective and accurate surrogates enables the exploration of complicated design space, accelerating the process of finding the best designs for given loss functions. The surrogate modeling method that the authors developed in this work falls under the category of multi-fidelity surrogate modeling. The authors merged the information generated by the dense sampling of reduced-order modeling with sparse full physics simulation via Gaussian processes (GPs) 18 . This work uniquely developed reduced-order models of the neutronics and thermofluidic physics that were designed for a fast evaluation on a single GPU. Thus, it is possible to evaluate millions of designs by using GPU-based HPC systems, such as Summit 4 .

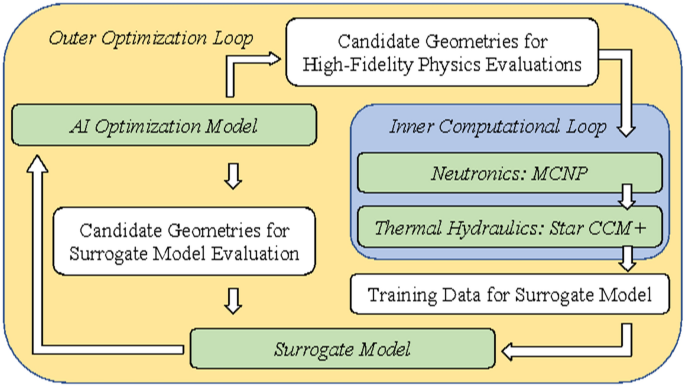

Optimization work flow: inner and outer loops

The authors identified two categories of tasks necessary for successfully developing a holistic AI-based approach to computationally optimizing nuclear systems. The tasks are separated into the inner computational loop and the outer optimization loop. The inner computational loop involves the full-fidelity physics simulation of the candidate designs needed to create the training data for the multiphysics ML-based emulator. The outer optimization loop begins with training the emulator based on the results generated with the full-fidelity physics calculations, and design parameters are chosen from a random sample of the design space. The outer optimization loop is the AI model for the design space that is updated based on massively parallel evaluations of the multiphysics emulator on thousands of candidate geometries. Figure 2 illustrates the workflow. The outer loop can be thought of as an adaptive sampling method, ubiquitous in computation design 17 , where each iteration focuses on a smaller design space that minimizes the given loss function.

Illustration of the AI optimization workflow. Created using Microsoft PowerPoint, version 16.52, www.microsoft.com .

Inner computational loop

The neutronic modeling for this project was conducted in the Monte Carlo N-Particle code 19 . This code was chosen due to its ability to calculate power in nonfuel materials. This allowed for a very accurate power density profile in all materials. To save on computational time, the model was 30° of the full core (1/12) with reflective boundary conditions (i.e., instead of the full 360°). Because of the intrinsic symmetry and core optimization variables, this model represents a full-core model. The model was run with four tally meshes to account for the energy deposition in a cell from neutrons and photons in the fuel and moderator materials. A tally was produced for each mesh bin. The mesh bin density was 504 in the x direction, 252 in the y direction, and 20 in the z direction. Therefore, the lengths of each mesh bin were 0.1, 0.1, and 4 cm. These sizes were determined because they have a reasonable computational cost neutronically and thermofluidically, and meshing studies determined that they were sufficiently fine to achieve good resolution on the fuel annulus and coolant channels.

There were 750 cycles run with 10,000 particles in each cycle. The first 50 cycles were inactive which means they were not taken into account for the determination of k-effective, flux, or reaction rates. It is necessary to have inactive cycles in the beginning of a Monte Carlo simulation to converge the fission source. The average standard deviation of k-effective was 0.00024 and the maximum was 0.00030. The power density was normalized to maintain a constant core power of 3 MW. MCNP was run in “mode N P” which accounts for neutron-induced photons. This is necessary for the photon-heating tallies.

The thermofluidics model developed for this work relies on numerical methods (e.g., temporal and spatial discretization) and physical models (e.g., turbulent flow, conjugate heat transfer) to predict the temperature and flow distribution in the geometry of interest. The inherent assumptions of these methods and models must be quantified to ensure the correctness and accuracy of the results. In view of the diverse geometry configurations of the optimized designs, an accurate prediction of temperature distribution in the component is necessary. The thermofluidic model must be capable of computing a conjugate (i.e., solid fluid) heat transfer in arbitrary geometric shapes. To achieve this, a CFD approach was taken, and the commercial software STAR-CCM+ was used 20 . This method allows complex surfaces to be discretized with finite volume techniques, as well as allows the interface between the solid structure and the coolant—gas, in this case—to be properly defined. On the solid side, a thermal diffusion of heat with a volumetric heat source is computed to determine the temperature distribution. The heat generated by nuclear fission is deposited in the core element according to the volumetric power distribution supplied by the reactor physics calculation.

On the fluid side, a Reynolds averaging of the velocity vector field was employed within the finite volume formulation. Since the assumed flow is highly turbulent, a two-equation model of turbulence, realizable k-epsilon, was used. This model is better than the standard k-epsilon model for many applications, including rotational and shear flows, and it generally gives answers that are at least as accurate 21 . The near-wall velocity field is resolved with the two-layer all wye (Y) plus method 20 . All these models accurately predict the wall heat transfer, which is critical for the proper resolution of component temperature field.

To model the geometry variation necessary for running the suite of optimization codes, a geometry parameterization method was used. Within the CFD computation, the geometry is regenerated automatically every time a new combination of parameters is tried. The software allows the computational domain to be modified—both in its geometry and discretization—without user intervention. This is achieved by automating the computing process with Java drivers. The approach is fully integrable in an autonomous workflow within the entire optimization suite.

For the thermofluidic calculation, the domain was discretized with a variable resolution but with at least four elements in the radial direction across fuel. It was meshed with a polyhedral mesh with a base dimension determined by the smallest fuel element. Because the geometry varies by fuel and channel sizes, the number of elements per each case is different and usually stays below 7 million. Some specific cases with thin fuel might increase the element count to 20 million, but this is rare. The calculations were run in parallel on 16 processes, and most run time is spent on grid generation. The average clock time for a single run is around 2 h. The cases are run until the convergence of momentum and energy residuals for at least three orders of magnitude is achieved. Sensitivity on mesh and residuals convergence was performed to allow for temperature accuracy of less than 1° to be achieved. The employed modeling approach relies on component physics validation which is part of the software qualification process implemented at ORNL. The flow and heat transfer solutions, and the corresponding modeling techniques, were initially tested and verified by standard test problems. The models will be further tested against integral experiments after such are carried out as part of a comprehensive testing program.

