Root-Cause Problem Solving in an Industry 4.0 Context

Ieee account.

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Root-cause problem solving in the Ops 4.0 era

Passionate about the “human factor”: helping people develop broad skills and deep functional expertise. Experienced operations practitioner, faculty member, and author.

Wouter Michiels, a consultant based in the Brussels Office, has more than 10 years’ experience in petrochemical manufacturing, engineering, and supply chains.

April 15, 2019 To improve, organizations must consistently seek out and solve their problems—an insight that underpins lean management ’s emphasis on root-cause problem solving (RCPS). Indeed, companies that have used RCPS to build a problem-solving culture that lasts are able to avoid continuous firefighting by effectively preventing fires from starting.

But RCPS takes discipline and patience, which some leaders resist: a manager may be reluctant to use this model if she’s convinced that she has already identified an “operational solution.” Nevertheless, persuading her to join her team on a problem-solving journey can help uncover a more effective and sustainable set of solutions—most importantly by including the people who know the problem best: shop-floor employees. Their perspective often shows that the initial idea would not have addressed the problem’s real causes, and would have met with a lot of resistance from the people charged with implementation.

Ops 4.0 technologies are making it easier to overcome that resistance and invigorate root-cause problem solving performance. What follows is a non-exhaustive overview of how different technologies ( italicized ) could be applied in each of the five RCPS elements (exhibit).

1. Identifying and defining the problem

The rise of advanced analytics and business-intelligence applications allows companies can detect many more problems than in the past, and in a more effective way—so long as they have sufficient internal support to interpret the output . Examples include fraud detection in banking and insurance, as well as deviations from normal operating conditions of equipment in manufacturing plants. For the latter, the increased availability of high-frequency, high-precision sensors , together with the rise of the Internet of Things provides companies with larger data sets from which to identify problems.

2. Assessing root cause(s)

Once the problem is defined, root causes are often identified via the five-why methodology. Instead of using the traditional colored sticky notes to facilitate this exercise, companies can now use interactive whiteboards incorporating speech-to-text or handwriting-to-text algorithms, together with high-quality touch commands . Moreover, the whiteboards can link to data warehouses , thereby enabling self-service analytics or even machine-learning algorithms for performing the analyses required in confirming or rejecting potential root causes.

3. Designing solutions

Augmented- and virtual-reality applications can help designers’ creation process become even more productive. Faster iterations between the drawing board and a more real-life representation shorten lead times toward final design. Rapid prototyping and 3D printing can accelerate this process even further by bringing intermediate versions of the solution to life.

4. Testing solutions

Once a solution has been designed, it is crucial to test its efficiency and effectiveness. The increase in computing power enables companies to perform extensive computational simulations . Using digital twins helps organizations create virtual mirrors of their operations, allowing them to test ideas more realistically before implementation.

5. Sustaining, sharing, and continuously improving

The digital communication and collaboration platforms that are now in widespread use can often be linked with interactive tools such as digital whiteboards, minimizing the time teams spend on documentation so they can instead focus on the creative parts of problem solving. Having past records of problem-solving sheets available at only one touch avoids solving the same problem all over again.

The above list shows how the ancient art of root-cause problem solving can take shape in today’s environment. The question for most organizations is how to start, especially with technologies that can sound like science fiction. A learning center designed to replicate an actual, digitally enabled working environment can provide the first step, helping people experience the impact these technologies can achieve in a practical and realistic setting.

Connect with our Operations Practice

- Cloud Platform Build & Migration

- Enterprise Transformation

- Security and DevSecOps

- Cloud-Native Development

- Data Platforms and Analytics

- Case Studies

- Content Hub

How to Use Systems Thinking to Find and Fix the *Root Cause* of Your Organisational Woes

Systems Thinking is a tool for understanding complex systems—such as enterprise organisations—where no one person can see the whole, but where we must understand the whole in order to drive effective and long-lasting organisational change.

It provides a holistic way of diagnosing the root cause behind problems faced by our clients, and for identifying a targeted intervention that will provide long-lasting organisational-wide benefit—similar to how doctors diagnose their patients’ symptoms but then administer a cure targeted at the cause of the symptoms, rather than the symptoms themselves .

Problems we generally see our clients encounter include:

- Projects getting ‘stuck’ in software delivery, being delivered late or over-budget

- Value proposition being undercut by new industry players

- Growing focus on SaaS products because delivering software in-house becomes increasingly complex

- Leaders often needing to get involved with firefighting software delivery

- Consultants or contractors often required to bring in additional knowledge

At Contino, we see that a number of our clients’ challenges arise due to the pursuit of Scientific Management, a traditional—and still widely followed—management theory devised by Fredderick Winslow Taylor in the 19th century.

In this blog, we’ll explore Scientific Management, the implications on your business, and how Systems Thinking can help alleviate emerging challenges.

What Is Scientific Management and How Does it Impact Your Business?

Scientific Management places a razor-sharp focus on improving productivity in an organisation.

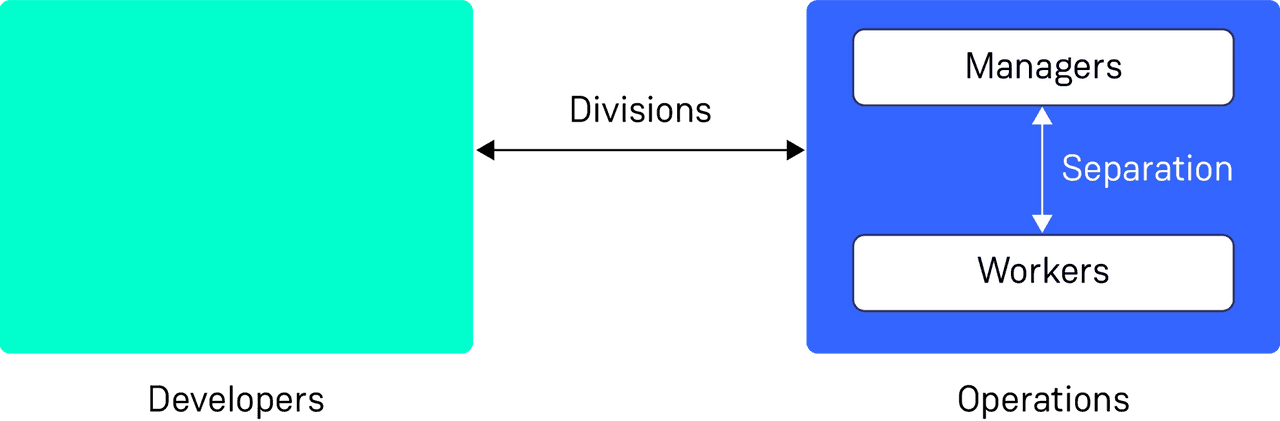

It does this by separating strategic thinking (managers) from tactical operations (workers), and dividing the organisation (often by discipline) to make it easier to optimise each individual part.

The above diagram illustrates how Scientific Thinking encourages horizontal division between departments (developers and operations) and vertical separation within departments between the ‘strategic thinkers’ (managers) and the ‘tactical operations’ (workers).

Whilst separation of strategic thinking from tactical operations, and the division of disciplines, provided some benefits in manufacturing where processes needed to remain fixed and predictable, it inhibits today’s organisations from being fluid and adaptable in dynamic environments. This has led to many of the challenges we work through with our clients.

Dividing organisations divides the knowledge and authority needed for effective problem solving across many isolated teams: designers, developers, customer services, finance, strategists and other parts of the organisations. In times of crisis, we often see these divisions temporarily bypassed, enabling cross-functional teams to form that can deliver big changes quickly. A recent example is the major supermarket chains Sainsburys and Tesco who are rapidly adapting their online and in-store operations in response to the shifting needs of staff and customers in the wake of coronavirus.

“Right now, your company has 21st-century Internet-enabled business processes, mid-20th century management processes, all built atop 19th-century management principles.”

—Gary Hamel

Let’s first look at two frequent challenges that result from Scientific Management - and their impact on the business - before exploring how Systems Thinking can help.

Challenge One: dividing disciplines constrains efficiency and effectiveness

Scientific Management has encouraged organisations to divide themselves by discipline. However, this has impeded effective problem solving - such as delivering software - which requires collaboration across many disciplines to be successful (e.g.: marketing, design, engineering, testing, security, operations).

By segregating the disciplines of an effective software delivery team - and attaching them to different management lines with different (and possibly conflicting) objectives - we reduce the opportunity for the disciplines to work together toward a common goal, and do the right thing well.

Collaboration is replaced with documentation, handoffs and work queues as the primary form of communication.

In these conditions of constrained collaboration, the ability to be effective (to solve the right problem) decreases as context does not naturally flow between teams, and therefore each team will have a different and limited understanding of the problem to be solved.

To be effective, all team members must share a common understanding of the problem and therefore take on a coordinated approach on the solution. This requires frequent, regular interactive collaboration, not handoffs.

As an example: let’s imagine a software team delivering a new app for a large enterprise in a waterfall context. In this enterprise setting, success is often perceived as the ability to satisfy the iron triangle (delivering on time, on budget and to scope).

In the face of the natural uncertainty surrounding any complex project, fixed scope and fixed deadlines, the team is encouraged to cut corners and lower software quality in order to deliver on time. The software will therefore require more handholding and manual workarounds, requiring greater time and cost from an operations team whose success is often measured by the cost of support. The ability to be efficient (solve the problem with the least waste) is also reduced, as rework and queue time is introduced between teams.

