CNC Machine Shop Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Construction & Engineering

Are you about starting a CNC machine company? If YES, here is a detailed sample CNC machine shop business plan template & FREE feasibility report.

If you are looking for a profitable engineering business whose products can be used by players in the production industry, then one of your options is to open a CNC machine shop company. Starting a CNC machines shop company is relatively capital intensive because of the expensive lathe machines, milling machines, grinders, drill presses and other machines and equipment needed to run the business.

It also requires serious planning and hard work but the fact remains that it is indeed a profitable business to go into. Below is a sample CNC machine shop business plan template that will help you successfully launch your own business.

A Sample CNC Machine Shop Business Plan Template

1. industry overview.

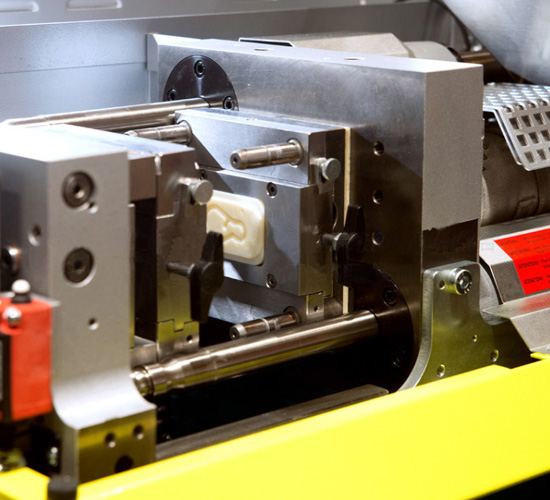

A machine shop is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plastic (but sometimes of other materials such as glass or wood).

A machine shop can be a small business (such as a job shop) or a portion of a factory, whether a toolroom or a production area for manufacturing. The parts produced can be the end product of the factory, to be sold to customers in the machine industry, the car industry, the aircraft industry, or others. In other cases, companies in those fields have their own machine shops.

CNC machine shop business is a subset of the Machine Shop Services industry and businesses in this industry cuts raw materials into specific shapes and sizes using a variety of tools such as lathes, milling machines, grinders and drill presses.

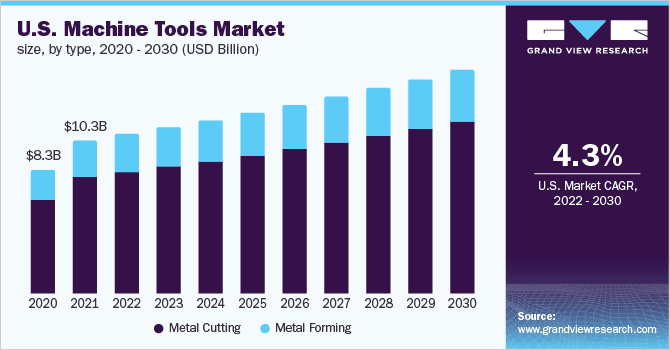

Almost all forms of metal product fabrication involve machining, and industry operators may also machine plastic and composite materials. In the U.S., the industry generates over $44 billion annually from more than 19,685 registered and licensed machine shops (CNC machine shops inclusive).

The industry is responsible for the employment of over 248,609 people. Experts project the machine shop industry to grow at a – 0.1 percent annual rate between 2014 and 2019. It is important to state that no machine shop can boast of having a lion market share of the market in the industry in the united states of America.

A recent report published by IBISWorld shows that the Machine Shop Services industry has remained largely unchanged after posting two years of revenue declines and three years of revenue increases over the five years to 2019. Revenue has decreased marginally at an annualized rate of 0.1 percent to an estimated $43.8 billion in 2019.

Although nearly all of this industry’s downstream markets have expanded over the past five years and are currently operating with improved market conditions, falling metals prices between 2013 and 2016 contributed to lower revenue in that period.

Rising metals prices after 2017 is propelling industry growth, with revenue expected to rise 0.1 percent in 2019. Technological advancement in machining is largely driven by the defense and aerospace markets. It is important to point out that a machine shop can be a capital intensive business, because the purchase of equipment can require large investments.

A machine shop can also be labor-intensive, especially if it is specialized in repairing machinery on a job production basis, but production machining (both batch production and mass production) is much more automated than it was before the development of CNC, programmable logic control (PLC), microcomputers, and robotics.

It no longer requires masses of workers, although the jobs that remain tend to require high talent and skill. Training and experience in a machine shop can both be scarce and valuable. Some of the factors that encourage aspiring entrepreneurs and investors to start a CNC machine shop is the fact that the market for its products is growing rapidly in the United States and it is not seasonal.

That makes it easier for entrepreneurs who are interested in the business to come into the industry at any time they desire; the entry barriers might be high but that any serious-minded entrepreneur can comfortably raise the startup capital even if it means collecting loans from the bank.

The machine shop services industry is a highly profitable industry and it is open for any aspiring entrepreneur to come in and establish his or her business as long as you are able to obtain the required license and permits; you can choose to start on a small scale producing and supplying at a cottage level or you can choose to start on a large scale with distribution network spread across key cities all around the United States of America.

2. Executive Summary

Jack Anderson® CNC Machine Shop, Inc. is a licensed computer numerical control (CNC) machine production company that will be involved in cutting raw materials into specific shapes and sizes using a variety of tools such as lathes, milling machines, grinders and drill presses.

We will engage in almost all forms of metal product fabrication. We have been able to lease a production facility that is a perfect fit as it relates to the production facility we want to build, and the facility is centrally located in North Platte – Nebraska. Jack Anderson® CNC Machine Shop, Inc. will produce and supply these component parts to end users at affordable prices.

There is growing interest when it comes to the production of machine component parts and new enterprises are springing up, which is why we spent time and resources to conduct our feasibility studies and market survey so as to offer much more than our competitors will be offering.

We have robust distribution network; strong online presence and our distributors are armed with the various payment options available in the United States.

Beyond the fabrication and supply of standard machine parts/components to production companies in the United States, our customer care is going to be second to none in the whole of North Platte – Nebraska and our deliveries will be timely and reliable.

We know that our customers are the reason why we are in business which is why we will go the extra mile to get them satisfied when they patronize our products. Jack Anderson® CNC Machine Shop, Inc. will ensure that all our customers are given first class treatment whenever they order machine components from us.

We have a CRM software that will enable us manage a one on one relationship with our customers no matter how large their numbers may grow to. We will ensure that we get our customers involved when making some business decisions that directly affect them.

Jack Anderson® CNC Machine Shop, Inc. will at all times demonstrate her commitment to sustainability, both individually and as a firm, by actively participating in our communities and integrating sustainable business practices wherever possible.

We will ensure that we hold ourselves accountable to the highest standards by meeting our client’s needs precisely and completely.

Jack Anderson® CNC Machine Shop, Inc. is owned by Jack Anderson. Anderson has a B.Tech. in Mechanical Production Engineering and with over 25 years of hands on experience in the mechanical engineering production industry, working for some of the leading brand in the United States.

3. Our Products and Services

Jack Anderson® CNC Machine Shop, Inc. will ensure that we go all the way to be involved in the production and distribution of quality machine components. We are in the industry to make profits and we will ensure that we do all that is permitted by the law in the United States to achieve our business aims and objectives.

In essence, we will engage in;

- Manual and computer numerical control (CNC) milling services

- Turning services to produce cylindrical components

- Drilling and boring services

- Sawing services

- Broaching services to enlarge existing holes

- Fastening services using automatic screw machines

- Grinding and planning services

4. Our Mission and Vision Statement

- Our vision is to be listed amongst the top 5 Computer Numerical Control (CNC) machine shops in the whole of the United States of America.

- Our mission is to establish a computer numerical control (CNC) machine shop that will distribute quality machine parts at affordable prices to retailers, and industries in North Platte and other cities in and around Nebraska where we intend marketing our products and services.

Our Business Structure

Our intention of starting a Computer Numerical Control (CNC) machine shop is to build a standard Computer Numerical Control (CNC) machine shop whose products will be distributed all across the United States of America and the globe.

We will ensure that we put the right structures in place that will support the kind of growth that we have in mind while setting up the business. We want to put modalities in place that will guide us in hiring people that are qualified, honest, customer centric and are ready to work to help us build a prosperous business that will benefit all the stake holders.

As a matter of fact, profit-sharing arrangement will be made available to all our senior management staff and it will be based on their performance for a period of ten years or more. In view of that, we have decided to hire qualified and competent hands to occupy the following positions that will be made available at Jack Anderson® CNC Machine Shop, Inc.;

- Chief Executive Officer (Owner)

- Production Manager

- Human Resources and Admin Manager

Machine Operators

Sales and Marketing Manager

- Accountants/Cashiers

- Customer Services Executive

- Drivers/Distributors

5. Job Roles and Responsibilities

Chief Executive Officer – CEO:

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results

- Creates, communicates, and implements the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Responsible for fixing prices and signing business deals

- Responsible for providing direction for the business

- Responsible for signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Reports to the board

Admin and HR Manager

- Responsible for overseeing the smooth running of HR and administrative tasks for the organization

- Maintains office supplies by checking stocks; placing and expediting orders; evaluating new products.