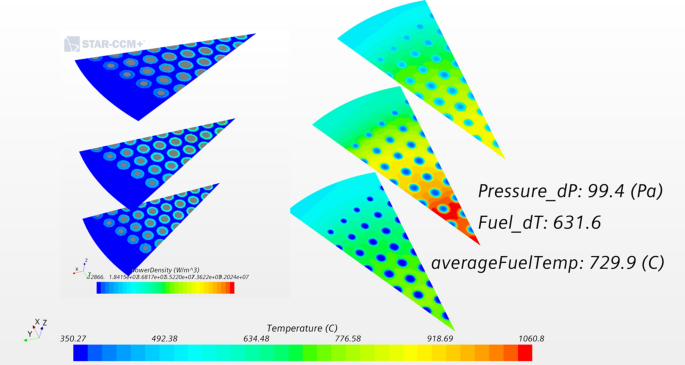

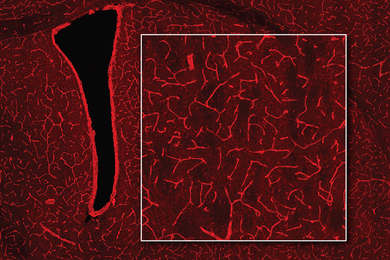

Figure 3 illustrates a typical result from the thermofluidic solution. Contours of temperatures are shown at three axial levels in the core: low (15 cm), middle (45 cm), and top (75 cm). The highest temperature is reached on the fuel-moderator boundary because the design does not involve extra moderator cooling and because the power deposited in the moderator is removed only through fuel-cooling channels. The radial variation of cooling channels is clearly visible, as defined by the optimization algorithm. Channels are larger in the central part and smaller at the periphery where the power density is lower and less coolant is needed. The average pressure drop and fuel temperature and the maximum fuel temperature difference were also calculated and are provided for reference. The input power density is plotted on the left side of Fig. 3 at the same axial positions. The simulation uses power deposition in the fuel and moderator. The power plot gives some impression for the fuel thickness variation (light blue color) with more fuel toward the periphery and less in the middle of core. Although not evident from the limited axial locations plotted, the fuel and channel sizes also vary axially as eight piece-wise linear sections (Fig. 1 ).

Temperature field from the thermofluidic solution. Three axial sections are plotted at lower, middle, and upper core element levels. They show the temperatures in the coolant, fuel, and moderator. On the left, the power input to the fuel and moderator is provided for reference. Both fuel and channel sizes vary in the radial direction. Created using Star-CCM+, version 2020.1, www.plm.automation.siemens.com/global/en/products/simcenter/STAR-CCM.html .

Outer optimization loop

Simulation-based computational design can quickly become an intractable problem, depending on the size of the computational design space and computational complexity of the design simulation. The authors developed reduced-order surrogate models for neutronics and thermofluidics that can quickly sample hundreds of thousands of geometries on Summit. By using the combination of surrogate modeling and sparse validation with correction from full-physics simulation, the authors were able to train GP ML methods to accurately predict optimal designs. On average, one reactor core design takes ~ 150 s for the reduced-order surrogate model to simulate on a single Summit GPU. This time includes all setup costs and data movement. With six GPUs per node, the authors were able to test ~ 150 reactor geometries per hour per node. Generally, the surrogate is around 95% accurate compared with full physics simulations that use relative least square error measure on the objective function for this problem. Also, the surrogate model generally struggles the most at the inlet region. For the core challenge problem, Summit simulated ~ 10,000 different geometries in combination with ~ 100 full physics simulations in four iterations to determine an optimal design. We provide the code in the supplemental materials for this paper.

The outer loop AI model is based upon Gaussian processes, which are a kernel-based machine learning method that provides an efficient method for ML applicable to physics-oriented problems in engineering sciences. Specifically, given a set,

of training data the loss can be determined for any parameter set. Here, x is the position vector, and \({p}_{i}\) is the parameter vector for the i th design. The functions are the power \({P}_{i}\) , component temperature \({T}_{i}\) , fractional coolant indicator \({V}_{i,c}\) , fractional fuel indicator \({V}_{i,f}\) , and fractional moderator indicator \({V}_{i,m}\) for the N simulated training sets. The loss \({L}_{i}\) for any design is defined to be the standard deviation of temperature for every domain with positive fuel indicator. The last item in this collection is the error estimation of the loss \({\sigma }_{i}\) . The loss of any design \(p\) is predicted by using the kernel-based ML method defined as:

where kernel function, \(k\left(p,{p}_{i}\right)={e}^{-\frac{1}{2}{\| p-{p}_{i}\| }^{2}}\) is used. The coefficients of the kernel-based ML are found by solving

for \(j=1,...,N\) training sets, where L j losses are known. The matrix elements are given as \({K}_{i,j}=k\left({p}_{i},{p}_{j}\right)\) for \(1\le i,j\le N\) and the coefficient vector \(c=\left({c}_{1},...,{c}_{N}\right)\) .

The data from the full-fidelity physic model are augmented with a set of M emulated models:

The ML method assumes that the full fidelity physical models are exact, or \({\sigma }_{i}=0\) for \(i=1,...,N\) . In the case of \(i=N+1,...,N+M\) , a low-resolution approximation of the physics is used to estimate the temperature function \(\tilde{T }\) by solving:

where \({\upsilon }_{i}\left(x\right)\) is a flow field, \(\frac{\partial {\tilde{T }}_{i}\left(x\right)}{\partial x}\) is the temperature gradient along the flow direction, and \({\alpha }_{c}\) , \({\alpha }_{f}\) , and \({\alpha }_{m}\) are constants. For any design \(p\) , the flow field is calculated based on the volumetric rate of coolant. The flow field is zero in the solid material of the reactor. The flow field and constants \({\alpha }_{c}\) , \({\alpha }_{f}\) , and \({\alpha }_{m}\) are calculated such that \({\sum }_{i=1}^{N}{\| {T}_{i}\left(x\right)-{\tilde{T }}_{i}\left(x\right)\| }_{2}\) is minimized, where T i (x) is the training set temperatures.

When the data are augmented, the Gaussian process is calculated by:

where the kernel function, \(k\left(p,{p}_{i}\right)={e}^{-\frac{1}{2}{\| p-{p}_{i}\| }^{2}}\) is used. The coefficients of the kernel-based ML are found by solving

for \(j=1,...,N+M\) and \({\sigma }_{i}=0\) for \(i\le N\) , where the matrix elements are given as \({K}_{i,j}=k\left({p}_{i},{p}_{j}\right)\) for \(1\le i,j\le N+M\) , the coefficient vector \(c=\left({c}_{1},...,{c}_{N+M}\right)\) , and σ i is an estimate for the error in the emulation.