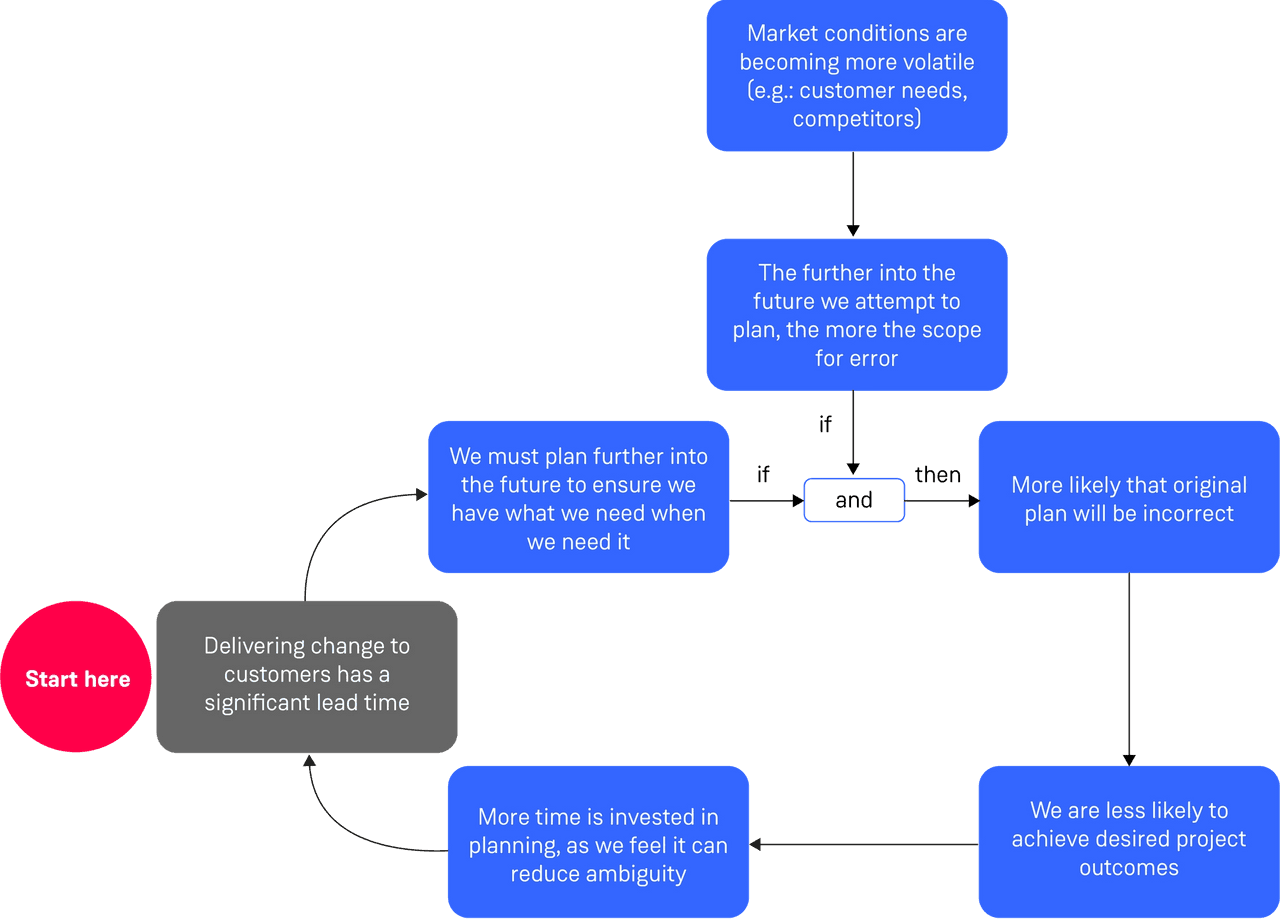

As the external environment becomes more volatile, uncertain, complex and ambiguous (VUCA), we see organisations doubling down on analysis and planning. The perverse effect of this additional upfront work is that it constrains our ability to be effective by further delaying customer feedback - which is vital to ensure we’re delivering the right thing.

The downward spiral of overplanning in a volatile environment, leading to reducing outcomes.

As our environment becomes more VUCA, we must be increasingly effective by ensuring teams have a shared understanding of the problem and by delivering value in small increments to customers - sensing and responding to their feedback as we go - and thus amplifying the effectiveness of what we deliver.

Challenge Two: Separating thinking from operations encourages misdiagnosis

Organisations are complex systems, where no one person understands the whole. They are interconnected, where one action often has multiple reactions - like pulling on the corner of a spider’s web.

As an example: a software team that wants to deliver value faster to their end users often must first break down their projects into smaller pieces. Breaking down projects into smaller pieces requires changes to how projects are defined, governed and financed, which in turn requires changes to how the software team collaborates with the wider business, e.g. how funding is divided and distributed, and how the success of the team and its members are measured.

Dividing and separating enterprise organisations into smaller pieces often does not reduce complexity, but instead reduces how much any one person can see and understand. Staff are therefore less able to identify and diagnose the real cause of problems they see, and to anticipate possible negative consequences of their actions. Hierarchy further compounds this complexity, distancing leaders and their vision from on-the-ground reality, and vice-versa.

Like a well-intentioned but misled doctor, complexity encourages leaders to continue on a downward spiral of misdiagnosis and incorrect treatment.

As an example: Deming talked of leaders who installed inspirational posters on factory floors encouraging “Zero defects!”, and measured workers on achieving such lofty targets. Unfortunately, the cause of defects often lay in the hands of management through not responding to worker requests to replace faulty equipment, or not supporting sufficient on-the-job training. Whilst leaders had misdiagnosed the cause as the need to motivate their workers, the cause actually lay in their not responding to workers’ requests.

If management sets quantitative targets and makes people’s job depend on meeting them, they will likely meet the targets – even if they have to destroy the enterprise to do it.

-- W. Edwards Deming

As we encounter symptoms, we must first find their cause. Responding to the symptoms directly wastes effort and compounds their effect - such as adding further gates to the governance process in an attempt to improve software quality, only to increase hand-offs and slow delivery - encouraging more corners to be cut.

Enter Systems Thinking

Systems Thinking is a method for understanding an organisation as a whole. It provides a way of identifying the real root cause behind the problems we observe.

Every system exhibits a multitude of symptoms. Logic suggests that similar symptoms are generally linked to a common underlying root cause. Solving the root cause will remove the symptoms in one go, whereas attempting to tackle the symptoms individually will generally offer temporary relief at most. This is similar to doctors - they do not prescribe one treatment per symptom, but instead prescribe a single cure for the underlying cause of those symptoms.

I smile and start to count on my fingers: One, people are good. Two, every conflict can be removed. Three, every situation, no matter how complex it initially looks, is exceedingly simple. Four, every situation can be substantially improved; even the sky is not the limit.

-- Eliyahu M. Goldratt

Systems Thinking is different from analytical thinking, which is the traditional way we’re taught to solve problems. Analytical thinking involves attempting to understand the whole by understanding each part in isolation, neglecting the interconnectivity. We cannot understand how a car operates—and how to improve its performance—by analysing each individual piece in isolation. We must understand how the parts interact with each other, and how those interactions can be improved.

As an example: improving the efficiency of developers in isolation will often not improve the speed or quality of software delivery in an organisation. Techniques such as Value Stream Mapping allow us to understand how value is delivered through an organisation: the teams, activities, handoffs and waste. Using this technique to visualise the entire process as a pipeline allows us to find the narrowest point in that pipeline, and invest our efforts there. Investing our efforts anywhere else will likely have no significant or long-lasting impact on the speed or quality of software delivery.

Similarly, analysis is ineffective for complex organisational problems: it does not give us a method for identifying the root cause behind the symptoms. It also does not allow us to connect our actions with their—often distant and unintended—effects, and therefore understand if we’re causing more harm than help to the organisational as a whole.

Systems Thinking with Our Clients: A Case Study

We regularly work with global enterprises to help them understand the root cause behind the symptoms they face within their technology divisions, such as: reduced throughput, overburdened operations team, attrition, conflict between areas and emerging shadow IT practices.

Our consultants have successfully applied the Theory of Constraints across industries, a Systems Thinking methodology for identifying and tackling the most important limiting factor—or root cause—that stands in the way of achieving a goal in a complex organisation.

Let’s use a recent global professional services organisation as an example.

The organisation was experiencing slow software delivery, impairing their ability to remain competitive in a dynamic marketplace. Contino was asked to perform a broad assessment to identify initiatives that would enable accelerated software delivery.

Their initial focus was on attempting to work around the symptoms, for example by buying SaaS products to deliver the necessary capabilities to remove the need to build them internally. This had the unintended effect of further increasing the complexity of their technology landscape and further slowing the delivery of future software projects.