- Ensures operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Defines job positions for recruitment and managing interviewing process

- Carries out induction of new team members

- Accountable for training, evaluation and assessment of employees

- Responsible for arranging travel, meetings and appointments

- Oversees the smooth running of the daily office activities.

Production Plant Manager

- Responsible for overseeing the smooth running of the Computer Numerical Control (CNC) machine shop

- Part of the team that determines the quantity and quality of machine component parts that are to be produced

- Maps out strategies that will lead to efficiency amongst workers in the plant

- Responsible for training, evaluation and assessment of plant workers

- Ensures that the steady flow of both raw materials to the plant and easy flow of finished products through wholesale distributors to the market

- Ensures that the plant meets the expected safety and health standard at all times.

- Responsible for using space and mechanical handling equipment efficiently and making sure quality, budgetary targets and environmental objectives are met

- In charge of coordinating automated and computerized systems where necessary

- In charge of overseeing the maintenance of vehicles, machinery and equipment.

- Ensures that proper records of machine components are kept and warehouse does not run out of products

- Ensures that the production facility is in tip top shape and machine component parts products are properly arranged and easy to locate

- Controls supply inventory

- Handle manual and computer numerical control (CNC) milling services

- Handle turning services to produce cylindrical components

- In charge of drilling and boring services

- Handle sawing services

- Handle broaching services to enlarge existing holes

- Handle fastening services using automatic screw machines

- Handle grinding and planning services

- Manages external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Models demographic information and analyze the volumes of transactional data generated by customer purchases

- Identifies, prioritizes, and reaches out to new partners, and business opportunities et al

- Identifies development opportunities; follows up on development leads and contacts

- Responsible for supervising implementation, advocate for the customer’s needs, and communicate with clients

- Documents all customer contact and information

- Represents the company in strategic meetings

- Helps to increase sales and growth for the company

Accountant/Cashier:

- Responsible for preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports

- Responsible for financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting

- Responsible for developing and managing financial systems and policies

- Responsible for administering payrolls

- Ensures compliance with taxation legislation

- Handles all financial transactions for the organization

- Serves as internal auditor for the organization

Client Service Executive

- Ensures that all contacts with clients (e-mail, walk-In center, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with customers on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Manages administrative duties assigned by the human resources and admin manager in an effective and timely manner

- Consistently stays abreast of any new information on the organizations’ products, promotional campaigns etc. to ensure accurate and helpful information is supplied to customers when they make enquiries

Distribution Truck Drivers

- Assists in loading and unloading machine component parts and raw materials

- Keeps a record of vehicle inspections and make sure the truck is equipped with safety equipment

- Assists the transport and logistics manager in planning their route according to a distribution schedule.

- Local-delivery drivers may be required to sell products or services to stores and businesses on their route, obtain signatures from recipients and collect cash.

- Inspects vehicles for mechanical items and safety issues and perform preventative maintenance

- Complies with truck driving rules and regulations (size, weight, route designations, parking, break periods etc.) as well as with company policies and procedures

- Collects and verifies delivery instructions

- Reports defects, accidents or violations

6. SWOT Analysis

Our goal of starting out in North Platte and service industries only within North Platte – Nebraska is to test run the business for a period of 3 to 5 years to know if we will invest more money, expand the business and then start supplying our machine component parts all around the state of Nebraska, other cities across the United States and the world.

We are quite aware that there are several Computer Numerical Control (CNC) machine shops and contractors all over North Platte and even in the same location where we intend locating ours, which is why we are following the due process of establishing a business.

We know that if a proper SWOT analysis is conducted for our business, we will be able to position our business to maximize our strength, leverage on the opportunities that will be available to us, mitigate our risks and be equipped to confront our threats.

Jack Anderson® CNC Machine Shop, Inc. employed the services of an expert HR and Business Analyst with bias in retailing and distribution to help us conduct a thorough SWOT analysis and to help us create a Business model that will help us achieve our business goals and objectives.

This is the summary of the SWOT analysis that was conducted for Jack Anderson® CNC Machine Shop, Inc.;

Our location, the business model we will be operating on, well – equipped CNC machine shop, reliable machine component parts, varieties of payment options, quality and our excellent customer service culture will definitely count as a strong strength for Jack Anderson® CNC Machine Shop, Inc.

So, also our management team members are people who have what it takes to grow a business from startup to profitability within a record time.

A major weakness that may count against us is the fact that we are a new Computer Numerical Control (CNC) machine shop and we don’t have the financial capacity to compete with leaders in the industry especially as it relates to leveraging on economy of scales.

- Opportunities:

The industrial production index is a composite measure of output from the economy’s manufacturing, mining and utilities sectors. Higher industrial production increases demand for manufactured metal, machined products and machining services. The industrial production index is expected to increase in 2019, representing a potential opportunity for the industry.

The prime rate to our business is the interest rate charged by banks to their most creditworthy and largest corporate customers. A higher prime rate will make it more expensive for companies to fund expansionary activities. Downstream markets will experience challenges as the prime rate is expected to rise in 2019, presenting a potential threat to the industry.

7. MARKET ANALYSIS

- Market Trends

If you are a close observer of Computer Numerical Control (CNC) industry, you will agree that CNC machining is still going strong within the world of manufacturing, showing precipitous growth even amidst the slew of competing technologies and new entrants.

Even so, CNC machining is a wide ocean with many varying interests and trends within it. With so many sub-technologies, it can be hard to keep track of what the latest shifts are so here’s our handy guide for the recent developments in 2019.

A trend that emerges shows that as a result of increased adoption in india, China, Japan and other nations in the region, Asia Pacific is leading the charge. Another factor is that major manufacturers such as Okuma Corporation, Yamazaki Mazak Corporation, and DMG Mori Co., Ltd. are all based in these countries.

As a result, Asia Pacific is probably going to remain a lucrative market, and is poised to remain a leader over the next six years. A large factor that contributes to this growth is government initiatives and investment keeping the market competitive. Asia Pacific stands at USD 22.33 billion in 2018 and is expected to grow further.

So also, Europe is expected to grow as it is considered a major market for advanced technologies. Current roadblocks to beating Asia Pacific in this regard are high barriers of entry and lower investment in the market. On the other hand, the US market is currently saturated with machines.

One of the growth areas within the US has been that of the energy sector, attributing to high demands for alternative new energy sources due to fears of obsolescence of the conventional energy systems. That said, the US is definitely the highest ranking in terms of global Multi-tasking machine tools market.

Growing use of multi-tasking machines in the aerospace industry and high labor cost are the main contributors to this trend.

8. Our Target Market

The machine shop services industry has a wide range of customers; a good number of manufacturing companies, automotive companies, aerospace companies and the likes make use of machine component parts and the services offered in a machine shop.

In view of that, we have positioned our Computer Numerical Control (CNC) machine shop to service businesses in North Platte – Nebraska. We have conducted our market research and we have ideas of what our target market would be expecting from us. We are in business to retail (distribute) machine component parts to the following businesses;

- Machine production companies

- Automobile production industry

- The aircraft industry

- Production companies

- Others related production companies that make use of component fabricated parts.

Our Competitive Advantage

Jack Anderson® CNC Machine Shop, Inc. is launching a standard Computer Numerical Control (CNC) machine shop that will indeed become the preferred choice for companies that make use of fabricated machine component parts.

Our competitive advantage revolves around our ability to attract local support and patronage, easy compliance with government regulations, ability to quickly adopt new technology, ability to raise financing and our ability to follow international best practices.

Lastly, our employees will be well taken care of, and their welfare package will be among the best within our category in the industry meaning that they will be more than willing to build the business with us and help deliver our set goals and objectives.

We will also give good working conditions and commissions to freelance sales agents that we will recruit from time to time.

9. SALES AND MARKETING STRATEGY

- Sources of Income

Jack Anderson® CNC Machine Shop, Inc. is in business to attract clients to purchase our fabricated machine parts. We are in the machine shop services industry to maximize profits and we are going to ensure that we achieve our business goals and objectives.

In essence, our source of income will be;

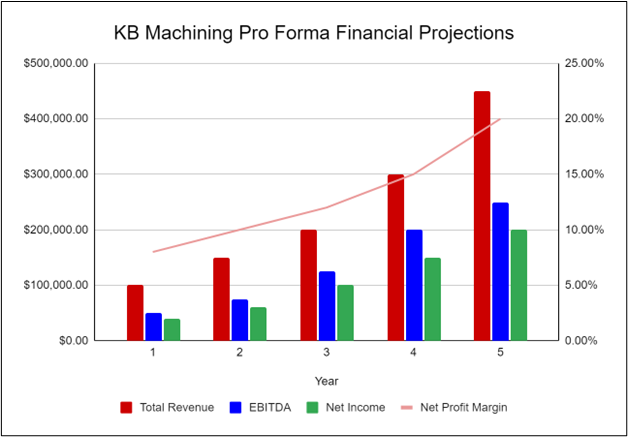

10. Sales Forecast

One thing is certain when it comes to Computer Numerical Control (CNC) machine shop, if your business is centrally positioned coupled with effective and reliable machine fabricators and good distribution network, you will always attract customers.