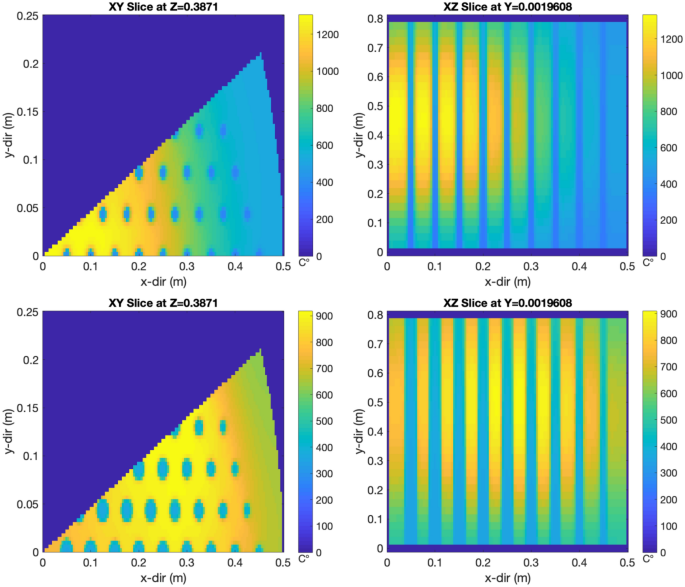

The quantitative objective function for the challenge problem’s optimization design was to minimize the temperature peaking in each 10 cm axial section (eight total for the full-core height) of each assembly in the core. From single-assembly simulations, the average numerical value of the objective function for a conventional design with axially uniform coolant channels of one radius was 842.1 ℃. The optimal design results in a final value of the objective function of 291.35 ℃; a 3× improvement in the objective function is achieved through the AI-based optimization of the geometry of the cooling channels when compared to the constant-cooling-channel-radius design. Figure 4 presents the visualization of the calculated temperature distribution in the core before and after the optimization.

Visual representation of the temperature distribution in the original (top) and optimized (bottom) cores. The left two figures present a radial slice at an axial location of 38.7 cm out of a total core height of 80 cm. The right two figures present an axial slice through the core. Created using MATLAB R2020b, www.mathworks.com .

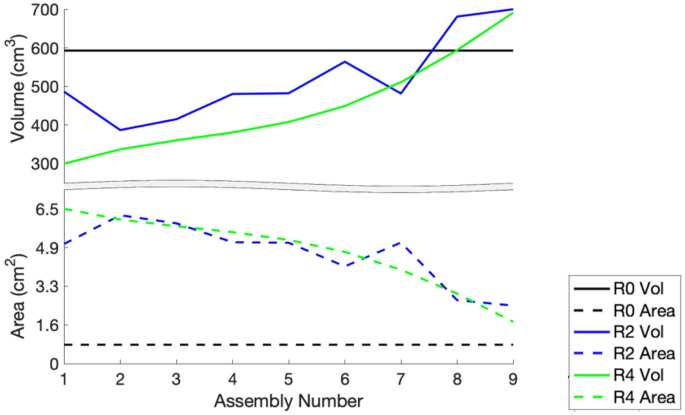

Figure 5 presents a physical interpretation of the optimization results by plotting the volume of the fuel in each assembly and the heat-exchange area for the cooling channels. The initial configuration with axially uniform cooling channels in all assemblies is given in black. This presents the optimal solution for a uniform cooling channel configuration. An intermediate stage of the optimization process is shown in blue, and the final, optimal design is presented in green. The intermediate result can be identified by the non-smooth behavior of the volume and surface plots across the nine radial assembly rings, whereas the converged solution displays the physically expected smooth behavior. Furthermore, there is a trade-off between the increased heat-exchange area of the cooling channel and the reduced fuel volume. Both contribute in the same direction to reducing the temperature peaking in the middle of the core that is observed with the uniform cooling channel design.

Plot of the fuel volume per assembly (top) and the heat-exchange area for the cooling channel in each assembly (bottom). The three different colors represent different iterations of the optimization algorithm: initial (R0) and two later iterations (R2 and R4). Here, R0, R2, and R4 are shorthand for iteration round zero, two, and four, respectively. Created using MATLAB R2020b, www.mathworks.com .

Although the optimal configuration can be justified from an engineering analysis perspective, the result is far from trivial. The right side of Fig. 1 , which plots the axial cross section of the optimal design, shows that the profile of the cooling channels changes in two dimensions: axially with the height of the core and radially across the different assembly rings. The shape of the cooling channels is also unique for each of the radial assembly rings rather than being a scaled or translated version of each other. The top plot in Fig. 5 also shows a significant reduction in the fuel volume needed to maintain the reactor critical at a fixed power level compared with the traditional, uniform design. Lastly, the extension of this result is that the reactor can be operated at higher power levels for the same amount of fuel and peak fuel temperature limits.

Summary of accomplishments

This paper presents the results for the AI-based design optimization of a full nuclear reactor core with arbitrary geometry cooling channels. To accelerate the optimization space search, the authors developed a ML-based multiphysics emulator capable of running efficiently on Summit. The authors demonstrated how an AI-based optimization algorithm can efficiently sample the vast and continuous search space of arbitrary geometry to find the optimal solution with significant performance improvement. In the established challenge problem, the authors demonstrated a 3× improvement in the performance metric of reducing temperature peaking factors across the core in the radial and axial directions.

Future for nuclear design with arbitrary geometry

The authors envision a rapidly developing and promising future for nuclear systems design with arbitrary geometry. Arbitrary geometry enabled through advanced manufacturing provides a vast variety of unexplored opportunities in nuclear systems design. Historically, many engineering objectives in nuclear reactor design were met through creative combinatorial solutions of fuel loading axially and radially. Arbitrary geometry allows researchers to explore alternative solutions to these engineering challenges. Furthermore, combining variable fuel loading with elements of arbitrary geometry to maximize nuclear reactor safety and economics is an exciting opportunity.

Future for ML-based surrogate models for rapid design evolution

The second exciting opportunity that could result from this work is the rapid design evolution that can be achieved with ML-based surrogate models, as presented in this work. The authors demonstrated that it is possible to construct ML-based surrogate models capable of capturing a large percentage of the system physics but that can be evaluated to predict the performance of candidate designs at a fraction of the computational time. This step is absolutely necessary to progress to searching larger and larger design spaces that allow for more complex nuclear system geometries.

Future for AI-based nuclear design

The authors do not anticipate that the AI-based nuclear systems design will completely replace human designers but rather anticipate that AI-based design will become one of the main tools of the human designer. In this case, the way in which engineers think about the design problem must shift. The new focus must be to carefully craft the parameters of the optimization problem and establish the objective and constraints. The accurate formulation of the objectives will be vital, especially finding the right balance between multiple objectives. The parameters of the optimization must be chosen very carefully to reduce the possible design space as much as possible while maintaining enough flexibility to allow for significant performance improvements.

Although many challenges undoubtedly still remain, the combination of (1) arbitrary geometry enabled by advanced manufacturing, (2) ML-based surrogate models for fast and predictive computational evaluation, and (3) AI-based optimization algorithms form a very exciting future for nuclear design with the potential to discover revolutionary changes in the safety, efficiency, and economy of nuclear systems helping contribute to safer and cleaner energy for the world.

Oak Ridge National Laboratory. Transformational challenge reactor program. https://tcr.ornl.gov/ (2021). Accessed 17 August 2021.

Sobes, V., et al . Artificial intelligence design of nuclear systems empowered by advanced manufacturing. In PHYSOR 2020—Transition to a Scalable Nuclear Future , Cambridge, United Kingdom, March 29–April 2, 2020.

B. R. Betzler, B. J. Ade, et al . Advanced manufacturing for nuclear core design. In PHYSOR 2020—Transition to a Scalable Nuclear Future , Cambridge, United Kingdom, March 29–April 2, 2020.