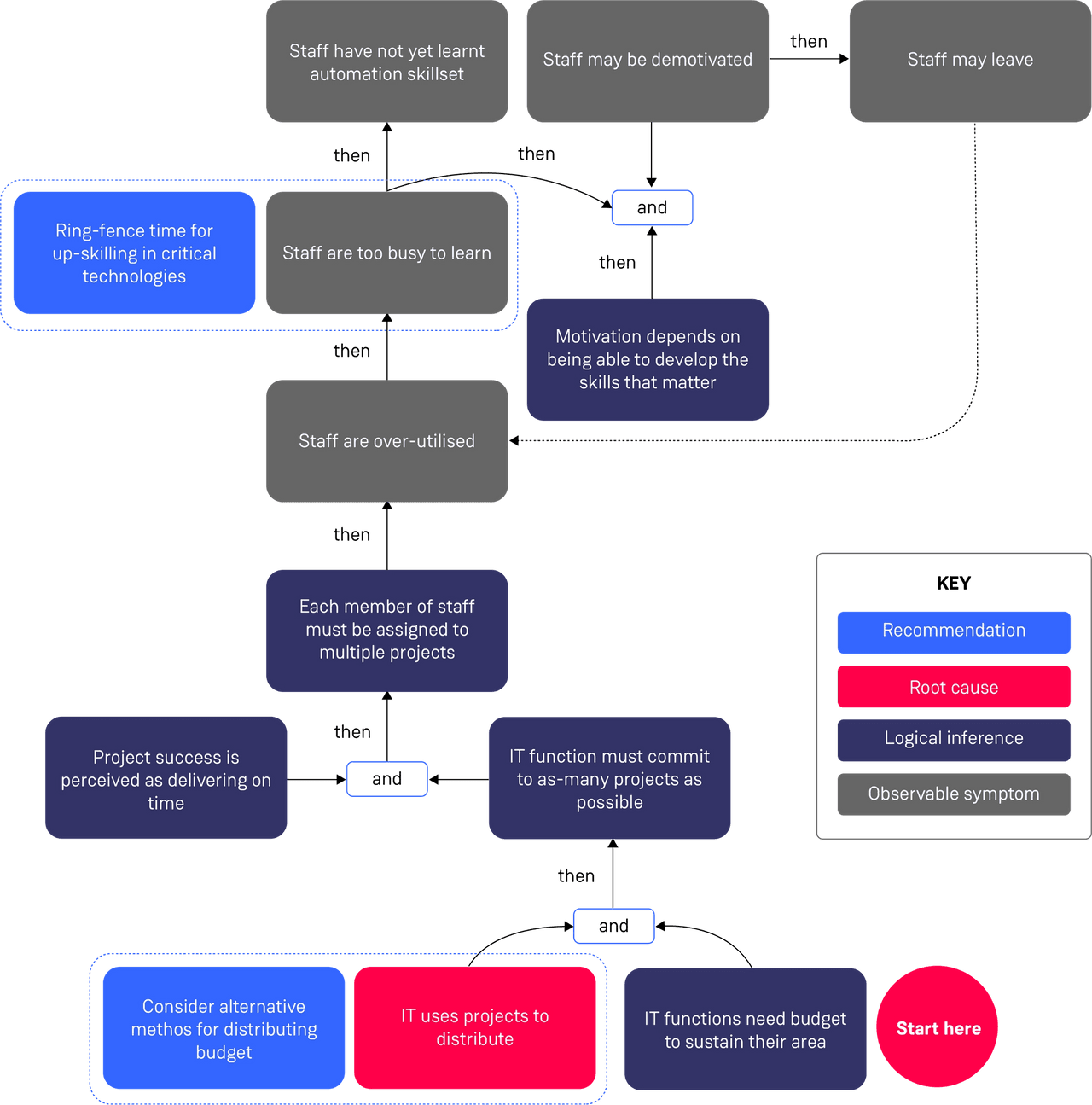

Contino held short interviews across the organisation to build a holistic understanding of the processes that were failing, and the human and technical factors contributing to their software delivery challenges.

The interviews helped surface that development teams hadn’t yet had the opportunity to build skill sets in the areas needed to accelerate software delivery, such as automation. This was not due to staff not wanting to learn, but due to the very limited time they had available outside of delivering against multiple projects. This staff busyness was in turn due to the head of each IT function needing to commit to as many projects as possible to maximise the amount of budget their area received, meaning each person then needed to be committed to many projects and be over-utilised, leaving no time for learning the skills that will help them deliver future projects faster.

As a result of this finding, we were able to propose a single, simple strategic recommendation of amending how budget is distributed across IT functions in a way that avoids overloading the teams with work.

And the outcome?

The annual project prioritisation process was changed, leading to the beginnings of increased collaboration across IT functions and paving the way for faster project delivery. We also observed continued use of systems thinking methods following our departure for understanding and communicating complex problems.

The Contino Systems Thinking Approach

The approach begins by gathering an understanding of the symptoms across the organisation, and how those symptoms interconnect. This is performed by interviewing staff and constructing a causality diagram (or ‘Current Reality Tree’). The diagram is also used as a story-telling tool that can be iteratively refined with staff through playbacks to validate our identification of the root cause of all symptoms.

The root cause usually relates to the processes or structure of the organisation, such as how work is defined, distributed or how outcomes are measured. These processes and structures often inform how people operate and solve problems, often implicitly influencing the behaviour - the ‘culture’ of an organisation. This makes any problems with the processes often harder to see, as they have become so embedded and tacit to staff.

This is where Systems Thinking can help identify and make explicit the processes that may require evolution to enable the organisation to remain adaptable, and - in doing so - influence the underlying culture.

Following the use of Systems Thinking we have observed leadership using the Current Reality Tree as an intuitive story-telling tool with their staff. We are also seeing the resultant beginnings of team building exercises, changes to the annual budgeting cycle - and are excited to support some of their ensuing grassroot change initiatives.

Further Reading

- “Why organisations get stuck, and how can you help” by Simon Copsey

- “Thinking in Systems: A Primer” by Donella H. Meadows, Diana Wright

- “It's Not Luck” by Eliyahu M. Goldratt

More Articles

Best Practices for MLOps and the Machine Learning Lifecycle

How to Hold Successful Value Stream Maps Remotely

FinOps: How Cloud Finance Management Can Save Your Cloud Programme From Extinction

This website uses cookies to maximise your experience and help us to understand how we can improve it. By clicking 'Accept', you consent to the use of these cookies. If you would like to manage your cookie settings, you can control this in your internet browser. Find out more in our Privacy Policy.

tableau.com is not available in your region.

Elasticsearch Platform

Observability, security, and search solutions — powered by the Elasticsearch Platform.

Search and analytics, data ingestion, and visualization – all at your fingertips

- Elasticsearch

- Integrations

Elastic Cloud

Find answers that matter with Elastic on your preferred cloud provider.

- Observability

Unify app and infrastructure visibility to proactively resolve issues.

- Log monitoring

- Application performance monitoring

- Infrastructure monitoring

- Synthetic monitoring

- Real user monitoring

- Universal profiling

- OpenTelemetry

Protect, investigate, and respond to cyber threats quickly and at scale.

- Continuous monitoring

- Threat hunting

- Investigation and incident response

- Automated threat protection

Accelerate search results across any cloud and increase personalization.

- Generative AI

- Search applications

- Workplace search

- Customer support

By industry

- Public sector

- Financial services

- Telecommunications

- Retail and Ecommerce

- Manufacturing and automotive

By solution

Give customers the flexibility, speed, and scale to find what's next.

Customer spotlight

Learn how Cisco transforms its search experience with AI

Learn how RWE powers its renewable energy trading business

Learn how Comcast boosts engineering velocity and innovation

Dive in to everything related to code, forums, and groups.

- Search Labs

Stay up to date with the latest tech topics, innovations, and news.

Grow your skills and open doors for future success.

- Getting started

- Elastic resources

- Consulting services

- Trainings & certifications

- Security Labs

Find the support you need, no matter the topic.

- Support center

See what's happening at Elastic

See our demo gallery

Get started with Elasticsearch

What's new in Elastic 8.13

- Start free trial

- Contact Sales

What is root cause analysis (RCA) in software development?

Root cause analysis definition.

Root cause analysis (RCA) is a proven troubleshooting technique used by software development teams to identify and resolve problems at their core, rather than attempting to treat symptoms. Root cause analysis is a structured, step-by-step process designed to seek out primary, underlying causes by gathering and analyzing relevant data and testing solutions that address them.

Why is root cause analysis important?

Root cause analysis is essential in software development because the systematic approach allows teams to troubleshoot more efficiently and develop long-term solutions that prevent issues from recurring. By addressing the root causes of errors and defects, developers can ensure their systems are stable, reliable, and efficient, reducing costly downtime and speeding up the development process. RCA also helps developers prioritize issues based on their impact and severity, empowering them to tackle the most critical problems first.

How to conduct a root cause analysis

Applied as a problem-solving method across industries and disciplines— from science and engineering to manufacturing and healthcare— root cause analysis requires following a specific series of steps to isolate and understand the fundamental factors contributing to a flaw or failure in a system. The steps involved in conducting root cause analysis in software development follow the same universal RCA principles:

- Step 1: Define the problem and set up alerts (if possible) The first step in RCA is to define the problem and make sure it’s clearly understood. This could include setting up alerts to monitor for potential issues like abnormal application behavior, system performance degradation, or security incidents.

- Step 2: Gather and analyze data to determine potential causal factors Once the problem has been defined, the next step is to gather and analyze data. This may include reviewing system logs, application performance metrics, user feedback, and other relevant data sources. The data evaluation should lead to a list of potential causal factors that could be contributing to the problem.

- Step 3: Determine root causes Once the data analysis in Step 2 is complete, use one of several RCA methods to analyze the data and potential causal factors to discover the actual root cause (or causes) of the problem. The root cause analysis should suggest corrective actions.

- Step 4: Implement solutions and document actions After the root cause has been identified, the last step is implementing solutions to address the problem. This may include changes to code, configuration settings, or any number of system adjustments. It’s important to document all actions taken to address the problem to ensure they’re effective and can be repeated if necessary.

Methods and techniques for root cause analysis outside of the software world

There are many useful tools developed to aid in achieving effective RCA. When brainstorming and analyzing potential causes, these methods allow you to visualize and organize information into a usable framework for solving problems. Popular techniques for root cause analysis include:

- 5 Whys The 5 Whys is a problem-solving strategy that helps get to root causes by iterating on “Why” questions until the immediate causes of a problem are identified. When teams ask" why" multiple times, with each question leading logically to the next, it encourages critical thinking and deeper digging, helping to prevent superficial or surface-level solutions.