Jack Anderson® CNC Machine Shop, Inc. is well positioned to take on the available market in North Platte – Nebraska and we are quite optimistic that we will meet our set target of generating enough income/profits from the first six months of operation and grow the business and our clientele base.

We have been able to examine the machine shop services industry, we have analyzed our chances in the industry and we have been able to come up with the following sales forecast.

Below are the sales projections for Jack Anderson® CNC Machine Shop, Inc., it is based on the location of our business, and other factors as it relates to Computer Numerical Control (CNC) machine shop products startups in the United States;

- First Fiscal Year (FY1): $335,000

- Second Fiscal Year (FY2): $650,000

- Third Fiscal Year (FY3): $1.1 million

N.B : This projection was done based on what is obtainable in the industry and with the assumption that there won’t be any major economic meltdown and there won’t be any major competitor offering same products, distribution services and customer care services as we do within same location. Please note that the above projection might be lower and at the same time it might be higher.

- Marketing Strategy and Sales Strategy

Before choosing a location to launch Jack Anderson® CNC Machine Shop, Inc., we conducted a thorough market survey and feasibility studies in order for us to penetrate the available market and become the preferred choice in and around North Platte – Nebraska.

We hired experts who have good understanding of the Computer Numerical Control (CNC) machine shop line of business to help us develop marketing strategies that will help us achieve our business goal of winning a larger percentage of the available market in North Platte – Nebraska.

In summary, Jack Anderson® CNC Machine Shop, Inc. will adopt the following sales and marketing approach to win customers over;

- Introduce our business by sending introductory letters alongside our brochure to factories, and all the industries that make use of fabricated machine parts and key stake holders in and around North Platte – Nebraska

- Ensure that we have fabricated machine component parts/products at all times.

- Make use of attractive hand bills to create awareness business

- Position our signage/flexi banners at strategic places around North Platte – Nebraska

11. Publicity and Advertising Strategy

Even though our Computer Numerical Control (CNC) machine shop is well structured and located, we will still go ahead to intensify publicity for the business.

Jack Anderson® CNC Machine Shop, Inc. has a long-term plan of opening distribution channels all around the state of Nebraska and other cities in the United States of America which is why we will deliberately build our brand to be well accepted in North Platte before venturing out.

Here are the platforms we intend leveraging on to promote and advertise Jack Anderson® CNC Machine Shop, Inc.;

- Place adverts on community – based newspapers, radio and TV stations

- Encourage the use of word of mouth publicity from our loyal customers

- Leverage on the internet and social media platforms like; YouTube, Instagram, Facebook, Twitter, LinkedIn, Snapchat, Google+ and other platforms to promote our business.

- Ensure that our we position our banners and billboards in strategic positions all around North Platte – Nebraska

- Distribute our fliers and handbills in target areas in and around our neighborhood

- Advertise our Computer Numerical Control (CNC) machine shop in our official website and employ strategies that will help us pull traffic to the site

- Brand all our official cars and distribution trucks and ensure that all our staff wear our branded shirt or cap at regular intervals.

12. Our Pricing Strategy

Our pricing system is going to be based on what is obtainable in the Computer Numerical Control (CNC) machine shop line of business. Be that as it may, we have put plans in place to offer discounts once in a while and also to reward our loyal customers especially when they refer clients to us.

- Payment Options

The payment policy adopted by Jack Anderson® CNC Machine Shop, Inc. is all inclusive because we are quite aware that different customers prefer different payment options as it suits them but at the same time, we will ensure that we abide by the financial rules and regulation of the United States of America.

Here are the payment options that Jack Anderson® CNC Machine Shop, Inc. will make available to her clients;

- Payment via bank transfer

- Payment via credit cards

- Payment via POS machines

- Payment via online bank transfer

- Payment via check

- Payment via bank draft

In view of the above, we have chosen banking platforms that will enable our clients make payment for our fabricated machine component products purchase without any stress on their part.

13. Startup Expenditure (Budget)

From our findings, we were able to come up with the areas we will spend our resources on and this is what it would cost us to set up Jack Anderson® CNC Machine Shop, Inc. in the United States;

- The total fee for registering the business in the United States of America – $750.

- Legal expenses for obtaining licenses and permits as well as the accounting services (software, P.O.S machines and other software) – $3,300.

- Marketing promotion expenses in the amount of $3,500 and as well as flyer printing (2,000 flyers at $0.04 per copy) for the total amount of $3,580.

- The cost for hiring business consultant – $2,500.

- The cost for insurance (general liability, workers’ compensation and property casualty) coverage at a total premium – $2,400.

- The cost for payment of rent for 12 months at $1.76 per square feet tank facility cum mini depot in the total amount of $250,000.

- The total cost for production facility remodeling – $100,000.

- Other start-up expenses including stationery ($500) and phone and utility deposits ($2,500).

- Operational cost for the first 3 months (salaries of employees, payments of bills et al) – $150,000

- The cost for Start-up inventory – $300,000

- The cost for store equipment (cash register, security, ventilation, signage) – $13,750

- The cost of purchase and installation of CCTVs – $5,000

- The cost for the purchase of furniture and gadgets (Computers, Printers, Telephone, TVs, Sound System, tables and chairs et al) – $4,000.

- The cost of launching a website – $600

- Miscellaneous – $10,000

We would need an estimate of $1.2 million to successfully set up our Computer Numerical Control (CNC) machine shop in North Platte – Nebraska.

Generating Funds/Startup Capital for Jack Anderson® CNC Machine Shop, Inc.

Jack Anderson® CNC Machine Shop, Inc. is a private business that is solely owned and financed by Jack Anderson. He decided to restrict the sourcing of the startup capital to 3 major sources.

- Generate part of the startup capital from personal savings

- Source for soft loans from family members and friends

- Apply for loan from my Bank

N.B: We have been able to generate about $500,000 (Personal savings $450,000 and soft loan from family members $50,000) and we are at the final stages of obtaining a loan facility of $700,000 from our bank. All the papers and document have been signed and submitted, the loan has been approved and any moment from now our account will be credited with the amount.

14. Sustainability and Expansion Strategy

Part of the plans we have in place to sustain Jack Anderson® CNC Machine Shop, Inc. is to ensure that we continue to deliver quality products, services, improvise on how to do things faster and cheaper.

From our findings, another factor that kills new business is financial leakages. In order to plug financial leakages, the management of Jack Anderson® CNC Machine Shop, Inc. will adopt the use of payment machine and accounting software to run the business.

We are quite aware that our customers are key component to the growth and survival of our business hence we are going to continuously engage them to give us ideas on how to serve them better. We will not waste time in adopting new technology, best practices and diversifying our services once the need arises.

Our key sustainability and expansion strategy as a business is to ensure that we only hire competent and technically sound employees, create a conducive working environment and give employee benefits to all our staff. We know that if we implement our business strategies, we will grow our CNC machine shop business beyond North Platte – Nebraska to other states in the U.S in record time.

Check List/Milestone

- Business Name Availability Check: Completed

- Business Registration: Completed

- Opening of Corporate Bank Accounts: Completed

- Securing Point of Sales (POS) Machines: Completed

- Opening Mobile Money Accounts: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Leasing of production facility and construction of production plant: In Progress

- Conducting Feasibility Studies: Completed

- Generating capital from family members: Completed

- Applications for Loan from the bank : In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents and other relevant Legal Documents: In Progress

- Design of The Company’s Logo: Completed

- Printing of Promotional Materials: In Progress

- Recruitment of employees: In Progress

- Purchase of the needed machines, technology, furniture, reservoirs, computers, electronic appliances, office appliances and CCTV : In progress

- Purchase of distribution trucks: Completed

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business both online and around the community : In Progress

- Health and Safety and Fire Safety Arrangement (License): Secured

- Establishing business relationship with fabricated machine component distributors all across the United States of America: In Progress

Related Posts:

- Dump Truck Business Plan [Sample Template]

- Home Remodeling Business Plan [Sample Template]

- Building Materials Supply Business Plan [Sample Template]

- Mobile Manufactured Home Business Plan [Sample Template]

- Concrete Contracting Business Plan [Sample Template]

How To Start a CNC Business: Ultimate Guide

Written by: CNCSourced

February 20, 2024

For many, starting a CNC business is a dream job. You get to spend your days doing something you’re passionate about, with the potential to earn far more than you would in regular employment.

I know dozens of people – myself included – who have been able to turn their hobby into a thriving business, and while it is incredibly satisfying it is certainly not easy.

Dust Collection

User / customer research, improve machine performance and lifespan, 4. work out your shipping systems, use social media, listening to advice and solving problems, money makes the world go round, how do i find customers for my cnc machining business.

It takes a lot to be successful in this game – and I’m here to walk you through the whole process so you can skip the common beginner mistakes.

There’s a lot that goes into running a CNC business that you might not have considered. You’ve got to have a solid plan for:

- Your start-up costs (machine and materials)

- Market demand (do people actually want what you’re selling)

- Pricing and margins (to make sure you can make a profit)

- Marketing (how are you going to get eyeballs on your product or service)

- Fulfillment (using systems to make sure you can deliver on your promises)

Now, that might seem a little daunting, but it’s all manageable if you just take it one step at a time. I’ll cover it all in this guide.