Oak Ridge Leadership Computing Facility, “Summit: America’s Newest and Smartest Supercomputer,”. https://www.olcf.ornl.gov/Summit/ (2021). Accessed 17 August 2021.

Betzler, B. R. et al. Advanced Manufacturing for Nuclear Core Design (Oak Ridge National Laboratory, 2019).

Book Google Scholar

Wilding, P. R., Murray, N. R. & Memmott, M. J. The use of multi-objective optimization to improve the design process of nuclear power plant systems. Ann. Nucl. Energy 137 , 107079. https://doi.org/10.1016/j.anucene.2019.107079 (2020).

Article CAS Google Scholar

Pereira, C. M. N. A. & Lapa, C. M. F. Coarse-grained parallel genetic algorithm applied to a nuclear reactor core design optimization problem. Ann. Nucl. Energy 30 (5), 555–565. https://doi.org/10.1016/S0306-4549(02)00106-8 (2003).

Pereira, C. M. N. A., Schirru, R. & Martinez, A. S. Basic investigations related to genetic algorithms in core designs. Ann. Nucl. Energy 26 (3), 173–193. https://doi.org/10.1016/S0306-4549(98)00036-X (1999).

Jayalal, M. L., Ramachandran, S., Rathakrishnan, S., Satya Murty, S. A. V. & Sai Baba, M. Application of genetic algorithm methodologies in fuel bundle burnup optimization of pressurized heavy water reactor. Nucl. Eng. Design 281 , 58–71. https://doi.org/10.1016/S0306-4549(98)00036-X (2015).

Pazirandeh, A. & Tayefi, S. Optimizing the fuel management in a VVER-1000 reactor using an artificial neural network. Ann. Nucl. Energy 42 , 112–118. https://doi.org/10.1016/S0306-4549(98)00036-X (2012).

Zameer, A., Mirza, S. M. & Mirza, N. M. Core loading pattern optimization of a typical two-loop 300MWe PWR using simulated annealing (SA), novel crossover genetic algorithms (GA) and hybrid GA(SA) schemes. Ann. Nucl. Energy 65 , 122–131. https://doi.org/10.1016/j.anucene.2013.10.024 (2014).

Gomez-Fernandez, M. et al. Status of research and development of learning-based approaches in nuclear science and engineering: A review. Nucl. Eng. Des. 359 , 110479. https://doi.org/10.1016/j.nucengdes.2019.110479 (2020).

Liu, Z., Wang, J., Tan, S., Qiao, S. & Ding, H. Multi-objective optimal design of the nuclear reactor pressurizer. Int. J. Adv. Nucl. Reactor Design Technol. 1 , 1–9. https://doi.org/10.1016/j.jandt.2019.09.001 (2019).

Article Google Scholar

Betzler, B. R., Chandler, D., Cook, D. H., Davidson, E. E. & Ilas, G. Design optimization methods for high-performance research reactor core design. Nucl. Eng. Des. 352 , 110167. https://doi.org/10.1016/j.nucengdes.2019.110167 (2019).

J. Pevey, O. Chvala, S. Davis, V. Sobes, W.Hines Genetic algorithm design of a coupled fast and thermal subcritical assembly. Nucl. Technol. 206 (4) (2020).

A. Archibald, V. Sobes, B. Hiscox, E. Popov, et al . Physics based machine learning for HPC computational design. In Conference on Data Analysis 2020 , Santa Fe, New Mexico, February 26, 2020.

Forrester, A., Sobester, A. & Keane, A. Engineering Design Via Surrogate Modelling: A Practical Guide (Wiley, 2008).

Williams, C. K. I. & Rasmussen, C. E. Gaussian Processes for Machine Learning Vol. 2 (MIT Press, 2006).

MATH Google Scholar

MCNP—A General Monte Carlo N-Particle Transport Code, Version 5 , Los Alamos National Laboratory, Vol. I, 2–71 ( 2–80 ) (2005).

Siemens. Simcenter STAR-CCM+ software. https://www.plm.automation.siemens.com/global/en/products/simcenter/STAR-CCM.html .

ANSYS, Inc. ANSYS-12.0 Theory Guide (2009).

Download references

Acknowledgements

This manuscript has been authored by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the US Department of Energy (DOE). The US government retains and the publisher, by accepting the article for publication, acknowledges that the US government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for US government purposes. DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan ( http://energy.gov/downloads/doe-public-access-plan ). This work was funded by the U.S. Department of Energy Office of Nuclear Energy Transformational Challenge Reactor program. This research used resources of the Oak Ridge Leadership Computing Facility at the Oak Ridge National Laboratory, which is supported by the Office of Science of the U.S. Department of Energy under Contract No. DE-AC05-00OR22725.

Author information

Authors and affiliations.

University of Tennessee, Knoxville, USA

Vladimir Sobes

Oak Ridge National Laboratory, Oak Ridge, USA

Briana Hiscox, Emilian Popov, Rick Archibald, Cory Hauck & Ben Betzler

Ultra Safe Nuclear Corporation, Oak Ridge, USA

Kurt Terrani

You can also search for this author in PubMed Google Scholar

Contributions

V.S.: conceptualization; formal analysis; investigation; methodology; project administration; supervision; visualization; writing—original draft; writing—review and editing. B.H., E.P.: conceptualization; data curation; formal analysis; investigation; methodology; software; validation; visualization; writing—original draft; writing—review and editing. R.A.: conceptualization; data curation; formal analysis; investigation; methodology; resources; software; validation; visualization; writing—original draft; writing—review and editing. C.H.: conceptualization; formal analysis; investigation; methodology; visualization. B.B., K.T.: conceptualization; funding acquisition; project administration; resources; supervision; writing—review and editing.

Corresponding author

Correspondence to Vladimir Sobes .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Supplementary information., rights and permissions.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Sobes, V., Hiscox, B., Popov, E. et al. AI-based design of a nuclear reactor core. Sci Rep 11 , 19646 (2021). https://doi.org/10.1038/s41598-021-98037-1

Download citation

Received : 07 April 2021

Accepted : 02 September 2021

Published : 04 October 2021

DOI : https://doi.org/10.1038/s41598-021-98037-1

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

Dynamic recrystallization behavior and strengthening mechanism of a novel mo–ti3alc2 alloy at ultrahigh temperature.

- Xin-Yuan Zheng

- Shi-Zhong Wei

Rare Metals (2024)

By submitting a comment you agree to abide by our Terms and Community Guidelines . If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing: AI and Robotics newsletter — what matters in AI and robotics research, free to your inbox weekly.

Laying the Foundation for New and Advanced Nuclear Reactors in the United States

NATIONAL ACADEMIES OF SCIENCES, ENGINEERING, AND MEDICINE NATIONAL ACADEMY OF ENGINEERING

The world confronts an existential challenge in responding to climate change, resulting in an urgent need to reduce greenhouse gas emissions from all sectors of the economy.