- Pareto chart A Pareto Chart is a combination bar chart and line chart that maps out the frequency of the most common root causes of problems, starting with the most probable. Based on the Pareto principle, which states that 80% of the effects come from 20% of the causes, the chart lists causes in order of importance and shows the cumulative impact of each, helping teams prioritize the causes that have the most significant impact on the problem.

- Scatter plot diagram A scatter plot diagram uses dots to help teams identify patterns in data that could be contributing to a problem. Plotting two numeric variables on a graph makes it easier to find any correlation between them. The technique can help you quickly identify any significant relationships between variables and identify outliers, which could be the potential causes you're looking for.

- Fishbone diagram Resembling a fish skeleton, this visual tool provides a graphic representation of the factors that could be contributing to a problem, with the head representing the issue and the bones representing the categories of potential causes. It is particularly effective at fostering collaboration among teams and can help lead to a more comprehensive understanding of the problem.

- Failure Mode and Effects Analysis (FMEA) FMEA is a structured, empirical approach that helps to identify potential failures and their effects. It is a systematic method that involves identifying potential failure modes, evaluating their severity, and determining the likelihood of occurrence and detection — then ranking them by their potential risk score. It can help teams focus on the most important issues to tackle first and also help prevent problems before they occur.

Root cause analysis tools for software developers

In the software world, RCA can expose root problems deep in the code. But the use of cloud-native technologies and the complexity of today's modern applications make it increasingly difficult to determine the root cause of issues. Teams can use observability and security tools to achieve powerful RCA results, for example:

Observability Observability provides real-time insight into software performance and behavior through data collection and analysis, allowing you to identify issues and gain visibility into root causes by monitoring metrics, logs, and traces, and through AIOps and observability tools like:

- Machine learning and AIOps Search, visualization, and machine learning can help identify anomalies and surface the root cause of an issue. This can help you make informed decisions and take corrective action quickly.

- Distributed tracing Tracking and analyzing the flow of requests through complex distributed systems with distributed tracing provides insight into the interactions between components and services, which can help identify bottlenecks and other issues that could be causing problems.

- Log pattern analysis Analyzing log patterns and trends generated by applications and infrastructure to identify the root cause of a problem—as well as detect anomalies, errors, and other issues that could be impacting software performance.

- Service dependency mapping By identifying the relationships and dependencies between different components in a system, you can automatically map service dependencies that might be causing issues and understand how changes in one component impact the rest of the system.

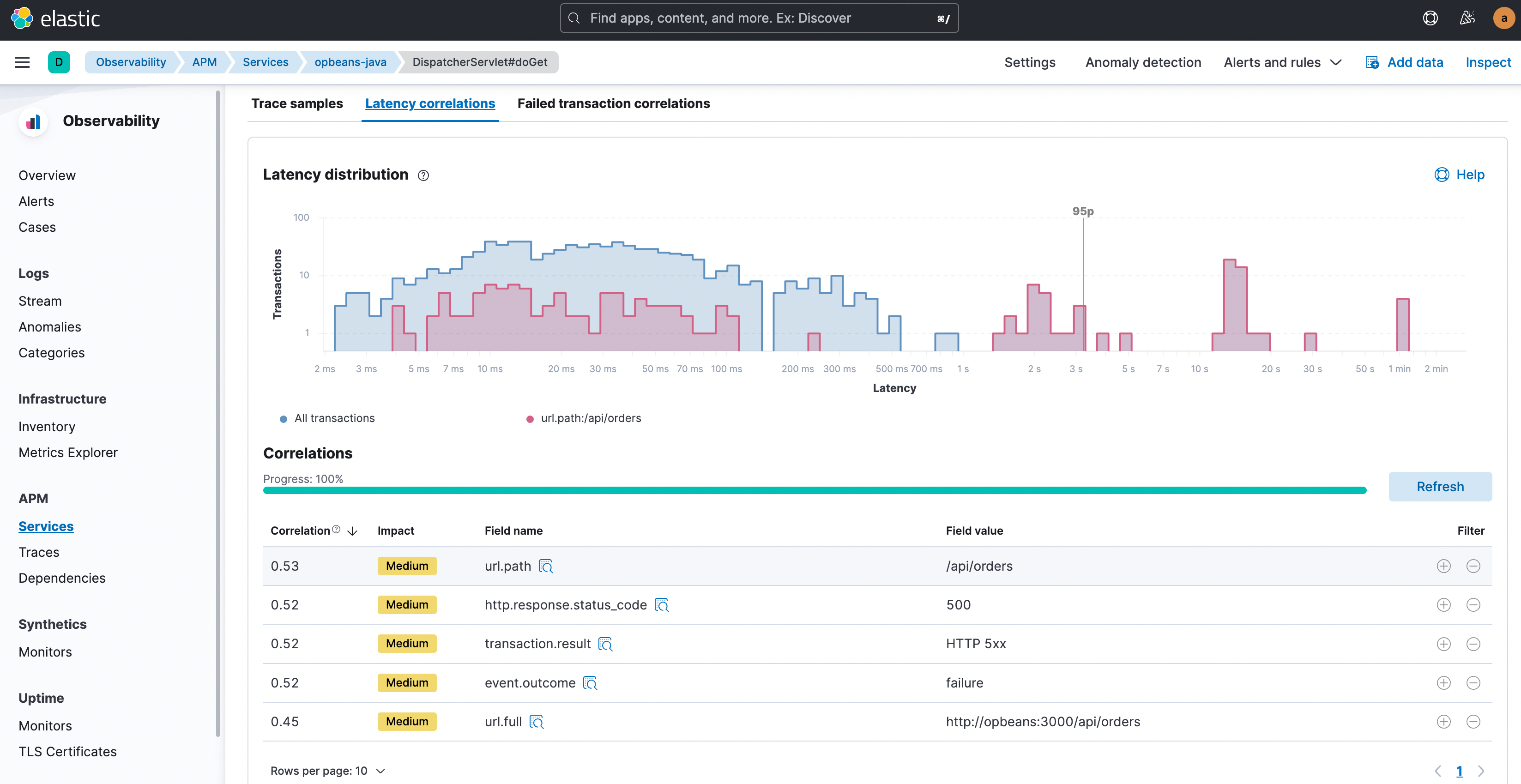

- Latency and error correlations Analyzing data related to latency and error rates to identify correlations between the two, you can spot patterns and relationships between errors and performance issues that can help pinpoint root causes.

Security Analyzing security-related data to identify vulnerabilities and weaknesses in the system is an important aspect of root cause analysis. It can help prevent security breaches and other issues that could impact software performance.

- Unsupervised anomaly detection provides an additional layer of defense Comprehensive security requires multiple layers of threat protection. Unsupervised machine learning identifies deviations from normal activity in your data, without having to specify what's abnormal, and can catch attacks that standard approaches to threat hunting are likely to miss.

- Investigating threats and exploring correlations Analyzing security data related to detected events helps determine whether they represent actual threats, or can be ignored. Security analysts recognize malicious activity by looking at patterns in sessions, event timelines, and diagnostic information from hosts.

Common mistakes to avoid with root cause analysis

Root cause analysis can be incredibly effective for identifying and resolving problems, but there are several common mistakes teams should be aware of:

- Lack of data validation: Failing to validate the data used in your analysis can lead to incorrect conclusions and ineffective solutions.

- Selecting solutions as causes: Issues like lack of training and support or budget constraints are rarely the root cause of a problem. They're far more often the solutions. It's critical to dive deeper to trace a problem to its origins.

- Need to find one cause: There can be many contributing factors that lead to a problem, and it's important to identify all of them, rather than landing on one that's convenient.

- Not involving the right people: Valid, truly effective RCA requires input from all relevant stakeholders, including software developers, testers, and business analysts.

Benefits of root cause analysis

The benefits of root cause analysis in software development are enhanced troubleshooting, reduced costs, and greater efficiency — all of which lead to a better product and a happier customer. Root cause analysis is a critical component of software development, helping teams identify the origins of fundamental errors and how to fix them. RCA also allows teams to stop problems from happening again.

- Helps to prevent problems from recurring: RCA enables teams to implement solutions that address root causes rather than just symptoms. By preventing problems from recurring, teams can save time, reduce costs, and improve the overall quality of their software. For example, a software team may notice that a particular feature of an application is consistently crashing. By performing RCA, they might discover the issue stems from a particular set of user inputs that aren’t being handled properly. With this information, they can implement a correct solution that stops the issue in its tracks.

- Improves process efficiency: By identifying root causes, teams can optimize their processes to prevent similar issues from occurring, leading to increased efficiency, reduced downtime, and a more streamlined development process. If a dev team finds their continuous integration pipeline repeatedly failing due to issues with their test suite, they can perform RCA to find out if the problem is slow-running tests causing the pipeline to time out. Now they can optimize their test suite to avoid similar problems in the future.

- Prevents customer dissatisfaction: Root cause analysis helps teams address issues that could impact customer satisfaction. If, for example, a team receives user complaints about a feature being too slow to load, they might use RCA to determine that the issue is a poorly optimized database query. By implementing solutions to prevent that problem from recurring, like optimizing the query to improve performance, they can deliver a more positive user experience. When software consistently meets customer expectations, it goes a long way in building trust and loyalty, which can ultimately lead to increased revenue and long-term growth.