I’ll set you on the right track to making at least $1000 per month with your CNC business, and then we’ll touch on the next steps for scaling your project with staff members, workplace expansion, and outside investment.

Why Start A CNC Machining Business?

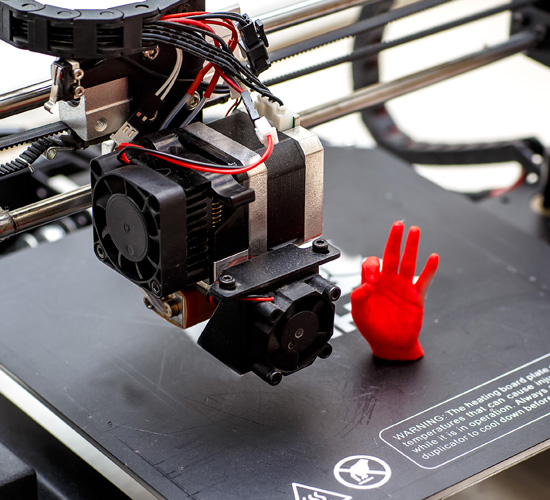

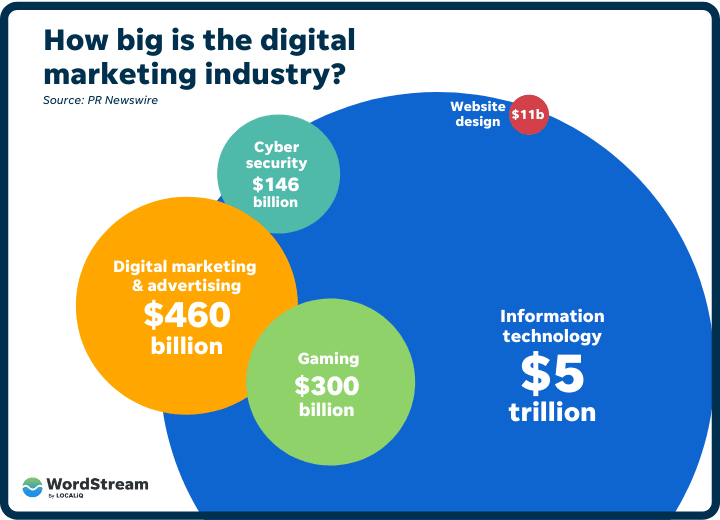

CNCs (including even lower-cost CNC routers) can now easily create complex designs and shapes, from home crafts to office supplies and kitchen implements to original signage, games, and toys.

CNC makers have total freedom to create products that are personalized and different, which makes them very popular on Etsy, Facebook Marketplace, eBay, Amazon, and independent brand e-commerce stores.

You’re not limited to a certain material, either: you can work with wood, plastics and acrylics, glass, and metal (with a strong enough CNC).

CNC products are also popular on social media platforms like YouTube and TikTok. At the press of a button, you can now showcase your designs to a worldwide audience, growing visibility and sales.

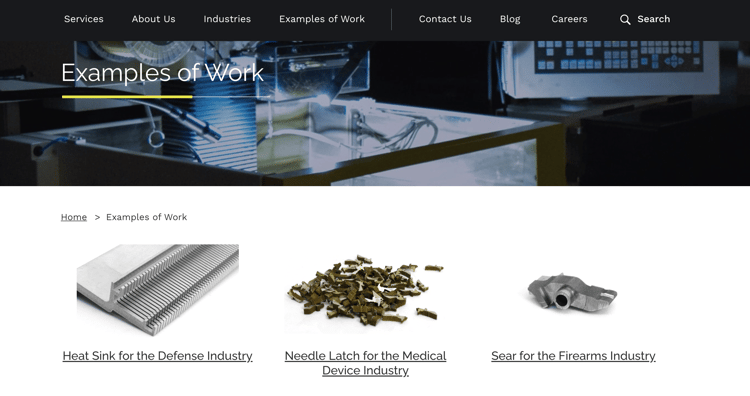

Beyond selling products to consumers directly, you can also supply products and parts for manufacturing businesses. Aerospace, automotive, medical, and electronics industries all rely on the type of high-quality, specialized components that CNC machining can produce

CNC Machining Startup Costs

First, let’s list some of the considerations you need to make to run a successful CNC machining business:

- Equipment: CNC machines, tooling, and work-holding devices.

- Facility: building construction or rent, utilities, and insurance.

- Employee: wages and salaries for machinists, IT, and administrative/financial staff.

- Raw materials: purchasing and stocking of materials.

- Hardware and software: office and workshop computers, internet, CAD/CAM software , and simulation tools.

- Tools and consumables: drill bits, cutting tools, lubricants, etc.

- Marketing and advertising: user research, market research, website design, and promotion of the business to potential customers.

- Legal and professional: obtaining licenses, permits, and other professional services.

When you’re starting out, the two key factors you’ll need to produce your products – consider are the machine you’ll be using, as well as the materials you’ll be using for your workpieces.

That’s the core of your business. After that, you’ll look to find ways to increase your output – either through automation techniques or delegating tasks to members of staff. But that comes later!

Choosing the Right Machine

The CNC machine itself will be your biggest outlay in the beginning. Depending on the machine, this can range from a few hundred dollars to hundreds of thousands of dollars for high-end machines.

Then there is the tooling, CNC software , and additional accessories you’ll need to consider to make things fully operational.

If you’re just starting up, you could consider outsourcing your CNC tasks to local shops to begin with, rather than investing in a CNC right away. You might only break even on your projects, but you’ll be able to assess how viable your idea is before taking any risk.

Where possible I highly recommend trying to borrow someone else’s machine for your first month or so, whether it’s a friend’s, a friendly company, or at a makerspace/hackerspace .

When you’re ready to invest, I highly recommend buying a used machine rather than a brand-new one to save on initial costs, and upgrade as you start profiting from your business. There are machine shops closing down all the time, and looking for machine shop auctions in your area is a great way to find a used CNC for cheap.

In terms of the machine itself, a used Haas machine would be an excellent choice. They’re powerful, easy to run, and are built like a tank. A used Haas machine will also hold its resale value, so you won’t lose much if you change your mind about getting into this business.

You can learn more about the best CNC machines for small businesses in our full guide – but whichever CNC you choose, consider the type of work you will be doing and how much of it you plan to do – so you don’t overspend.

You can easily start with a cheaper, less powerful and smaller CNC machine , and build up to large router or milling machines as you build your income.

Whatever your needs are, try and keep them focussed. Working with a tighter range of materials and product types means you don’t need as much different equipment, and there’s less of a learning curve for you (or any teammates).

P.S We have full guides for the best CNC routers for all of the most popular materials, including aluminum , and woodworking projects. Also, if you need to broaden your understanding of CNC technical terms, we also have a comprehensive guide on CNC terminology to help you.

I cannot stress enough how important it is to invest in a good dust collection solution.

It’s not just about keeping the workspace clean and tidy. The dust generated during the CNC process can wear out your equipment quicker, cause respiratory issues, and even lead to fires if left unchecked.

A vacuum cleaner simply won’t cut it if you plan on using your CNC machine for business purposes. You need a much bigger and better solution to effectively capture and filter dust particles. Trust me, you’ll thank yourself later if you invest in this early on.

I recommend a dust cyclone system connected to an impeller (~2HP) and 100mm (4″) piping, connected to a canister filter (preferably ~0.3-0.5 micron).

Additionally, at the spindle, it’s important to have a good dust shoe with compressed air to blow out the wood chips. This is because the 100mm piping will have low pressure but high volume, so it won’t be able to suck with as much power as a shop vac up close.

This is the system I use in my workshop, and while it may seem like an unnecessary cost when you’re just starting out, it’s going to save you money replacing damaged equipment in the long run.

Market Research

Market research is key when starting a CNC machining business. It’ll help you identify the potential demand for your products or your services, and help you understand the current industry trends. Some potential areas to research in the CNC industry include:

Market demand

Research which parts and products are most in demand in your target industries and your local market. Identify the customers that need CNC machining services and which applications they need most. This will vary depending on if you’re targeting B2B (local businesses as a service), or B2C (selling custom products to customers on Etsy or similar).

Industry trends

Keep informed about the latest industry trends. Watch emerging technologies, processes, and materials. Be aware of new standards, certifications, and regulations. For example, AI is almost certainly going to be built into CAD/CAM software over the next year , so learning good prompting for design will save you an enormous amount of time designing in the future.

Supply chain analysis

Make sure you’re familiar with how the supply chain of the CNC industry works. Research the manufacturers and suppliers of machines and raw materials. Look into potential suppliers that could reduce your costs, and think about how your workshop layout can be improved to make your processes more efficient.

Industry associations

Join CNC industry associations, both local and national. Attend events and trade shows. Get networking to advance your knowledge on best practices, technology innovations, and the latest industry trends.

Knowing your customers is an essential part of not only the CNC product development process but also understanding who your target audience is.

Applying some of the following steps will give you a better idea of these important requirements:

- Identify your target audience: Before anything else, you should have a clear idea of the audience you’re targeting. Perhaps you’re using your CNC machine to supply shelving, furniture, wall art, or candle holders for a domestic customer base.