What will it take for new and advanced nuclear reactors to play a role in decarbonization? Nuclear power provides a significant portion of the world’s low-carbon electricity, and advanced nuclear technologies have the potential to be smaller, safer, less expensive to build, and better integrated with the modern grid. However, if the United States wants advanced nuclear reactors to play a role in its plans for decarbonization, there are many key challenges that must be overcome at the technical, economic, societal, and regulatory levels.

A new National Academies’ report, Laying the Foundation for New and Advanced Nuclear Reactors in the United States , discusses how the United States could support the successful commercialization of advanced nuclear reactors with near-term actions to establish policies and practices.

Nuclear Power and the Changing Energy Landscape

The U.S. electric power system is undergoing a sweeping transition as the nation moves to reduce emissions and prevent the worst effects of climate change. Plans for decarbonization rely heavily on powering as many industries as possible with low-carbon energy, from transportation to manufacturing. Meeting the growing demand for low-carbon electricity in the future will be a key challenge to overcome for the United States and the world.

If the United States wants nuclear power as part of its future low-carbon energy landscape, it will be important to provide support for the demonstration, commercialization, and deployment of new and advanced nuclear reactors.

18.2% U.S. ELECTRICITY

Nuclear power plants provide half of all low-carbon electricity in the United States. They supply 18.2% of the nation’s total electricity.

92 POWER PLANTS

There are 92 nuclear power plants in operation in the United States (with 442 across the globe).

The initial licensing lifetime of a nuclear power plant in the United States is 40 years.

Demand for low-carbon electricity is projected to grow significantly.

Despite uncertainty about the level of future demand, there are likely to be many opportunities for low-carbon energy technologies such as advanced nuclear.

Projected future electricity demand across key sectors. Three different studies show low, medium, and high growth in demand. Source: NREL 2022

What are advanced nuclear reactors and how can they be used?

Light water reactors (LWRs) are the only type of reactor currently in use at commercial nuclear power plants in the United States. However, many companies are working to develop new small modular LWR designs as well as advanced reactor concepts that are fundamentally different from the LWR design. These new and advanced nuclear reactors could potentially meet a much wider variety of energy needs than the light water reactors in service today. These applications could include:

- GENERATING ELECTRICITY FOR THE GRID

- PROVIDING HEAT

- PROVIDING PORTABLE POWER

GENERATING ELECTRICITY FOR THE GRID The main use for advanced nuclear reactors moving forward is likely to be as small modular reactors producing electricity for the grid . Some smaller reactors could be manufactured in a controlled factory setting to reduce on-site construction costs. These new power plants could potentially repurpose fossil fuel plants and take advantage of existing infrastructure.

Advanced nuclear reactors could provide heat for:

- Thermal energy storage for electricity production

- High-temperature heat for industry , such as chemical processing or hydrogen production

- Low-temperature heat for district heating, desalination, or agriculture

Advanced nuclear reactors could provide portable power for:

- Microreactors (1-10 MWe) for remote sites or transportable microreactors to meet emergency needs

- Marine propulsion

- Remote military bases

How could advanced nuclear reactors fit into decarbonization moving forward?

The race against climate change is both a marathon and a sprint. Growth in electricity demand and the need to achieve economy-wide decarbonization over the coming several decades present important long-term opportunities for advanced nuclear technologies.

The earliest demonstrations of advanced nuclear reactors are likely to be complete in the 2030s, but the timing of widescale deployment depends on many issues, especially market competitiveness.

Timeline for potential technology demonstrations and commercialization of some advanced nuclear reactors alongside broader decarbonization efforts.

- Recommendations

Developing advanced reactors on a timeframe to significantly contribute to a decarbonized energy system will require sustained effort and robust financial support in this decade and beyond by the U.S. government, the nuclear industry, and the financial community. The successful commercialization of advanced reactors will require:

For the complete list of findings and recommendations, see Appendix I of the report.

Closing Technology Research Gaps

Advanced nuclear reactor technologies hold the promise for safer, more efficient, and more nimble designs than currently deployed nuclear technologies. However, the various advanced reactors under development are at different levels of technological maturity. These projects must resolve technology gaps and demonstrate new business use cases before wide-scale deployment.

While many of the current concepts plan to move towards commercial reactor demonstration with existing materials, focused investment to create better-performing materials (particularly for reactor core materials and cladding) could lead to significant improvements in safety, reliability, and affordability.

RECOMMENDATION 2.2: The Department of Energy’s Office of Nuclear Energy should initiate a research program that sets aggressive goals for improving materials performance. This could take the form of a strategic partnership for research and development involving NRC, EPRI, the nuclear industry, national labs, and universities. The program should incentivize the use of modern materials science to decrease the time to deployment of materials with improved performance and to accelerate the qualification (ASME Section III, Division 5 or equivalent) and understanding of life-limiting degradation processes of a limited number of high performance structural materials, e.g., reactor core materials and cladding. Learn more in Chapter 2 .

In addition to providing electricity to customers across economic sectors, nuclear power plants can provide heat for industrial processes. The heat generated could be used for desalination, district heating, or producing hydrogen or synthetic fuels. All of these applications could become important as the chemical, materials, and transportation sectors transition to low-carbon operations.

RECOMMENDATION 5.1: Industrial applications using thermal energy present an important new mission for advanced reactors. Key research and development needs for industrial applications include assessing system integration, operations, safety, community acceptance, market size as a function of varying levels of implicit or explicit carbon price, and regulatory risks, with hydrogen production as a top priority. The Department of Energy, with the support of industry support groups such as the Electric Power Research Institute and the nuclear vendors, should conduct a systematic analysis of system integration, operation, and safety risks to provide investors with realistic models of deployment to inform business cases and work with potential host communities. Learn more in Chapter 5 .

Structured Federal Funding from Design to Deployment

In order to ensure the efficient deployment of scarce resources, U.S. federal government programs for advanced nuclear development need better coordination and continuity from early research and development through demonstration and deployment. Programs should include decision points for continuation or termination of funding for specific reactor concepts dependent on meeting key milestones for performance, budget, and siting.

RECOMMENDATION 4.2: The nuclear industry and the Department of Energy’s Office of Nuclear Energy should fully develop a structured, ongoing program to ensure the best performing technologies move rapidly to and through demonstration as measured by technical (testing, reliability), financial (cost, schedule), regulatory, and social acceptance milestones. Concepts that do not meet their milestones in the ordinary course should no longer receive support and newer concepts should be allowed to enter the program in their place.

RECOMMENDATION 4.3: Congress and the DOE should maintain the Advanced Reactor Demonstration Program concept. The DOE should develop a coordinated plan among owner/operators, industry vendors, and the DOE laboratories that supports needed development efforts. The ARDP plan needs to include long-range funding linked to staged milestones; on-going design, cost, and schedule reviews; and siting and community acceptance reviews. This plan will help DOE downselect among concepts for continued support toward demonstration. A modification in the demonstration schedule that takes a phased (vs. concurrent) approach to reactor demonstration may be required. For example, funding would be continued for the first two demonstrations under the ARDP. A second round of demonstrations of designs expected to mature from the current ARDP Risk Reduction for Future Demonstrations award recipients could be funded for demonstration under an “ARDP 2.0” starting thereafter and going into the future. Learn more in Chapter 4 .