Tips for performing root cause analysis

- Pull information from multiple sources, and understand your data When performing root cause analysis, data quality, visibility, and comprehension are paramount. Elastic offers a solution that consolidates all your data in one system. You get data visualization in Kibana and interactive tools that allow you to dig deep into observability issues and investigate security incidents.

- Get multiple eyes on the data and the problem by working with a team Elastic features extended support for personalized collaboration in Kibana and O11y, helping you streamline workflows and facilitate escalations with your team.

- Take notes Elastic offers streamlined alerts and case management , allowing you to reach insights faster with richer context for your data and visualizations, including sourcing annotations dynamically from Elasticsearch queries in Kibana. For query-based annotations, you also have the ability to manually annotate Kibana Lens visualization with notes.

Root cause analysis with Elastic

The Elasticsearch Platform and its built-in solutions — Elastic Enterprise Search , Elastic Observability , and Elastic Security — act collectively as a jet engine for facilitating root cause analysis. As the most widely deployed solution for transforming metrics, logs, and traces into actionable IT insights — Elastic Observability enables you to unify observability across your entire digital ecosystem. Further, analysts recognized Elastic Security as a leader in security analytics and SIEM.

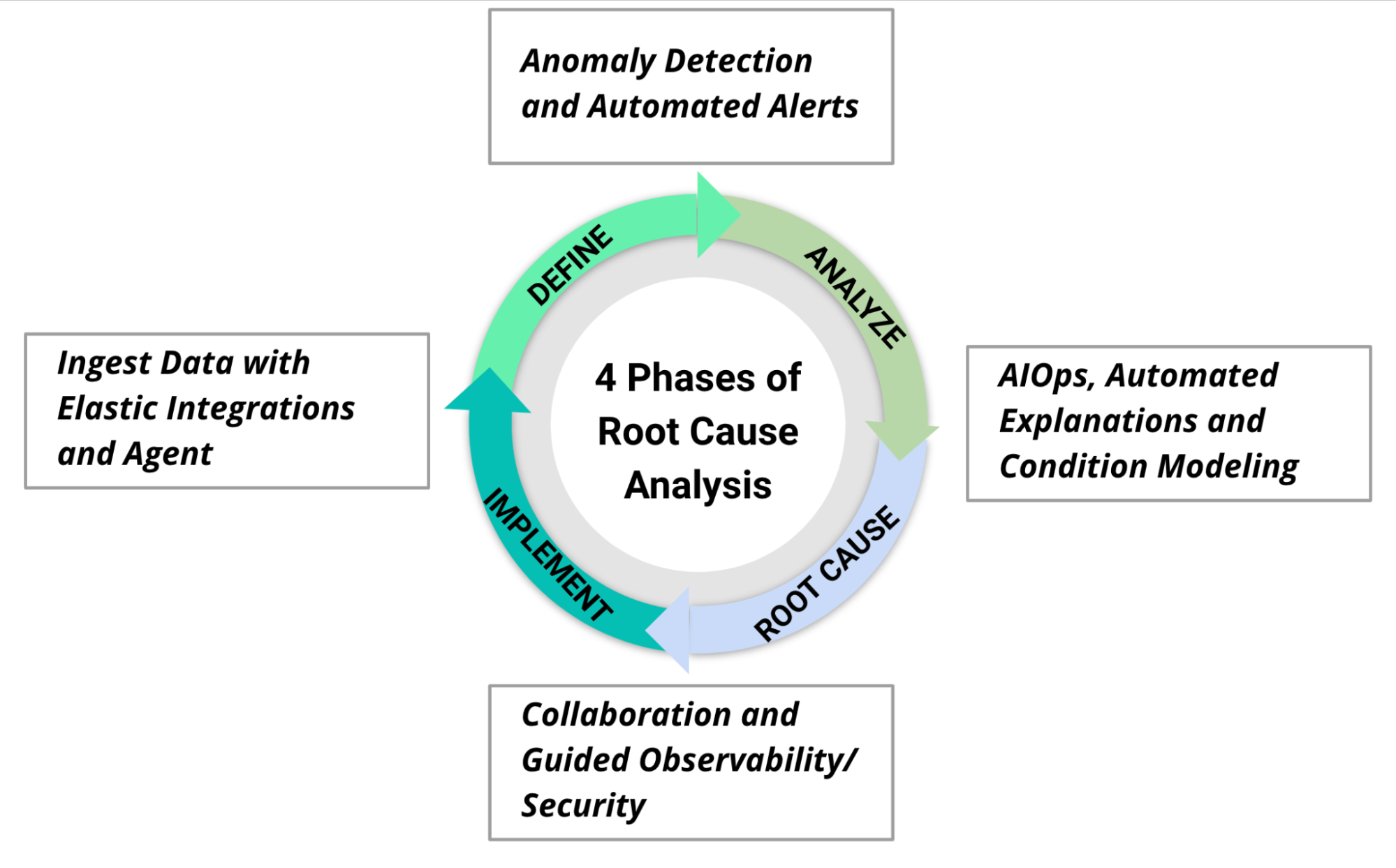

Specifically, the following capabilities accelerate root cause analysis in its various phases:

- Ingest your data with Elastic Agent and hundreds of integrations .

- Receive automated notifications of potential issues using pre-configured alerts and anomaly detection, effectively putting your monitoring on "auto pilot"

- Apply machine learning and AIOps to process large data sets at scale, with interactive features tailor-made to facilitate RCA for observability, including APM correlations and Explain log rate spikes , and for security investigations with features like Session View , Event timeline , and query hosts for diagnostic information using Osquery .

- Determine causal factors using guided journeys and collaborate on root cause and appropriate solutions to fix and prevent the problems using Elastic case management .

To help your team get the most out of root cause analysis, start a free trial and discover what Elastic can do for you.

Root cause analysis resources

- Root cause analysis for logs

- Automate anomaly detection and accelerate root cause analysis with AIOps

- Why you need AIOps as part of your observability strategy

- Elastic Security for SIEM & security analytics

- Elastic Security for automated threat protection

- Accelerate security investigations with machine learning and interactive root cause analysis in Elastic

- Apply Elastic to root cause analysis in manufacturing

- Predictive maintenance in industrial IoT

Root Cause Analysis

Used throughout every major industrial and business sector, sologic root cause analysis (rca) is an evidence-based, problem-solving method based on cause & effect logic., what is root cause analysis (rca).

Root Cause Analysis (RCA) is a structured problem solving method. The aim of RCA is to identify, understand and solve the deeper ‘root causes’ of problems. RCA is built on the principle that causal relationships exist for all events. By understanding these we can move beyond the symptoms and address the root causes at source .

For many of us, when there is a problem at work, it is difficult to get beyond immediate symptoms, meaning that the underlying causes have not been dealt with and will need fixing time and time again. A scenario we often refer to as “fire-fighting”.

The Root Cause Analysis method or ‘RCA’ as it is often abbreviated to, is a widely used technique that helps people get beyond the symptoms of a problem and reveal the, often hidden, and multiple root causes.

There are a variety of Root Cause Analysis processes to choose from, some are quick and easy, such as 5 Whys, others are longer and more complex such as FMEA and Ishikawa. The Sologic RCA methodology is quick to learn, logical and scalable. It is also universal in that it can be applied to any problem, in any sector .

Who is responsible for Root Cause Analysis?

Anyone can lead an RCA - especially if they are using the right method and tools. Best practice in RCA shows us that subject matter expertise in the area being investigated is not usually required. An expert Root Cause Analysis training course can ensure your RCA Champions have the skills they need.

The RCA Lead or Facilitator usually assembles the RCA Team and gathers the information required from a variety of sources. They then use this information to determine the three main components of any Root Cause Analysis:

- What happened?

- Why did it happen?

- What is required to prevent this problem from happening again?

These investigations may be recorded as individual reports or form part of a formal company-wide RCA Program .

How to conduct an RCA?

When an incident occurs it’s important that it is understood in a logical, objective and critical manner. To do this successfully we must gather and manage the available evidence. Once collected in full we can define the problem and record its impacts. High quality cause and effect analysis adds a deeper understanding, leading to targeted and more effective solutions. If these are clearly documented and shared an organisation can learn from past failures and prevent future problems.

What are the steps in Root Cause Analysis?

5 Step Sologic Root Cause Analysis Method

RCA Step 1: Gather and Manage Data

An RCA investigation should be based on facts – making sure the RCA is evidence-based helps ensure accuracy. High-quality evidence helps ensue your RCA is based on known data, not supposition.

RCA Step 2: Create a Problem Statement

RCA Step 3: Analyse Cause and Effect

What were the causes of your incident? Cause and Effect Analysis reveals that actions and conditions are interrelated. A change in one area creates a change another. These coincide to create the specific problem you are investigating. The following common Root Cause Analysis Tools are favoured amongst those looking to conduct an effective visual analysis: 5 Whys Cause & Effect Diagrams (Continued Below) Failure Mode & Effects Analysis FMEA Fishbone Ishikawa Lean / Six Sigma In practice, the majority Root Cause Analysis specialists prefer the 5 Whys tool for simple problems and Cause and Effect charts for complex problems.

What is a cause and effect diagram?

RCA Step 4: Generate Solutions

RCA Step 5: Complete and Share a Final Report

Once the analysis is complete, we assemble a final RCA report. The final report is the communication vehicle for a broader audience so that others can recognize and mitigate risks in their areas. The report also becomes the ‘lesson learned’ document enabling the new knowledge to be shared with future employees. Cause and Effect charts are scalable and transferable. The logic is applicable to small recurrent issues as well as large, one-off, never-events. Visit our root cause analysis examples pages to see examples covering areas such as safety, quality, reliability, operations and compliance.