- Conduct surveys: Conducting surveys can gather invaluable feedback from users. Structure survey questions to identify your target market’s preferences , pain points, and needs. Also, find out how easy it is to use existing products. This kind of feedback can provide better direction regarding design and service requirements.

- Carry out interviews: Interviewing your target audience gives you more in-depth insights about what your users actually need , and what they would prefer from your products or services. You can do this face-to-face or remotely, and either speak to a single person at a time or as a group.

- Analyze the data: Once you’ve collected the data from your user research, analyze it to identify important trends and patterns. Identify the main preferences, needs, and common pain points among your target audience.

- Build a user persona: Once you’ve analyzed all your data, you can build your user persona . This is a profile of your typical user, their age, demographics, buying habits, and personal needs – this is who you’ll focus on marketing to.

Use these insights you’ve gained through market and user research to find anything you can improve in your process, marketing, or whether you need to pivot to a different niche within CNC manufacturing.

Identify Your Unique Competitive Advantage

I’ll cut to the point: the CNC market is oversaturated.

It is easy to fall into the trap of thinking that you can open an online store, sell whatever you like, and become wealthy overnight.

You’ve seen guys on Youtube talking about how much money they’re making – sounds easy, right?

In reality, there are companies selling similar products for insanely low margins, and producing them far faster than you possibly could.

To convince someone to give you their money instead of a competitor, you need to identify a reason why they should.

You’ll have a chance to succeed if you can beat the competition in one of three areas

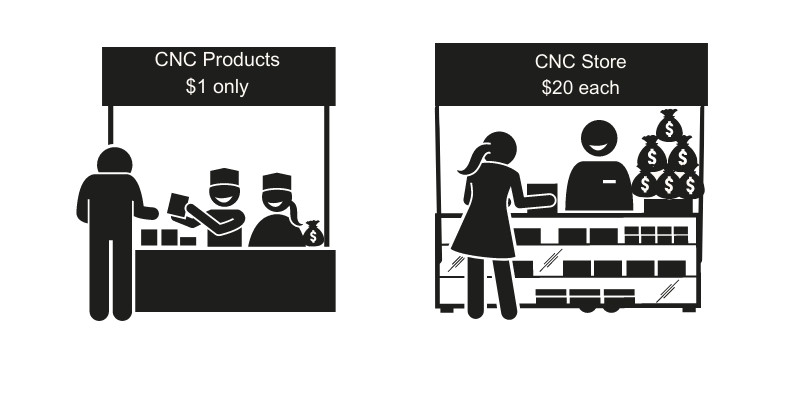

As a one-man army, you’re very unlikely to be able to compete on price. You’re battling against huge businesses that can buy their materials in bulk and outsource their labor incredibly cheaply. Do not try to match their margins.

And given the difference in machinery and infrastructure you have available compared to these huge corporations, you won’t win on speed either, unfortunately.

So that just leaves quality where can stand out and add value to the consumer

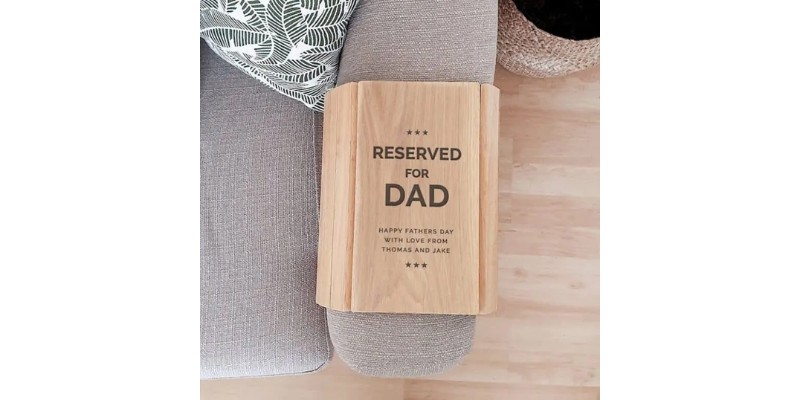

Quality is a broad term, but in this case, I’ll summarize it as something that people just can’t get elsewhere – which is either going to be something hyper-specific, or personalized so it is unique.

If people can’t get what you’re offering elsewhere, of course it’s the best quality option available – because it has nothing to compete against!

The best way to produce CNC products that sell as a beginner is to use your CNC expertise and design skills to produce one-of-a-kind products that your customers cannot find elsewhere.

Choosing Products That Will Sell

When it comes to deciding which products to focus on for your CNC business, you have to start by identifying a genuine need among potential customers.

Consider what problems you or others around you have that could be solved with anything a CNC machine could make. We’re looking for the intersection between the type of items you’ll be happy to work on every day, and what people are actually willing to pay for!

While there may be competitors with larger machines and cheaper labor, you can set yourself apart by offering a unique product that can’t be easily found elsewhere.

Remember, the CNC machine itself is just a tool – the real value lies in the product you create with it.

Pick Something You Can Build a Range Around

It’s much easier to convince people who have already bought from you to buy again than it is to find new customers.

So, your focus should be on giving your customers a good experience , and then retargeting them with other products they might be interested in.

Be specific, because you’re going to have to brand this at some point. Think about products that consumers might buy together to increase your average order value (AOV).

Repeatable Products

It’s also worth considering the potential for scalability and the opportunity to produce large quantities of a particular product.

The more repeatable the production process, the more efficient you can be, ultimately leading to increased production output and profitability.

One way to achieve this is by choosing products that have a consistent design and require minimal setup changes between runs. You do NOT want to be using new equipment, tools, or software for each individual order – keep things consistent.

This is much more scalable than a business that relies on producing original custom art for every order or having to adapt to a new material type for each engraving.

When it comes to pricing your CNC-produced products, it is important to strike a balance between pricing and production efficiency. You don’t want to spend too much time and effort on a product if the profit margins are too low.

That’s why I recommend personalized products where you can charge a premium price. You get rewarded in line with the unique value you can bring to the market, and customers are willing to pay extra for something that’s tailored to their specific needs and tastes.

You’re going to need to sell relatively expensive products to generate enough margin to make a good income – so make sure your core offer is at least $50 per product.

Trust me, no one ever got rich making $1 per sale from $10 products. You just won’t have the resources you need to sell enough products to make a living if you’re lurking in the bargain basement.

So that’s your core offer – but even with that in mind, you’ll want to consider a couple of cheaper add-on products that your ideal customer might also be interested in adding to increase your average order value.

Analyze your competitors

Analyzing your direct and indirect competition in the CNC industry is complex and time-consuming, but essential for learning how to market your business, and shows you what’s working well for them.

- Identify key players: Research the key international players within the CNC industry. Companies like Haas , Mazak , Okuma , and some others may not be in direct competition as they manufacture CNC machines, so these aren’t as useful to study. Instead, if you’re starting a CNC service, investigate successful machining services close to you.

- Marketing research: Look at their websites, social media, public client lists, SEO strategy, and lead generation forms. Note what looks good, and what looks to be working well.

- Research pricing: See what your competition charges, and whether you can realistically compete here (or if you need to compete on quality, or in another area instead).

- Look at competition trends: Look closely at those of your anticipated direct competition and see how these may have changed over time. This will give you insights into whether you can expect increases or decreases once you begin trading and into the future.

- Assess market share: Look at the market share of your direct opposition. You’ll get a better idea of which businesses are dominant, and what they’re doing right that got them there — so you can replicate this.

- Consider the competition’s customer base: It helps to know what customers your competition is focused on. Logically, if they’re direct competitors of yours, you’ll want to convince some of those customers to move across to your business.

Try to understand your competition and their pricing and systems. In that way, you’ll be more informed regarding strategic planning and when you buy and sell, or operate as direct competition on projects.

Stay on top of trends in CNC (and new technology)

Staying on top of CNC machinery technology lets you get more efficient, and provide the highest-quality products and services. In this way, you’ll stay competitive within the industry and cater to your customer’s ever-changing needs.

Consider the following to grow and maintain a foothold in the CNC machinery sector you choose:

Reduce potential damage through upgrades

CNC machinery is evolving all the time. Upgrades, such as to a vacuum table, for example, reduce any chance of collision with workpiece holders, and is better for keeping your machines in good shape as well as health and safety.

Enhance speed and scope with multi-axis, modular machinery

Multi-axis CNC laser cutting, milling, and waterjet machines are getting cheaper as technology improves. The best multi-axis CNC machines can cut two parts at the same time, while others can cut and perform another task like boring simultaneously.

Granted, one of these machines may still be too costly for a small business, but it is worth staying on top of the technologies.

If you are able to utilize more axes in workpieces, you’ll reduce the time of setting up your machine and can tackle more complicated tasks (that are often the most profitable projects).

Sensors have become more efficient and affordable, with many companies in the CNC industry incorporating them into their current systems. This helps increase the performance and lifespan of the machines.

By connecting CNC machines to the Industrial Internet of Things (IIoT), businesses can take advantage of a network that combines both software and hardware. This allows them to share and use data more effectively, ultimately improving their operations. If you have a CNC business, you can likely benefit from using IIoT technology for your sensor and data-sharing needs.

How to Sell Your Products

If you’re new to selling CNC products, I recommend getting started with Etsy.