Improved Project Management and Construction

Nuclear projects in the U.S. and Europe have not been built on budget or on schedule in recent decades. These cost overruns are due to a variety of factors, including that a typical U.S. utility company does not have adequate technical and engineering personnel to plan and manage a nuclear construction project. Expertise and resources for project management are needed to support and streamline power plant construction.

Much of the cost growth does not necessarily arise from the nuclear island , but from the civil works (e.g., concrete or steel structures and the rest of the power plant).

RECOMMENDATION 6.9: While it is vital to demonstrate that advanced reactors are viable from a technical perspective, it is perhaps even more vital to ensure that the overall plant, including the on-site civil work, can be built within cost and schedule constraints. Since it is likely that costs for onsite development will still be a significant contributor to capital cost, and the ~$35M in DOE funding for advanced construction technologies R&D is small in comparison to the hundreds of millions spent on nuclear island technology research, more should be done over an extended period to research technologies that may streamline and reduce costs for this work. Learn more in Chapter 6

Some advanced reactor vendors are considering moving from the traditional “project-based” approach to a “product-based” approach in which the reactor is produced in a factory or shipyard, with the goal of improving schedules and quality while reducing costs and construction risks. However, even if this method improves the construction of nuclear components, extensive on-site construction work will still remain for the civil works.

RECOMMENDATION 6.2: Nuclear owner/operators pursuing new nuclear construction should consider establishing a consortium or joint venture to pursue the construction on behalf of the group, thereby enabling the creation and maintenance of the necessary skilled personnel to pursue projects successfully. Alternatively, advanced reactor developers operating within the traditional project delivery model should implement a long-term business relationship, preferably an equity partnership such as a joint venture or a consortium, with a qualified engineering, procurement, and construction (EPC) firm experienced in the nuclear industry. Learn more in Chapter 6 .

Strengthening the Skilled Workforce

Nuclear energy technologies require a highly skilled workforce, and the process to support and sustain these technologies over their 60+ year service life is complex and expensive. In addition to the staff needed to develop and build the next-generation of nuclear power plants, there must also be a training pipeline for staff to service the plants over many decades; technical experts to manage the fuel cycle; and regulatory, legal, and policy experts to handle licensing and oversight.

RECOMMENDATION 6.1: In anticipation of the necessary expansion in workforce to support more widespread deployment of nuclear technologies, the Department of Energy should form a cross-department (whole of government) partnership to address workforce needs that is comparable to initiatives like the multi-agency National Network for Manufacturing Innovation. The program would include the Departments of Labor, Education, Commerce, and State, and would team with labor organizations, industry, regulatory agencies, and other support organizations to identify gaps in critical skills and then fund training and development solutions that will close these gaps in time to support more rapid deployment. Learn more in Chapter 6 .

Timely Updates to Regulations

Domestic power reactors are tightly regulated by the U.S. Nuclear Regulatory Commission (NRC) in all phases of their lifecycle, including design, construction, operations, and decommissioning. The NRC is tasked with protecting public health, safety, and the environment by adjusting regulatory requirements and verifying safety claims for new reactor technologies and applications. Advanced nuclear reactors present new use cases and regulatory challenges. Work to develop new regulatory frameworks should begin now to support future deployment of advanced nuclear reactors.

While the NRC must maintain its overriding commitment to safety, the regulatory process should be made as efficient as possible if advanced reactors are to be commercialized in the coming decades.

RECOMMENDATION 7.1: Advanced reactors will not be commercialized if the regulatory requirements are not adjusted to accommodate their many differences from existing light water reactors. A clear definition of the regulatory requirements for a new technology must be established promptly if timely deployment is to be achieved. The NRC needs to enhance its capability to resolve the many issues with which it is and will be confronted. In recognition of the urgency for the NRC to prepare now, Congress should provide increased resources on the order of 10s of millions of dollars per year to the NRC that are not drawn from fees paid by existing licensees and applicants. Learn more in Chapter 7

Some reactor vendors anticipate opportunities to deploy their reactors near or in urban environments or in the vicinity of industrial facilities that will use heat produced by the reactor. These applications of advanced reactors will present unique siting and emergency planning issues. Careful and early examination of such issues is necessary to define the future range of economic opportunities that are available for advanced reactors.

RECOMMENDATION 7.4: The NRC should expedite the requirements and guidance governing siting and emergency planning zones (EPZs) in order to enable vendors to determine the restrictions that will govern the deployment of their reactors. Learn more in Chapter 7 .

Community Engagement and Societal Acceptance

Societal acceptance is necessary if new reactors are to play an expanded role in a decarbonized energy system, and it should be considered early in the design and verification process. The industry should engage with communities affected by prospective new construction, hear their needs and concerns, and adjust plans as a result. The effort should reflect an overriding commitment to honesty, early engagement through credible information channels, and genuine effort to develop a partnership.

Sociological approaches must become part of the nuclear energy research and development cycle, treated with the same seriousness as technology development. New risk communication strategies—grounded in rigorous social science (rather than polling) and respect for community apprehensions and desires—could greatly improve the prospects for nuclear deployment in the coming decades.

RECOMMENDATION 8.4: The developers and future owners that represent the advanced nuclear industry must adopt a consent-based approach to designing, siting, and operating new facilities. The siting approach will have to be adjusted for a particular place, time, and culture. The nuclear industry should follow the best practices, including:

Following these practices will require additional time and financial resources to be allotted to successfully site and construct new nuclear power facilities, and the industry must account for these costs in their plans. The industry should be willing to fully engage with a community, hear their concerns and needs and be ready to address them, including adjusting plans. The industry, guided by experts in consent-based processes, should capture best siting practices in guidance documents or standards. The study held an information gathering workshop on understanding societal challenges facing nuclear power in September 2021. Watch videos from the talks and explore the topics discussed on the workshop resource page . Learn more in Chapter 8 .

Advancing Security and Safeguards

Advanced reactor designs and deployment scenarios are far different from conventional nuclear power reactors, with a different set of security concerns. New security considerations for advanced nuclear reactor designs include:

The Nuclear Regulatory Commission (NRC) has proposed significant modifications to physical security requirements to accommodate designs and operations proposed by licensees of advanced reactors. There are many hurdles remaining. Clear NRC guidance is needed, as well as a fuller understanding of the vulnerabilities that the new designs and deployment scenarios may present.

RECOMMENDATION 9.1: The modification of the security requirements proposed by the NRC staff could have significant implications for the design, staffing and operations of advanced reactors, thereby impacting business plans. Delays in providing clear regulatory guidance may impact capital availability and increases the potential for costly re-design if guidelines do not align with expected modifications to existing protocols. Congress should provide additional funding for NRC evaluation of security guidelines and the Commission should expedite its consideration of the staff proposal and seek to complete the rulemaking promptly if significant changes are deemed appropriate. In that case, the prompt completion of the associated guidance should also be a high priority. Learn more in Chapter 9

As advanced reactors continue to be developed with the potential of rapid scale-up both domestically and internationally in the coming decades, it is crucial to recognize, prioritize, and address gaps in safeguards technology and to incorporate key measurement capabilities at the earliest stages of the design process. The U.S. government has established a robust set of programs and organizations that will support advanced reactor developers across the spectrum of research, development, and deployment, including support for domestic and international safeguards and security research, international engagement, and licensing assessment.