How To Make a Simple Cause and Effect Chart

Root Cause Analysis Software Sologic’s Root Cause Analysis software tool, Causelink allows problem-solving professionals to investigate events in a simple, standardized and evidence-based manner. Causelink supports 5 Whys and Cause and Effect charting, encourages the breaking of causal chains and pinpoints the effective solutions that overcome repeat failures. Further Root Cause Analysis reading

- Root cause analysis training

- Root cause analysis ebooks

- Root cause analysis examples and templates

- Root cause analysis case studies

- Root cause analysis in healthcare and nursing

- Root cause analysis in construction and engineering

Root Cause Problem Solving - Methods and Tools PD530931

Topics: Management and Organization Management and Organization , Failure analysis , Analysis methodologies

How do you solve a problem? Do you find yourself using quick and easy solutions or a structured methodology? Too often, organizations tend to seek quick solutions to a problem without adequately addressing its underlying cause. These decisions often result in solutions that don't work or aren't sustainable, often wasting time, effort, and money. To combat these issues and adopt a fresh approach, teams can use the methods and tools of root cause problem solving. By first viewing a problem as an opportunity for improvement, the team can then identify the problem's root cause or causes, and implement solutions to prevent the problem's reoccurrence.

This six module course introduces the Root Cause Problem Solving approach. It explains how using Root Cause analysis can help improve operational and financial performance by identifying root causes and implementing solutions to significant or recurring problems. This methodology is used by many major automotive manufacturers to improve quality and customer satisfaction, reduce operation costs, and provide greater employee knowledge of work processes.

Participants will become familiar with the eight steps of the Root Cause Problem Solving approach, learning the key actions completed in each step and interacting with examples and scenarios that demonstrate how each step functions to solve problems and keep them from reoccurring in an organization. Participants will also be supplied with tools that assist with the completion of each step that they can use in their own problem-solving efforts on-the-job.

By participating in this eLearning course, you'll be able to:

- Explain why root cause analysis using the 8-step problem solving methodology is more effective than non-structured problem solving efforts

- Define the difference between a problem, symptom, cause, and root cause

- Use tools and techniques to solve problems

- Evaluate the effectiveness of problems solving efforts

- Describe the role of problem solving in continuous improvement

Materials Provided

- 90 days of online single-user access (from date of purchase) to the six hour presentation

- Integrated knowledge checks to reinforce key concepts

- Follow-up to your content questions

- 1.0 CEUs*/Certificate of Achievement (upon completion of all course content and a score of 70% or higher on the learning assessment)

*SAE International is authorized by IACET to offer CEUs for this course.

Is this On Demand Course for You?

This course is applicable to those directly working in or responsible for performance improvement of any definable, repetitive process (e.g., manufacturing, design, logistics, purchasing, sales, or distribution), including: manufacturing managers, supervisors, and team leaders; manufacturing engineers; design engineers; quality engineers and technicians; technical managers; project team leaders; problem solving and quality improvement facilitators; anyone whose role includes problem solving: supervisors and lead personnel.

Testimonial

"Thank you for introducing me to the SAE Root Cause Problem Solving course. Quality has been my vocation for 11 years and this course opened my eyes to so many things I have been missing. It should be required for anyone in the quality business." Chuck Hartshorn Quality Manager

For More Details

Email [email protected] , or call 1-877-606-7323 (U.S. and Canada) or 724-776-4970 (outside US and Canada).

- Windows 7, 8, 10 (other operating systems and mobile platforms are not supported but may work)

- Internet Explorer 11, Mozilla Firefox 37, Google Chrome 42 (other browsers are not supported but may work)

- Broadband-1Mbps minimum

Root-Cause Problem Solving in an Industry 4.0 Context

23 citations

View 1 citation excerpt

Additional excerpts

... Therefore, RCA has been used in numerous areas and is usually concerned with finding the root causes of events with safety, health, environmental, quality, reliability, production, and performance impacts [10], [11]. ...

11 citations

10 citations

7 citations

4 citations

50 citations

35 citations

View 1 reference excerpt

"Root-Cause Problem Solving in an In..." refers background in this paper

... 0 Background Problem solving is the process of working through the details of a problem by applying appropriate technology, tools, and decision-making techniques to identify a root cause and to implement a solution, and RCA is a step-by-step process of observing, investigating, analyzing, and determining the source of a problem to prevent a recurrence of the same problem or—even worse—a negative spiral of wider business impacts [1]. ...

24 citations

"Root-Cause Problem Solving in an In..." refers methods in this paper

... By brainstorming together with the basic tools of the RCA methodology [2], [3], design, production, and quality control managers share data, findings, and observations to identify a problem’s root cause [4]. ...

13 citations

... These problems are placed into six categories: machines, materials, methods, measurements, people, andmother nature [8]. ...

... 0 may include some or all of the following nine technological elements: 1) big data analytics; 2) autonomous robots; 3) product simulation testing; 4) horizontal and vertical system integration; 5) the industrial IOT (IIoT); 6) cybersecurity; 7) the cloud; 8) additive manufacturing; 9) augmented reality [5]. ...

Related Papers (5)

Trending questions (1).

The paper does not explicitly mention the benefits of identifying the root cause of a problem.

Ask Copilot

Related papers

Contributing institutions

Related topics

- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- *New* Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

Root Cause Analysis: What It Is & How to Perform One

- 07 Mar 2023

The problems that affect a company’s success don’t always result from not understanding how to solve them. In many cases, their root causes aren’t easily identified. That’s why root cause analysis is vital to organizational leadership .

According to research described in the Harvard Business Review , 85 percent of executives believe their organizations are bad at diagnosing problems, and 87 percent think that flaw carries significant costs. As a result, more businesses seek organizational leaders who avoid costly mistakes.

If you’re a leader who wants to problem-solve effectively, here’s an overview of root cause analysis and why it’s important in organizational leadership.

Access your free e-book today.

What Is Root Cause Analysis?

According to the online course Organizational Leadership —taught by Harvard Business School professors Joshua Margolis and Anthony Mayo— root cause analysis is the process of articulating problems’ causes to suggest specific solutions.

“Leaders must perform as beacons,” Margolis says in the course. “Namely, scanning and analyzing the landscape around the organization and identifying current and emerging trends, pressures, threats, and opportunities.”

By working with others to understand a problem’s root cause, you can generate a solution. If you’re interested in performing a root cause analysis for your organization, here are eight steps you must take.

8 Essential Steps of an Organizational Root Cause Analysis

1. identify performance or opportunity gaps.

The first step in a root cause analysis is identifying the most important performance or opportunity gaps facing your team, department, or organization. Performance gaps are the ways in which your organization falls short or fails to deliver on its capabilities; opportunity gaps reflect something new or innovative it can do to create value.

Finding those gaps requires leveraging the “leader as beacon” form of leadership.

“Leaders are called upon to illuminate what's going on outside and around the organization,” Margolis says in Organizational Leadership , “identifying both challenges and opportunities and how they inform the organization's future direction.”

Without those insights, you can’t reap the benefits an effective root cause analysis can produce because external forces—including industry trends, competitors, and the economy—can affect your company’s long-term success.

2. Create an Organizational Challenge Statement

The next step is writing an organizational challenge statement explaining what the gap is and why it’s important. The statement should be three to four sentences and encapsulate the challenge’s essence.

It’s crucial to explain where your organization falls short, what problems that poses, and why it matters. Describe the gap and why you must urgently address it.

A critical responsibility is deciding which gap requires the most attention, then focusing your analysis on it. Concentrating on too many problems at once can dilute positive results.

To prioritize issues, consider which are the most time-sensitive and mission-critical, followed by which can make stakeholders happy.

3. Analyze Findings with Colleagues

It's essential to work with colleagues to gain different perspectives on a problem and its root causes. This involves understanding the problem, gathering information, and developing a comprehensive analysis.

While this can be challenging when you’re a new organizational leader, using the double helix of leadership —the coevolutionary process of executing organizational leadership's responsibilities while developing the capabilities to perform them—can help foster collaboration.

Research shows diverse ideas improve high-level decision-making, which is why you should connect with colleagues with different opinions and expertise to enhance your root cause analysis’s outcome.

4. Formulate Value-Creating Activities

Next, determine what your company must do to address your organizational challenge statement. Establish three to five value-creating activities for your team, department, or organization to close the performance or opportunity gap you’ve identified.

This requires communicating organizational direction —a clear and compelling path forward that ensures stakeholders know and work toward the same goal.

“Setting direction is typically a reciprocal process,” Margolis says in Organizational Leadership . “You don't sit down and decide your direction, nor do you input your analysis of the external context into a formula and solve for a direction. Rather, setting direction is a back-and-forth process; you move between the value you'd like to create for customers, employees, investors, and your grasp of the context.”

5. Identify Necessary Behavior Changes

Once you’ve outlined activities that can provide value to your company, identify the behavior changes needed to address your organizational challenge statement.

“Your detective work throughout your root cause analysis exposes uncomfortable realities about employee competencies, organizational inefficiencies, departmental infighting, and unclear direction from leadership at multiple levels of the company,” Mayo says in Organizational Leadership .

Factors that can affect your company’s long-term success include:

- Ineffective communication skills

- Resistance to change

- Problematic workplace stereotypes

Not all root cause analyses reveal behaviors that must be eliminated. Sometimes you can identify behaviors to enhance or foster internally, such as:

- Collaboration

- Innovative thinking

- Creative problem-solving

6. Implement Behavior Changes

Although behaviors might be easy to pinpoint, putting them into practice can be challenging.