It’s a super easy platform designed for selling custom-made products, with a good stream of built-in traffic to help you get some initial exposure and acquire your first few customers.

From there, you can look to build out more “sophisticated” marketing strategies (more on that in a second), but for now, the name of the game is gauging demand for your products and getting the ball rolling with your first few sales.

You can have your first few listings up within an hour or so – and it’s a really good way to test the waters.

The feedback you get from customers around pricing, quality, and ideas for new products or tweaks to your existing offer can be really valuable before you go ahead and invest a load of time and money in your own website or a paid marketing campaign.

My Top Tips for Etsy

1. run sales.

I generally find that running sales on Etsy helps my listing get more exposure and generate more sales, so I recommend pricing your products a few dollars higher than you would otherwise and running frequent promotions (somewhere between 10-20% off is enough)

2. A Picture Says a Thousand Words

It’s really important to take high-quality photos of your products to help them stand out on the search page.

Professional-grade camera equipment will get you the best possible results, as well as staging “action shots” of your products to help your customers get a real sense of how they look in real life.

- Photograph in natural light – Using natural sunlight assists with soft lighting that can improve how your item looks. Try capturing images outside or by an open window. Starting with good lighting means you won’t need to use flash on your camera. Camera flash creates harsh lighting with dark shadows and an unnatural appearance.

- Creatively compose your images – Capture multiple images in different environments to find the best setting to showcase your item.

- Take different types of shots – To showcase your products, you can take different types of photographs to show it in different settings and contexts.

- Leave space around your items – Take your picture from a far enough vantage point where you can see the entire product with extra negative space around your product. This will help when you crop the thumbnail of your listing photo.

- Take photos horizontally – When you upload your photo, a horizontally oriented picture means you’re able to use more of the available space within the thumbnail frame. Vertical images will require more information to be cropped out.

- Clean your camera lens – A dirty camera lens will prevent the ability to capture crisp images that properly focus on the product.

- Try not to zoom – Using the zoom feature on mobile devices and cameras usually results in a digital zoom, which produces a lower-quality image being captured. Instead of using zoom, physically move closer/further away from your item.

3. Optimise Your Titles and Descriptions

You also need to make sure your titles and descriptions follow best practices so that your items appear earlier in search results. Make sure to include all the relevant details in your product descriptions, such as dimensions, materials, and colors in your listing, because customers can search through categories based on these criteria.

(Check the Etsy Sellers Handbook for their official recommendations to have the best chance of attracting more eyeballs).

Last but not least – fulfillment. At the end of it all, you have to get your products in customers’ hands.

Packing, shipping, and dealing with customers can be a time-consuming and challenging part of running an Etsy shop.

Like producing the products themselves, the easy way to take the pain out of shipping is through a repeatable and systemized process.

I like ordering my packaging supplies in bulk to save time and money, and schedule my deliveries for home pick up a couple of times per week so I’m not always taking trips to the Post Office.

Other Ways to Market Your CNC Business

When you’re ready to take the next step, there are a number of other ways you can invest to grow your new CNC business.

Some more advanced ways you could consider marketing your CNC brand include:

Build a professional website

A top-class website that stands out is a great place to start your marketing efforts. It should aesthetically appeal to visitors, while also being easy to navigate. Provide them with relevant, authentic information about your product and services, as well as your personal backstory (and if applicable, your team’s). Include any awards you’ve won, any publications you’ve featured in, and anything else that builds trust, such as a Trustpilot or other score.

Use search engine optimization (SEO)

If your target audience is searching on Google for local suppliers or businesses, you want to show up first. For local SEO, make sure you have an optimized NAP (name, area, phone number) on your Google Business Profile, and build citations on local directories and industry directories.

And for more general content, create content around the keywords your customers are searching, but also be realistic in what you target — you’ll unlikely outrank Haas for CNC questions as they’re a huge brand with a strong backlink profile. Try to get links from your partners and suppliers, and make sure your site loads fast and is mobile-friendly.

Develop targeted marketing campaigns

With the user research you’ve carried out, devise marketing campaigns. These should speak to your audience’s needs and desires implicitly. Targeted online advertising, direct email campaigns, and website landing pages are all effective for the right audience.

Social media platforms like Facebook, Instagram, LinkedIn, and Twitter can be effective marketing tools. Share photos and videos of your work and processes, and post updates about your current projects and your capabilities. Engage with potential customers via forums, groups, pages, and threads to generate further interest in your brand.

CNC Tool and Machine Mastery

A CNC machinist needs to be a highly-skilled technical operator. You’ll need skills in areas like product design, CNC programming, planning, and quality control. Add the right blend of creativity, reasoning, time management, and problem-solving to the mix — and you’ll be an exceptional CNC machinist and manager of staff.

As you develop your skills, you’ll be able to competently produce more complex designs that you can charge more and achieve a better margin with.

The following traits and skills (among others) will help you and your employees to be successful in the CNC field:

Before you’ll be successful at anything, you need the desire to master it. Without the desire to do something properly, you’ll likely not excel. The other skills and traits on this list won’t matter as much without desire. You need to set yourself high standards and hold your team to those same standards.

Practical aptitude and abilities

As a CNC machinist, you’re going to need to handle tools and display an understanding of the principles of engineering. You may need specialized knowledge of certain CNC machining. Without the aptitude and practical ability, it’ll be very difficult to familiarize yourself with the machine or your role.

Math skills and knowledge of software

You’ll also have to be able to make sense of numbers and math problems to understand models and drawings. You’ll also need expertise in CAM and tool path strategies. You’ll often switch offsets in diameter, for example, to keep the size of cuts exact. You’ll also need to understand CAD, simulators, quality control, audit tools, and file management, among others.

Concentration and attention to detail

As a CNC machinist, you will need to concentrate. The world around you may be going mad, but your single-minded focus on what you’re cutting is needed. You should have the ability to envisage potential problems to make you a great machinist.

If you’re able to identify problems and solve them on the fly, you’ll succeed. It’s all part of the learning curve, and if you have the aptitude for the work, you’ll pick this skill up quickly. While it’s important to solve problems well, listening to co-workers is essential.

Reinvesting in Your Business

First and foremost, the most important investment you can make in your CNC business is making yourself more available. Your first goal should be to use the profits of your CNC business to make a living, so you can decide whether you want to quit your job and dedicate more of your week to growing your enterprise.

Once you’re full-time on your entrepreneurial grind, there are a number of other steps you can take to increase your output and scale your income even further.

The three main levers you can pull are:

- Equipment – High-quality equipment and tools will increase efficiency and reduce downtime.

- Building a team – Hiring reliable and skilled people will allow you to increase output, and buy back more of your time to work on the business, rather than in it.

- Workspace – Expanding into larger premises, or optimizing your layout to improve workflow and minimize wasted space.

When choosing the right time to buy, consider the potential time-saving benefits that the equipment will provide.

A basic CNC machine can be a good stopgap to cover you across a variety of tools, but if you have the capital it’s a good idea to invest in purpose-built tools for more efficient machining.

For instance, you can plane materials by running a surfacing pass on your CNC, but it will take longer, and the final “straightness/squareness” will depend on the flatness of your cutting surface and the calibration of your CNC machine.

And while you can get away without a bespoke joiner if you’re working with thinner woods, you’ll need to invest in the proper tool if you want to graduate beyond that.

The right tools will give you better results and free up your CNC machine for simultaneous tasks.

On that note – CNC machines can be quite slow, and detail work can take hours per piece. So even if you decide you really need a joiner or planer, you might just consider investing in another CNC machine anyway to increase your output.

However, if you find yourself needing square stock, and it takes too much time to wait for either your CNC or your turn at the planer, then it might be time to invest in additional equipment.

As your CNC business grows, you may find yourself in need of extra hands to keep up with the demand. But when is the right time to hire new staff?

One sign is when you start turning away work due to lack of capacity, and or are consistently struggling to find time for important tasks like customer care, inventory management or packaging orders.

When it comes to hiring, experience is important, but so are soft skills. Ideally, you want someone who not only knows their way around a CNC machine but also has good communication skills, can work well in a team, and is open to learning new things.

When evaluating potential hires, ask about their previous experience working with CNC machines, and ask them to demonstrate their skill – we can all bluff in an interview, but a trial day doesn’t lie.

In addition to technical skills and communication abilities, it’s also important to consider the individual’s work ethic. CNC work requires attention to detail, patience, and persistence. A good candidate should be willing to put in the effort and time required to ensure high-quality results.

As your CNC business grows, you may find yourself running out of space in your home workshop or communal workspace. While these spaces may be convenient and cost-effective in the early stages of your business, they come with several drawbacks that can limit your potential for growth.

Working from a home workshop may seem like an attractive option for cost savings, but it can lead to distractions and interruptions that can hinder productivity. There are safety concerns to consider when working with heavy machinery which may not be adequately addressed in a home workshop.

Similarly, communal workspaces may have limited access to equipment and resources, which can impact your ability to complete projects on time.

To overcome these limitations and take your CNC business to the next level, it may be appropriate to expand your work premises and move to a dedicated warehouse.

With a larger workspace, you can increase your production capacity, take on larger projects, and improve overall efficiency, leading to increased revenue and profitability.