RECOMMENDATION 9.4: The United States should increase sustained long-term financial and technical support for bilateral and multilateral programs (e.g., IAEA) to build capacity in likely partner countries to deploy new and advanced reactors that meet safety, security and safeguards requirements, including support from U.S. national labs and universities as training platforms. It should seek commitments from vendors, supplier countries, and customer countries to adhere to the highest standards of safety, safeguards, and security. The Departments of Energy and State should partner with U.S. reactor vendors to develop a safety, safeguards and security “package,” where the United States and the vendor could offer customized support to a host country for developing and implementing new safety, security and safeguards arrangements. Learn more in Chapter 9 .

Developing Competitive Financing Options

The upfront financing costs for developing nuclear reactors are currently higher than those for other energy technologies because of large capital requirements, extended development timelines, and limited financing options. Incentives to support commercialization and more flexible financing options would help support new reactor deployment.

The commercial deployment of low-carbon energy resources will require substantial investment. In order to obtain funds at this scale, the investments must present sufficiently low risk that they can compete with other “ordinary” investments in the public equity and debt markets. Widespread commercial deployment of nuclear reactors will occur only if the projects can convincingly demonstrate that they can compete in a marketplace with alternatives.

RECOMMENDATION 4.4: To enable a cost-competitive market environment for nuclear energy, federal and state governments should provide appropriately tailored financial incentives (extending and perhaps enhancing those provided recently in the Inflation Reduction Act) that industry can use as part of a commercialization plan, consistent with the successful approaches used with renewables. These tools may vary by state, locality, and market type. Continued evaluation of the recently passed incentives will need assessment to determine their adequacy. The scale of these incentives needs to be sufficient not only to encourage nuclear vendors, but also the supporting supply chains. Learn more in Chapter 4

Many new and advanced nuclear vendors in the United States anticipate a strong international market for their designs. However, non-U.S. vendors have more options for financing the export and deployment of advanced reactors than U.S. vendors, which will reduce the competitiveness of U.S. companies and limit opportunities for the United States to promote global nuclear safety and security.

RECOMMENDATION 10.2: International nuclear projects by U.S. exporters are likely to require a financing package that reflects a blending of federal grants, loans, and loan guarantees along with various forms of private equity and debt financing. The Executive Branch should work with the private sector to build an effective and competitive financing package for U.S. exporters. Learn more in Chapter 10 .

Committee Members

Richard A. Meserve, Chair

Ahmed Abdulla

Jaquelin Cochran

Michael L. Corradini

Richard Cupitt

Leslie Dewan

Michael Ford

Kirsty Gogan

Allison M. Macfarlane

David K. Owens

James Rispoli

Sola Talabi

Steven J. Zinkle

Dr. Ahmed Abdulla is an assistant professor in the Department of Mechanical and Aerospace Engineering at Carleton University (Ottawa, ON). He develops energy system models for deep decarbonization. Modeling efforts focus on evaluating the role of disruptive energy technologies that sit at a low level of technical readiness; including energy storage systems, advanced nuclear power, and negative emissions technologies. Dr. Abdulla advances process modeling, systems engineering, engineering economics, and quantitative risk and decision analysis in his research. He integrates insights from public policy and behavioral science in his models, to deploy truly sustainable technologies—ones that are both techno-economically viable and socio-politically acceptable. Dr. Abdulla co-leads the APEX (Alternative Pathways for the Energy Transition) research group at Carleton, which consists of highly interdisciplinary engineers devoted to accelerating the transition to a deeply decarbonized energy system and averting the worst consequences of climate change. Results from his research have been published in leading journals, including Nature Climate Change, Nature Communications, the Proceedings of the National Academy of Sciences, Philosophical Transactions of the Royal Society; Environmental Science and Technology; Risk Analysis; and Environmental Research Letters. His findings have been featured in The Wall Street Journal, The Los Angeles Times, Bloomberg News, and National Public Radio. He received his B.S.E. in Chemical Engineering from Princeton University, and his Ph.D. in Engineering and Public Policy from Carnegie Mellon University.

Dr. Todd Allen is currently a faculty member and chair of the Nuclear Engineering & Radiological Sciences Department at the University of Michigan and a senior fellow at Third Way, a DC-based think tank, supporting their clean energy portfolio. He was the Deputy Director for Science and Technology at the Idaho National Laboratory from January 2013 through January 2016. Both the INL and Third Way positions occurred while on leave from the University of Wisconsin. Previously, he was a professor in the Engineering Physics Department at the University of Wisconsin, a position held from September 2003 through December 2018. In addition to his teaching and research responsibilities at Wisconsin, he was also the Scientific Director of the Advanced Test Reactor National Scientific User Facility, centered in Idaho Falls, Idaho, at the Idaho National Laboratory. He held that position from March 2008-December 2012. He was also the Director of the Center for Material Science of Nuclear Fuel, a Department of Energy-sponsored Energy Frontier Research Center. Prior to joining the faculty at the University of Wisconsin, he was a Nuclear Engineer at Argonne National Laboratory-West in Idaho Falls. His doctoral degree is in Nuclear Engineering from the University of Michigan (1997). Prior to graduate work, he was an officer in the United States Navy Nuclear Power Program.

Dr. Jaquelin Cochran is the director of the Grid Planning and Analysis Center at the National Renewable Energy Laboratory, where she has worked since 2009. Dr. Cochran’s work has focused on the evolution of the power grid with high deployment of renewable energy. She recently led the Los Angeles 100% Renewable Energy Study and a portfolio of analyses about India’s power system. Before joining NREL, Dr. Cochran was an Assistant Professor of Natural Resource Management with KIMEP University in Almaty, Kazakhstan. She also served as a Peace Corps Volunteer for two years with the Polish Foundation for Energy Efficiency (FEWE) in Krakow. She holds a Ph.D. and M.A. from the Energy & Resources Group at the University of California at Berkeley, and a B.A. from Pomona College.