To ensure you implement the right changes, gauge whether they’ll have a positive or negative impact. According to Organizational Leadership , you should consider the following factors:

- Motivation: Do the people at your organization have a personal desire for and commitment to change?

- Competence: Do they have the skills and know-how to implement change effectively?

- Coordination: Are they willing to work collaboratively to enact change?

Based on your answers, decide what behavior changes are plausible for your root cause analysis.

7. Map Root Causes

The next step in your analysis is mapping the root causes you’ve identified to the components of organizational alignment. Doing so helps you determine which components to adjust or change to implement employee behavior changes successfully.

Three root cause categories unrelated to behavior changes are:

- Systems and structures: The formal organization component, including talent management, product development, and budget and accountability systems

- People: Individuals’ profiles and the workforce’s overall composition, including employees’ skills, experience, values, and attitudes

- Culture: The informal, intangible part of your organization, including the norms, values, attitudes, beliefs, preferences, common practices, and habits of its employees

8. Create an Action Plan

Using your findings from the previous steps, create an action plan for addressing your organizational problem’s root cause and consider your role in it.

To make the action plan achievable, ensure you:

- Identify the problem’s root cause

- Create measurable results

- Ensure clear communication among your team

“One useful way to assess your potential impact on the challenge is to understand your locus of control,” Mayo says in Organizational Leadership , “or the extent to which you can personally drive the needed change or improvement.”

The best way to illustrate your control is by using three concentric circles: the innermost circle being full control of resources, the middle circle representing your ability to influence but not control, and the outermost circle alluding to shifts outside both your influence and control.

Consider these circles when implementing your action plan to ensure your goals don’t overreach.

The Importance of Root Cause Analysis in Organizational Leadership

Root cause analysis is a critical organizational leadership skill for effectively addressing problems and driving change. It helps you understand shifting conditions around your company and confirm that your efforts are relevant and sustainable.

As a leader, you must not only effect change but understand why it’s needed. Taking an online course, such as Organizational Leadership , can enable you to gain that knowledge.

Using root cause analysis, you can identify the issues behind your organization’s problems, develop a plan to address them, and make impactful changes.

Are you preparing to transition to a new leadership role? Enroll in our online certificate course Organizational Leadership —one of our leadership and management courses —and learn how to perform an effective root cause analysis to ensure your company’s long-term success. To learn more about what it takes to be an effective leader, download our free leadership e-book .

About the Author

Root Cause Analysis: A Complete Guide With Examples (2023)

Root Cause Analysis (RCA) is not just a structured method of problem-solving; it's a vital component of organisational leadership. The goal of RCA is to fully understand what caused an issue, allowing for effective corrective actions.

One of the first steps in a successful RCA is identifying performance or opportunity gaps within an organisation. These gaps reflect ways in which an organisation falls short or fails to deliver on its capabilities. RCA helps in pinpointing these gaps, thereby allowing for more targeted solutions.

This article will take you through the benefits of RCA and the three basic types of root causes behind workplace incidents. We’ll then explore the two popular methodologies for RCA and how you can use the RCA methodology to identify them.

Finally, we’ll share tools and best practices to help you implement a robust RCA framework so you can develop a comprehensive problem-solving process for safety and risk management in your organisation.

Read on to discover how RCA can revolutionise your approach to problem-solving and risk management.

The benefits of Root Cause Analysis (RCA)

Without a structured RCA framework for resolving incidents, organisations risk implementing superficial quick fixes that may address some of the symptoms but not the core problems.

An effective RCA methodology helps an organisation's Health & Safety (H&S) team to identify the root causes of a reported incident in the workplace, which is essential to assign effective preventive or corrective actions . Implementing this framework have many benefits:

- Save time, money, and resources because they can identify and invest in the right preventive and corrective actions.

- Prevent the incident from recurring because they can correct the factors causing the issues.

- Prevent more damage or injury caused by a recurring incident.

- Prevent more downtime caused by a recurring incident.

- Boost productivity because they don’t have to revisit the same incident and spend extra time trying to solve the underlying issues.

The three basic types of root cause

There are three fundamental types of root causes:

- Environmental root cause These are causes related to external factors such as moisture levels, weather, or geography.

- Individual root cause These are causes related to an individual’s behaviour, personal choices, ability, or circumstance.

- Organisational root cause These are causes involving internal organisational structure or processes.

The two popular RCA frameworks

A study by Baylor University Medical Center Proceedings identified two popular RCA frameworks. We will cover each one with an example.

#1: The "5 Whys" Method

This is perhaps the most popular RCA technique because of its simplicity. The method is to ask why something happened at least five times. Here’s an example of how it works.

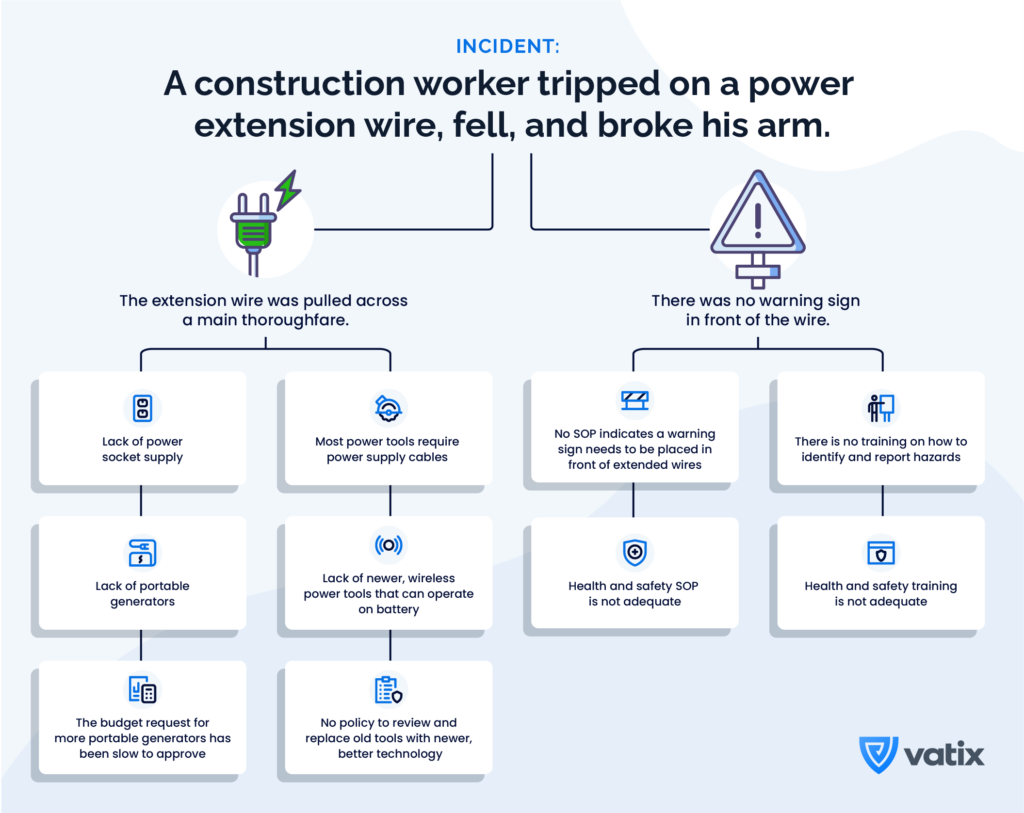

Incident: A construction worker fell and broke his arm.

- “Ask Why” #1: Why did he fall? Answer: He tripped on a wire

- “Ask Why” #2: Why was the wire on the ground? Answer: It was an extension wire needed to supply power to a tool on the other side.

- “Ask Why” #3: Why was the wire pulled across a thoroughfare? Answer: There was no power socket on the other side.

- “Ask Why” #4: Why is there only one power socket in that area? Answer: There aren’t enough portable generators on the site.

- “Ask Why” #5: Why aren’t enough portable generators on the site? Answer: The application requesting the budget to rent a few more portable generators is pending approval.

Using this RCA technique, we’ve identified the actual root cause to be an organisational root cause. The solution for the organisation is to improve the process of approving budgets.

Speeding up the process of approving budgets doesn’t just help prevent future similar incidents. It may also bring the added benefit of improving productivity when construction workers can quickly get what they need to perform their tasks.

Without using this RCA technique, one could have soon concluded that it was solely an environmental or individual root cause. Any corrective actions in these areas are likely to be ineffective or short-term.

#2: Causal Tree

A causal tree is used to evaluate other possible causes that contributed to the incident. This can help organisations identify other possible preventive or corrective actions. Here’s an example of how a causal tree could look like for the same incident example above:

Organisations can explore other possible root causes that need addressing using a causal tree. This RCA methodology is beneficial for identifying root causes across environmental, individual, and organisational categories. Another advantage of using the causal tree framework is that it allows organisations to implement short-term solutions to prevent incidents while they take more time to find answers to more prominent issues. For example, the construction company can implement the short-term solution of placing warning signs in front of extended wires on the ground. Meanwhile, the organisation will look into solving the other root causes identified, such as improving the budget approval process and hazard reporting training.

Common Mistakes to Avoid in Root Cause Analysis

Root Cause Analysis (RCA) can be highly effective in addressing workplace safety issues when done correctly.

However, there are some common mistakes that organisations make when conducting RCA.

Mistake #1: Jumping to conclusions

One of the most common mistakes is jumping to conclusions without thoroughly examining the available information. This often leads to implementing quick fixes that do not address the root cause of the problem.

Tip: Ensure that you take the time to gather all relevant information and systematically work through the RCA process to identify the underlying cause.