When considering a move to a larger workspace, it’s important to consider the location, size, and layout of the new facility.

You’ll want to ensure that it’s easily accessible for your employees, suppliers, and customers, and that it has sufficient parking and loading/unloading areas for your equipment and materials.

Expanding Your CNC Business Through Investment

If this is your first CNC business, I strongly recommend starting small. Save up a little, and invest that money in the essentials and grow at a manageable pace.

If you’re up and running and are having some success, you may consider trying to find some outside investment to turbo-charge your growth.

For that, you’re going to need a compelling business plan.

Lenders or investors need to see you’ve got some business sense and will invest the money prudently, and understand the expected returns for that investment.

This means drawing on all the research you’ve done and collating it into a single document that inspires trust.

Let’s take a look at what you should include:

Who Are You?

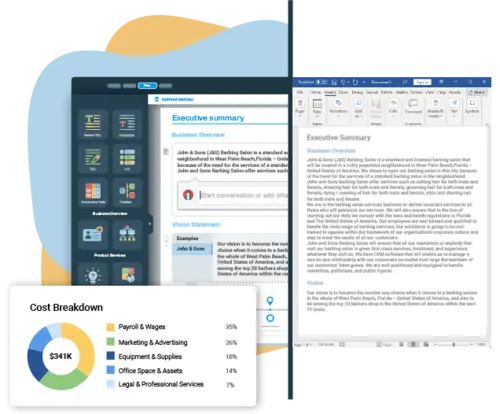

- Executive summary: You should open your plan with an executive summary. With this, you provide an overview of your CNC machining business, including a mission statement, financial projections, and proposed target market.

- Company description: Your company description should detail the types of CNC machining services you’ll offer, the products you’ll make, etc. Don’t confuse people with jargon and nonsense — try to explain everything as simply as possible, but without sacrificing detail. Also, mention the potential location of your CNC machining business. Include anything from your working history that will support your suitability to run a small business or a large one — investors need to trust your expertise and that you know what you’re doing.

What Do You Offer?

- Research and analysis: The research you’ve done comes in handy now. You should include the results of the analysis you’ve done from your research into the CNC market and its trends, your competition, and your target audience. Detail the type of research you’ve carried out, and summarize how it leads to your confident projections as a result. This is an important part of your business proposal. It shows financial institutions or potential investors how thorough you are as a business owner.

- Services and products: Describe in detail the specific CNC services and products you’ll offer. You might be manufacturing prototypes for business or custom parts through a custom manufacturing shop. If you are going to involve your business in the design of products for customers, mention this fact. List and define any other services, such as consulting for manufacturers, that you also intend to offer.

How Are You Going to Execute?

- Marketing and sales: Show how you’ll reach your audience and how you plan on keeping them once they’ve approached you. Provide insight into your website, your online marketing, and your physical marketing. Define your brand in detail and add samples of promotional materials and links where possible. You need to convince those reading your plan that you’re in the process of founding a successful CNC machining business.

- Operations and management: Banks need to know about your plans for hiring and any other processes. Also show how you’ll be able to manage your team efficiently. Give a detailed breakdown of the technology and equipment your new business will have. This way you’ll provide insight into the quality of work you’ll be able to produce.

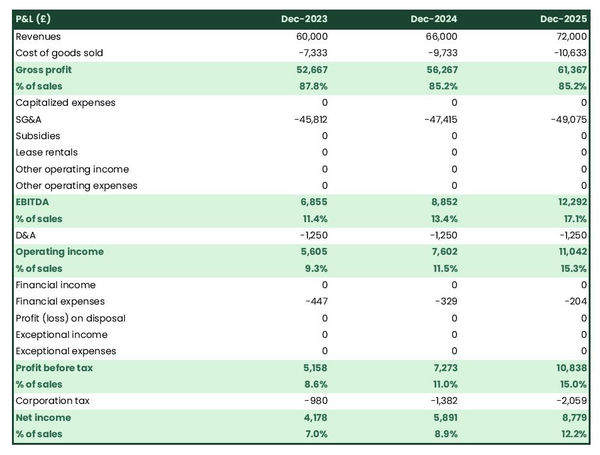

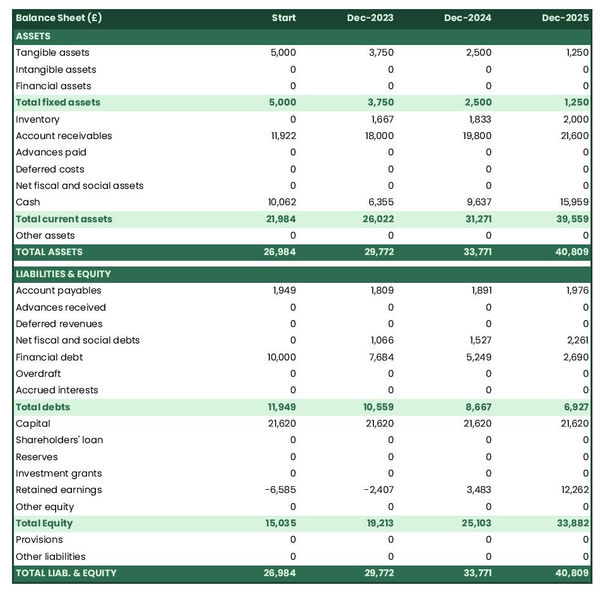

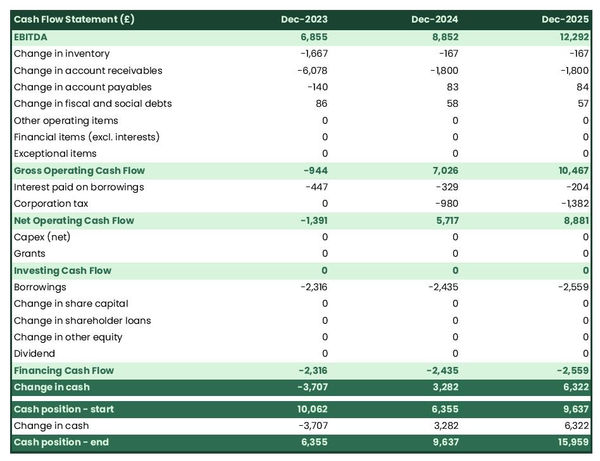

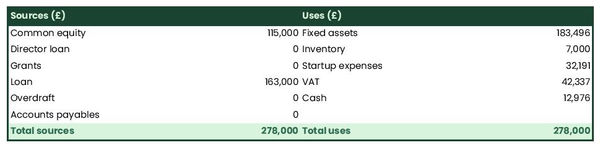

- Financial projections: You’ll want to be as detailed as possible here. Include startup costs, cash flow projections, and profit and loss predictions over the next years, and any existing figures if you’ve already started the business. Showing you’re organized and fluent with the numbers is the most important thing you can do here. And be precise.

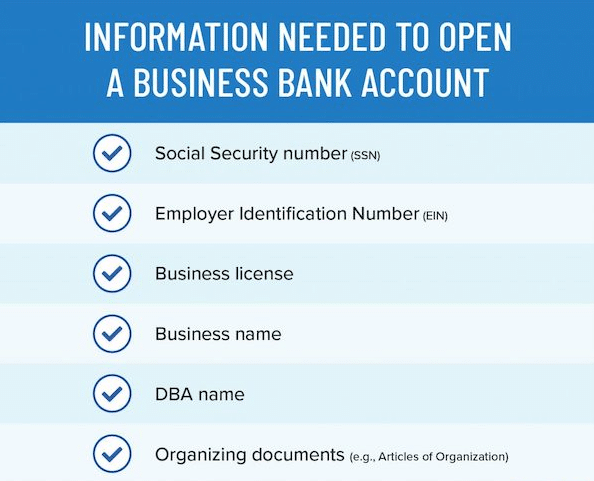

- Funding requirements: Give an outline of why you need the amount, and show exactly how you plan to use the money. Again, being precise is essential. A last tip on this point: make sure you include details of your business bank account.

Do I need any special certification or training to start a CNC machining business?

No, you don’t need any formal training or certification to start a CNC machining business! Though, if you have experience in engineering, machining, or a related field, this will definitely come in handy. You’ll likely have to apply for a business license and any local permits to operate heavy machinery, and you’ll also need a taxation number.

What are some challenges I could face if starting my own CNC machining business?

A common challenge you might face when starting a CNC machining business is finding skilled employees and retaining their services. It can also be challenging and expensive to keep up with the latest technologies and equipment while managing cash flow and costs.

Plus, it can be demanding to balance the production capacity of CNC machining with customer demand.

Network with other businesses and attend trade shows and industry events. Create an online business presence on social media and through a website. Keep your services excellent, and your pricing competitive.

Final Thoughts

Starting a successful CNC machining business requires careful research and planning. You’ll need to identify your direct competition, your target market, and your services and pricing structures, plus you’ll also need to know how much does a CNC cost . Follow this by developing a market strategy based on the findings of your research. Only then should you select the equipment you need and identify your future staff.

Establish a business proposal and approach financial institutions or investors – be sure to include your skills and certifications.

If there’s any way we can be of assistance from the beginning of the process to the end, feel free to contact us and we’ll guide you through CNC machining.