Dr. Michael L. Corradini (NAE) is Emeritus Wisconsin Distinguished Professor of Nuclear Engineering and Engineering Physics at the University of Wisconsin-Madison. He served from 1995 to 2001 as Associate Dean for the College of Engineering and as Chair of Engineering Physics from 2001-2011. He has published widely in areas related to vapor explosion phenomena, jet spray dynamics, and transport phenomena in multiphase systems. From 1978-1981 he served as a member of technical staff of Sandia National Laboratories. In 1998, he was elected to the National Academy of Engineering. He has also served as a presidential appointee in 2002 and 2003 as the chairman of the Nuclear Waste Technical Review Board (a separate government agency). From 2004-2008, he served as a board member of the INPO National Accreditation Board for Nuclear Training. In 2006, he was appointed to the NRC Advisory Committee on Reactor Safeguards and was elected to the National Council on Radiation Protection. In 2010, he was appointed Chair of the Scientific Advisory Committee to the French Atomic Energy Agency. He began and served as the Director of the Wisconsin Energy Institute. He was elected as the President of the American Nuclear Society for 2012 – 2013. Michael received his B.S. in Mechanical Engineering from Marquette University, Milwaukee WI; M.S. in Nuclear Engineering from Massachusetts Institute of Technology, and Ph.D. in Nuclear Engineering from Massachusetts Institute of Technology.

Dr. Richard Cupitt is a senior fellow and director of the Partnerships in Proliferation Prevention program at Stimson. His areas of expertise include WMD nonproliferation, export controls, and foreign policy. Prior to joining Stimson, he served as the Special Coordinator for U.N. Security Council resolution 1540 in the Office of Counterproliferation Initiatives at the U.S. State Department from 2012 through 2016. As such, he led U.S. government efforts to further implementation of the more than two hundred legally binding obligations and recommendations of the resolution, which aims to combat proliferation of WMD and their means of delivery, especially to non-state actors such as terrorists and criminal organizations. From 2005 to 2012, he worked as an expert for the committee established pursuant to U.N. Security Council resolution 1540 (2004), a subsidiary body of the U.N. Security Council, monitoring and facilitating implementation of the resolution in all U.N. Member States, along with building relationships with more than forty international organizations, coordinating assistance activities, and conducting outreach with industry and academia. Elected coordinator of the experts from 2010-2012, he also led the work in several specialized areas including combating the financing of proliferation and export controls. From 2004 to 2008, Cupitt also held a position as Scholar-in-Residence at American University and worked as Special Adviser for International Cooperation for the U.S. Undersecretary of Commerce in the Bureau of Industry and Security from 2002-2004. From 1988 to 2002, Cupitt had various posts for the Center International Trade and Security (CITS) of the University of Georgia, including Associate Director, as well as acting as a visiting scholar at the Center for Strategic and International Studies (CSIS) in 2000-2002. Cupitt also has held academic positions at Emory University and the University of North Texas. He has produced four books and more than 20 peer-reviewed articles on nonproliferation export controls, along with dozens of other security or trade-oriented publications. In addition, he has served as a consultant on projects for the U.S. State Department, several U.S. national commissions, U.S. national nuclear laboratories, and various international organizations.

Dr. Leslie Dewan is the CEO of RadiantNano, a nuclear startup developing next-generation radiation detectors with applications in national security, clean energy production, and medical diagnostics. Previously, she was the CEO of Transatomic Power, a company that designed safer nuclear reactors that leave behind less waste than conventional designs. Leslie received her Ph.D. in nuclear engineering from MIT, with a research focus on computational nuclear materials. She also holds S.B. degrees from MIT in mechanical engineering and nuclear engineering. Before starting her Ph.D., she worked for a robotics company in Cambridge, MA, where she designed search-and-rescue robots and equipment for in-field identification of chemical and nuclear weapons. Leslie has been awarded an MIT Presidential Fellowship and a Department of Energy Computational Science Graduate Fellowship. She has served on the MIT Corporation, MIT’s board of trustees. Leslie has been named a TIME Magazine "30 People Under 30 Changing the World," an MIT Technology Review "Innovator Under 35," a Forbes "30 Under 30,” a National Geographic Explorer, and a World Economic Forum Young Global Leader.

Dr. Michael Ford is the Associate Laboratory Director for Engineering at the Princeton Plasma Physics Laboratory. In this role, Dr. Ford leads the pursuit of PPPL’s mission to develop advanced fusion engineering knowledge and techniques and is responsible for all engineering support throughout the Laboratory. Prior to assuming his position at PPPL, Dr. Ford served as the Strategy Development Director for the Energy and Global Security (EGS) Directorate at the Argonne National Laboratory. At Argonne, he helped develop strategies designed to build increased sponsor support for energy and national security-related research. Dr. Ford remains active in energy, engineering risk, and environmental policy research, and led Phase I of the National Demonstration Reactor Siting Study supporting the National Reactor Innovation Center. Prior to his work in the National Laboratories system, Dr. Ford held research positions at the Harvard University Center for the Environment and at the Belfer Center for Science and International Affairs, Harvard Kennedy School. He earned his PhD in engineering and public policy at Carnegie Mellon University (CMU), where he conducted research in energy and the environment, with a focus on advanced reactor technology development and proliferation risk. Dr. Ford also served a full career as an officer in the United States Navy and held Navy subspecialties in nuclear engineering, resource management, and operations analysis. During his time on active duty, CAPT (Ret) Ford commanded the guided-missile cruiser USS BUNKER HILL (CG 52) and the guided-missile destroyer USS MUSTIN (DDG 89) and served as lead nuclear engineer (Reactor Officer) aboard USS NIMITZ (CVN 68). Ashore, he held senior finance and resource management positions on the U.S. Navy and U.S Joint Staffs at the Pentagon. In these positions, he developed standards for new warfare systems development and helped lead the Navy Quadrennial Defense Review process.

Kirsty Gogan is an internationally sought-after advisor to governments, industry, academic networks and NGOs. Kirsty is regularly invited as an expert speaker on science communication, climate change, competitiveness and innovation to high profile events around the world. She has more than 15 years of experience as a senior advisor to Government on climate and energy policy, including 10 Downing Street, and the Office of the Deputy Prime Minister. As Deputy Head of Civil Nuclear Security, Kirsty reviewed the UK national communications response to Fukushima, and implemented a number of recommendations supported by industry and Government. She subsequently provided editorial oversight for the revision of the Civil Nuclear Emergency Planning and Response Guidance. Leading the Government’s public consultation into the UK’s nuclear new build program, Kirsty addressed public concerns about nuclear power and engaged antinuclear campaigners in a constructive dialogue process with Government that continues to this day. Kirsty is now managing partner of LucidCatalyst, a highly specialized international consultancy offering thought leadership, strategy development and techno-economic expertise focused on multiplying and accelerating zero carbon technology options available for large-scale, affordable, market-based decarbonization of the global economy over a wide range of future scenarios. Kirsty is also co-founder of Energy for Humanity (EFH), an environmental NGO focused on large scale deep decarbonization and energy access. Under Kirsty’s leadership, EFH was shortlisted for the Business Green Leaders “Green NGO of the Year” Award in 2016 and received the U.S. Nuclear Industry Council Trailblazer Award in 2019. At COP21 in Paris, EFH organized a press conference that led to media coverage reaching an estimated audience of 800 million people globally. EFH jointly launched the Clean Energy Ministerial Flexible Nuclear Campaign in May 2019, supported by the Canadian, U.S., and UK governments, and in partnership with ClearPath Foundation. Kirsty is also co-founder, with Eric Ingersoll, of TerraPraxis, a new non-profit focused on energy innovation for a prosperous planet.