Mistake #2: Focusing only on individual errors

Another mistake is solely blaming individuals for incidents without considering the broader organisational context. This can lead to a culture of blame and an unwillingness to report incidents in the future.

Tip: While it is essential to consider individual factors, also examine organisational root causes and environmental factors that may have contributed to the incident. This will help to create a more comprehensive understanding of the issue and lead to more effective solutions.

Mistake #3: Neglecting to involve the right people

One common mistake organisations make is neglecting to involve the right people in the RCA process. A successful RCA requires input from various stakeholders, including employees directly involved in the incident, supervisors, and management. Collaborative analysis helps in collecting a variety of viewpoints and promotes a sense of collective accountability for workplace safety.

Tip: Involving all pertinent stakeholders in the RCA process is crucial, as it aids in collecting a variety of viewpoints and promotes a sense of collective accountability for workplace safety.

Mistake #4: Inadequate documentation

Poor documentation of the RCA process and its outcomes can lead to a lack of accountability and hinder the implementation of corrective actions.

Tip: Document every step of the RCA process, including the incident description, investigation, root cause identification, and proposed corrective actions. This will help ensure that all stakeholders are aware of their responsibilities and can track the progress of the implemented solutions.

Mistake #5: Failing to follow up on corrective actions

Implementing corrective actions is only one part of the RCA process. Organisations sometimes fail to follow up on these actions, which can lead to a recurrence of the incident or issue.

Tip: Establish a system to monitor the progress of corrective actions and evaluate their effectiveness. Regularly review the implemented solutions and make any necessary adjustments to ensure that the root cause is fully addressed and the risk of recurrence is minimised.

How to implement a robust RCA framework

To enhance workplace safety, it is crucial to establish a strong RCA framework within your organisation.

These are the following steps to implement such a framework:

- Train the H&S team on how to use the different types of RCA frameworks.

- Make it easy for employees to report incidents and other events like near misses.

- Update the new employee training, health and safety training, and SOP guides on submitting incident reports and conducting RCA.

- Conduct regular health and safety training sessions.

- Creating an action plan: outline the steps to be taken, the stakeholders involved, and the timeline for implementation

The importance of high-quality incident and hazard reports

The effectiveness of any Root Cause Analysis (RCA) relies heavily on the input data's accuracy and quality. Therefore, it is imperative to have a reliable incident reporting system in place to ensure the provision of high-quality input data.

Here are the characteristics of a high-quality incident report:

- Records the incident's time, date, and location.

- Is honest, clear, and concise.

- Provides accurate information that doesn’t leave out important facts.

- Provide as much context as possible.

- It is written in a first-person, objective observation of what happened, not what they think might have happened.

To write an accurate incident report, employees should be encouraged to start writing the report as soon as possible.

Delaying writing the report can lead to inaccurate reports or reports without enough detail because the memory gets fuzzy. Whenever possible or relevant, employees should also attach photos for additional context.

To help you navigate the complexities of incident reporting, we strongly recommend downloading our free checklist and comprehensive guide .

Best practices to improve incident reporting and RCA

One of the best practices to improve the quality of incident reports is digitalising the incident reporting process.

Here’s an example of how Vatix’s incident reporting systems can improve the quality of workplace incident reports and RCA.

- Higher quality incident reports Our mobile platform makes it easy for employees to report an incident from anywhere without the friction of filling out and submitting a paper form. Facilitating on-the-spot reporting for employees minimises the likelihood of postponing or neglecting to report incidents or other events. Faster reporting of incidents also improves the quality of the report. Employees are more likely to record details with better descriptions and upload photos directly from their mobile devices, improving the data needed for an effective RCA.

- Customise incident types to an organisation’s specific needs Our incident reporting software allows organisations to customise the types of incidents employees can report. These templates eliminate the need to print out, distribute, and file multiple forms.

- Easily customise the incident reporting template to capture relevant information. With our incident reporting software, organisations can customise the incident reporting forms to ensure employees submit all required and relevant information.

- Real-time reporting and location tracking for faster response Paper-based incident reporting causes a lot of delays and it can take hours before supervisors or managers can view the incident reports. With real-time mobile incident reporting, employees can submit incidents on-the-spot and the H&S team will be alerted with a location so they can respond to the incident within minutes. In some cases, faster response time with location tagging can be the difference between life and death.

- Easy to get more context at a glance Unlike manual paper-and-pen incident reporting forms, employees can easily add photographs to the incident report directly from their mobile. The incident reporting app also logs the location and provides visual maps for additional context at a glance.

Improve workplace health & safety processes

By combining mobile incident reporting with an effective RCA strategy, organisations can respond to incidents faster and more effectively to create a positive safety culture, leading to increased productivity and decreased risk of accidents and injuries. Talk to our sales here to learn more about how you can customise our mobile incident reporting software to fit your business and improve workplace safety.

Related Articles

Subscribe to our newsletter, subscribe to our newsletter.

Root-Cause Problem Solving in an Industry 4.0 Context

Publisher URL: http://ieeexplore.ieee.org/document/8960381

DOI: 10.1109/emr.2020.2966980

Keeping up-to-date with research can feel impossible, with papers being published faster than you'll ever be able to read them. That's where Researcher comes in: we're simplifying discovery and making important discussions happen. With over 19,000 sources, including peer-reviewed journals, preprints, blogs, universities, podcasts and Live events across 10 research areas, you'll never miss what's important to you. It's like social media, but better. Oh, and we should mention - it's free.

Researcher displays publicly available abstracts and doesn’t host any full article content. If the content is open access, we will direct clicks from the abstracts to the publisher website and display the PDF copy on our platform. Clicks to view the full text will be directed to the publisher website, where only users with subscriptions or access through their institution are able to view the full article.

IMAGES

VIDEO

COMMENTS

Root cause analysis (RCA) is a highly effective methodology for product design teams and manufacturing managers to engage in creative problem solving by utilizing the tools of the Fourth Industrial Revolution-Industry 4.0. This article outlines the RCA problem-solving process as it is applied to detect and resolve problems in a consumer product manufacturing setting. This article presents a ...

Abstract. Root Cause Analysis (RCA) is a highly effective methodology for product design teams and manufacturing managers to engage in creative problem solving utilizing the tools of the Fourth ...

DOI: 10.1109/EMR.2020.2966980 Corpus ID: 214116543; Root-Cause Problem Solving in an Industry 4.0 Context @article{Vo2020RootCausePS, title={Root-Cause Problem Solving in an Industry 4.0 Context}, author={Brian Vo and Elif Kongar and Manuel F. Su{\'a}rez-Barraza}, journal={IEEE Engineering Management Review}, year={2020}, volume={48}, pages={48-56} }

This document discusses using root cause analysis (RCA) for problem solving in an Industry 4.0 context. It outlines the five steps of the RCA problem solving process: 1) Identifying and defining the problem, 2) Assessing the root cause, 3) Developing and implementing solutions, 4) Monitoring results and preventing recurrence, 5) Sharing lessons. It then provides a case study example of how a ...

Ops 4.0. April 15, 2019 To improve, organizations must consistently seek out and solve their problems—an insight that underpins lean management 's emphasis on root-cause problem solving (RCPS). Indeed, companies that have used RCPS to build a problem-solving culture that lasts are able to avoid continuous firefighting by effectively ...

This paper describes a subset of Industry 4.0, namely, Quality 4.0. Industry 4.0, has brought with it many changes to industry and changes that will directly impact root cause analysis. Massive ...

Vo, B., Kongar, E., & Suarez-Barraza, M. F. (2020). Root-Cause Problem Solving in an Industry 4.0 Context. IEEE Engineering Management Review, 1-1. doi:10.1109/emr ...

The root cause usually relates to the processes or structure of the organisation, such as how work is defined, distributed or how outcomes are measured. These processes and structures often inform how people operate and solve problems, often implicitly influencing the behaviour - the 'culture' of an organisation. This makes any problems ...

The RCA problem-solving process as it is applied to detect and resolve problems in a consumer product manufacturing setting, implemented as part of a wider continuous improvement effort. Root cause analysis (RCA) is a highly effective methodology for product design teams and manufacturing managers to engage in creative problem solving by utilizing the tools of the Fourth Industrial Revolution ...

The first goal of root cause analysis is to discover the root cause of a problem or event. The second goal is to fully understand how to fix, compensate, or learn from any underlying issues within the root cause. The third goal is to apply what we learn from this analysis to systematically prevent future issues or to repeat successes.

The Importance of Root Cause Analysis in Manufacturing In the context of manufacturing, Root Cause Analysis (RCA) is a crucial tool for solving problems, improving processes, and boosting overall ...

Root cause analysis (RCA) is a proven troubleshooting technique used by software development teams to identify and resolve problems at their core, rather than attempting to treat symptoms. Root cause analysis is a structured, step-by-step process designed to seek out primary, underlying causes by gathering and analyzing relevant data and ...

The Importance of Root Cause Analysis in Manufacturing. In the context of manufacturing, Root Cause Analysis (RCA) is a crucial tool for solving problems, improving processes, and boosting overall ...

Root Cause Analysis (RCA) is a structured problem solving method. The aim of RCA is to identify, understand and solve the deeper 'root causes' of problems. RCA is built on the principle that causal relationships exist for all events. By understanding these we can move beyond the symptoms and address the root causes at source.

Root cause analysis is a problem-solving approach that uses the analogy of roots and blooms to model cause-and-effect relationships. Rather than focusing on what's above the surface, root cause analysis troubleshoots solutions to problems by analyzing what is causing them. Note. Similarly to exploratory research, it's important to remember ...