Was this content helpful? Give us your feedback here.

Share this:.

Learn More About CNCSourced

How to Laser Engrave Tumblers in Lightburn

11 Best CNC Software 2024 (Router Controller, CAD-CAM)

40+ CNC Industry Stats & Facts (2024)

The BEST Black Friday CNC Router/Machine Deals 2023

10 Essential CNC Router Accessories in 2024

10 Industries CNC Routers Are Used In

4 Best Laser Cutters For Acrylic in 2024 (All Prices)

4 Best Wood Laser Cutters & Engravers For Crafts 2024

4 Best Laser Engravers For Glass Etching 2024

The BEST Black Friday Laser Cutter & Engraver Deals 2023

9 Great CAD CAM Software (For All Uses) 2024

8 Best Nesting Software For Laser Cutters (Free & Paid)

Raster vs Vector Engraving: When To Use Each Type

How Hot Is A Laser Cutter? Simply Explained

xTool S1 Review: Best Professional Diode Laser Cutter

xTool F1 Review: the BEST Laser For Craft & Trade Shows

xTool P2 FULL Review: It’s Better Than Glowforge & Gweike Cloud

Snapmaker 2.0 Review – Laser & CNC Toolhead Test

The most informative CNC site on the web

[email protected]

CNC Routers CNC Machining Laser Cutters Software Rankings Reviews Comparisons Guides

Most Popular

Best Laser Cutters Best CNC Routers Best Cheap Laser Engravers Glowforge Alternatives Best Laser Engravers For Metal Best CO2 Laser Cutters Best CNC Mills Best CNC Machines For Small Business Best DIY CNC Routers Best 4x8 CNC Routers

Useful Links

About us About the team How we do our reviews Careers Contact Us

Sign up to our newsletter

Privacy policy

Terms and conditions

Affiliate disclaimer

Cookie policy

GDPR policy

Modern slavery statement

Accessibility

Complaints policy

Code of ethics

Editorial policy

How to Start a CNC Machining Business

Many products that businesses use and sell are made through a highly precise process called computer numerical control (CNC) machining. CNC machining businesses specialize in this type of manufacturing, which uses computer-controlled machines to produce products with a high degree of accuracy.

Learn how to start your own CNC Machining Business and whether it is the right fit for you.

Ready to form your LLC? Check out the Top LLC Formation Services .

Start a CNC Machining Business by following these 10 steps:

- Plan your CNC Machining Business

- Form your CNC Machining Business into a Legal Entity

- Register your CNC Machining Business for Taxes

- Open a Business Bank Account & Credit Card

- Set up Accounting for your CNC Machining Business

- Get the Necessary Permits & Licenses for your CNC Machining Business

- Get CNC Machining Business Insurance

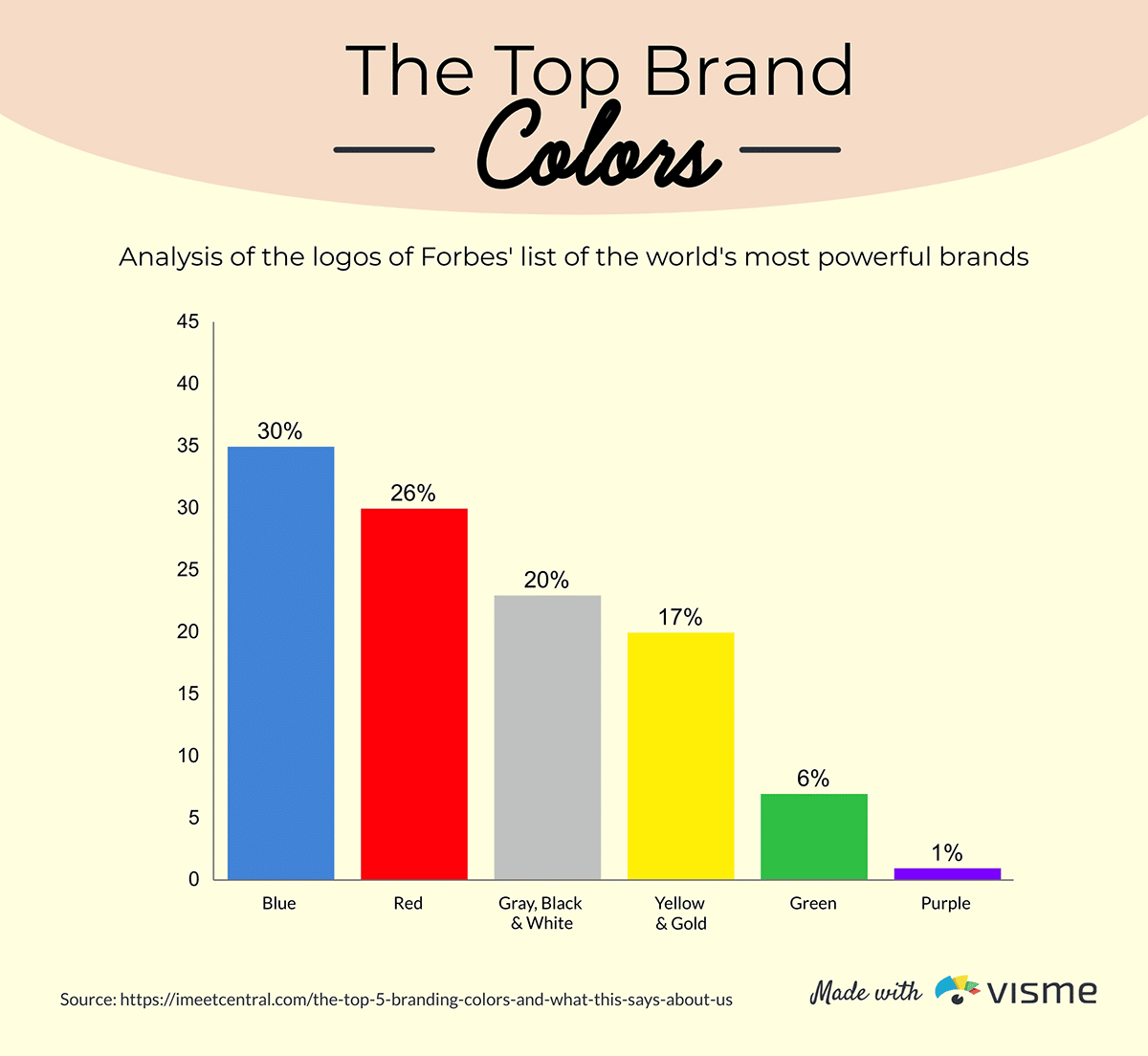

- Define your CNC Machining Business Brand

- Create your CNC Machining Business Website

- Set up your Business Phone System

We have put together this simple guide to starting your CNC Machining Business. These steps will ensure that your new business is well planned out, registered properly and legally compliant.

Exploring your options? Check out other small business ideas .

STEP 1: Plan your business

A clear plan is essential for success as an entrepreneur. It will help you map out the specifics of your business and discover some unknowns. A few important topics to consider are:

What will you name your business?

- What are the startup and ongoing costs?

- Who is your target market?

How much can you charge customers?

Luckily we have done a lot of this research for you.

Choosing the right name is important and challenging. If you don’t already have a name in mind, visit our How to Name a Business guide or get help brainstorming a name with our CNC Machining Business Name Generator

If you operate a sole proprietorship , you might want to operate under a business name other than your own name. Visit our DBA guide to learn more.

When registering a business name , we recommend researching your business name by checking:

- Your state's business records

- Federal and state trademark records

- Social media platforms

- Web domain availability .

It's very important to secure your domain name before someone else does.

Want some help naming your CNC Machining Business?

Business name generator, what are the costs involved in opening a cnc machining business.

CNC machines aren’t inexpensive. Lathes alone can cost anywhere from a few thousand dollars to tens of thousands, and many shops have several pieces of equipment. Nevertheless, there are ways for business owners to keep their startup costs relatively low -- and it’s possible to start a CNC machining business for very little.

First, many business owners start out working from their garage or a workshop that they already have. This eliminates the need to lease a workspace until there’s regular work.

Second, business owners don’t need lots of equipment or the fanciest available equipment when first getting started. For example, Todd Adlon opened his shop with just a mill and a lathe, adding equipment later on. Several other business owners got started with just a basic lathe.

Having only basic equipment will limit the amount and type of work that a CNC machining business can do, but there’s enough basic work available to support a small shop that has only one or two machines. Specifically, there are lots of clients who need prototypes made, and larger shops often won’t make one-off prototypes.

What are the ongoing expenses for a CNC Machining Business?

The ongoing expenses for a CNC machining business can be substantial. They include raw material costs, utilities, equipment maintenance costs, lease payments, and employee salaries.

Who is the target market?

Most CNC machining businesses serve other businesses, although a few make products that are directly marketed to individuals.

Business-to-business machine shops can be divided into two categories: job shops and product shops . Job shops take orders from clients and then make items that are built to their client’s specifications. Product shops design and create their own products, then sell those products to businesses.

How does a CNC Machining Business make money?

A CNC machining business makes money by selling machined parts. Prototypes may be sold as single items, but most orders are for large quantities of the same part.